Vortex separation device and control method thereof

A separation device and control method technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of high labor intensity, large cutting fluid reserves, large consumption and waste, etc., to achieve good cooling effect, avoid Reserve and take up space, improve the effect of recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

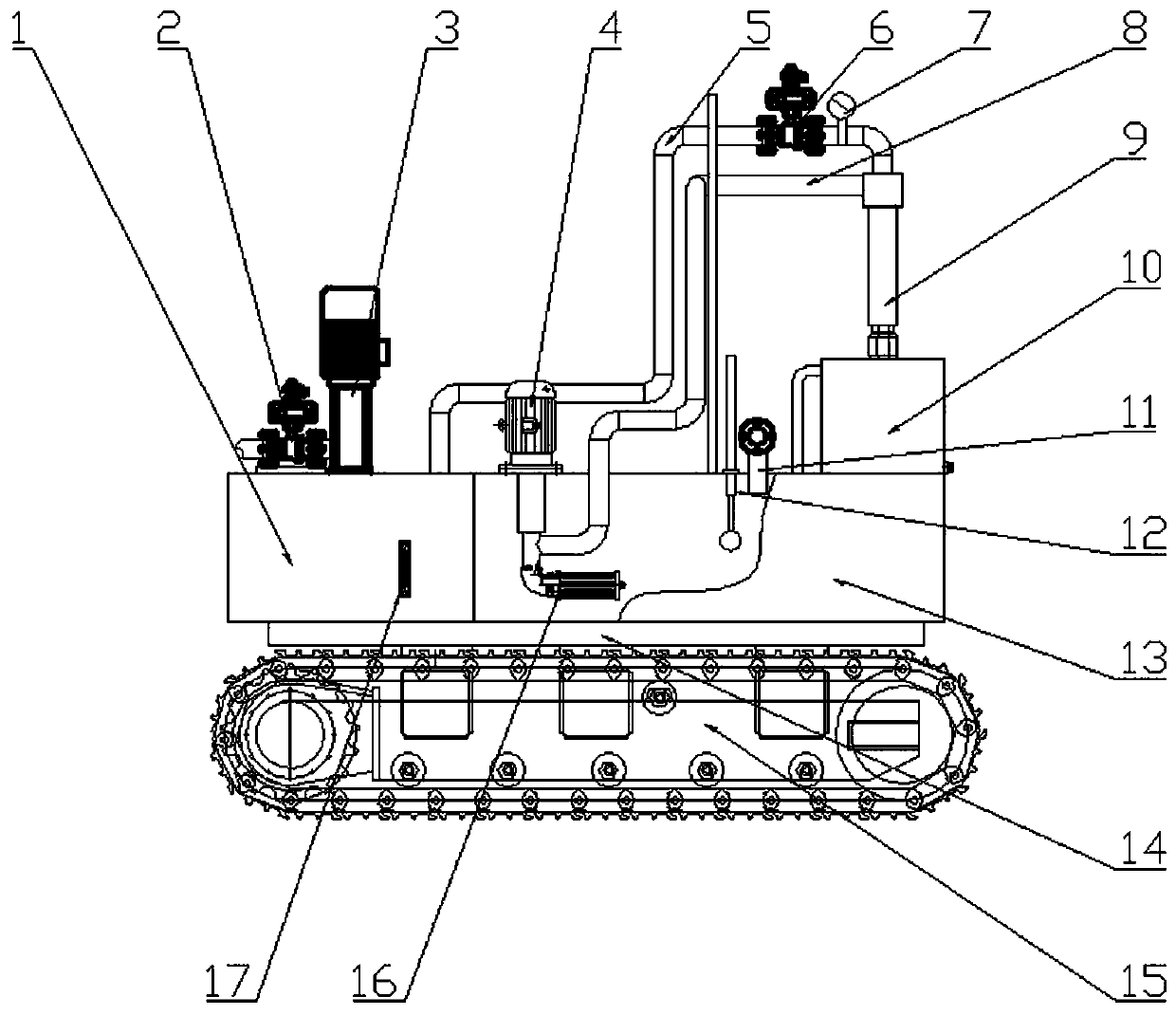

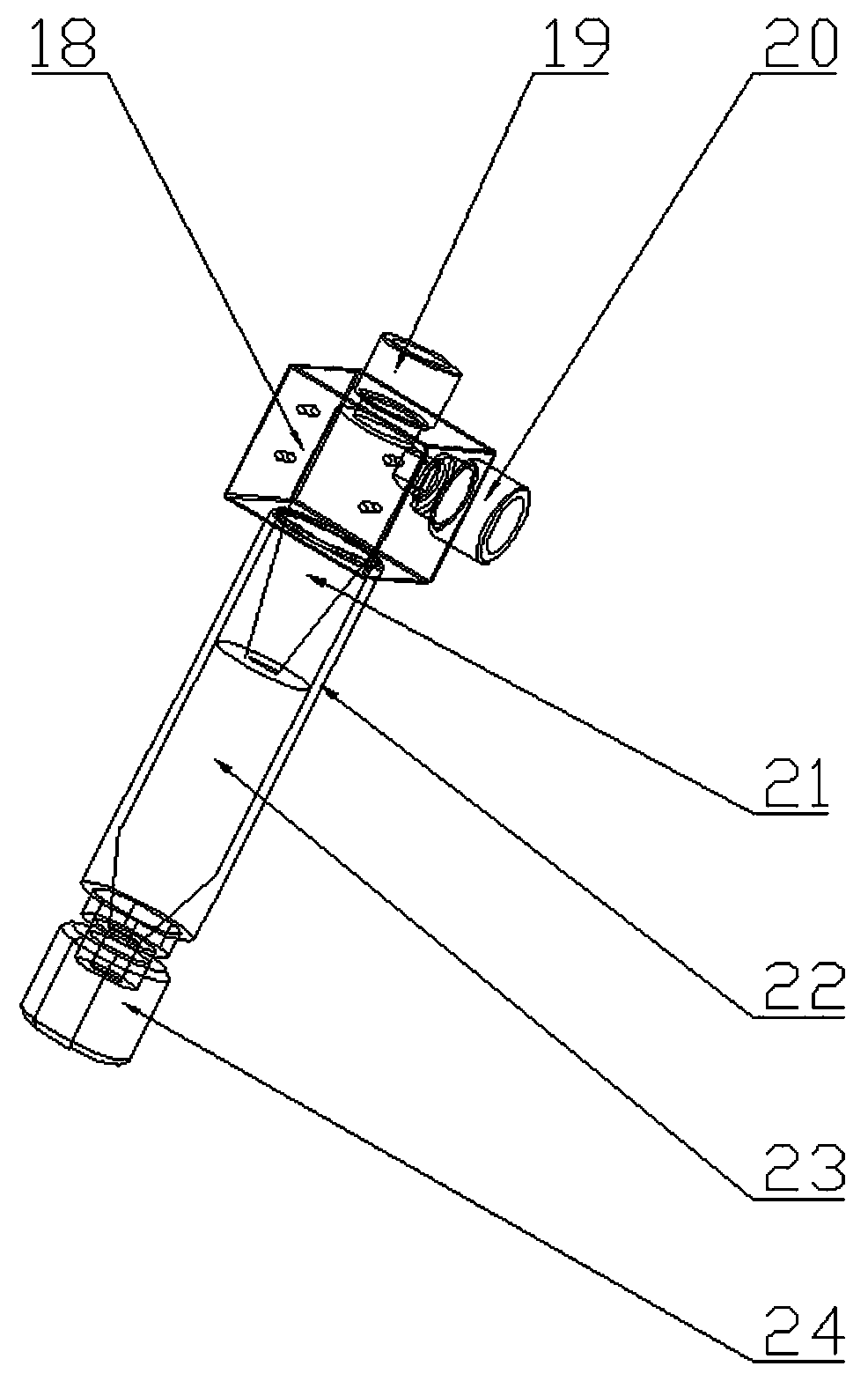

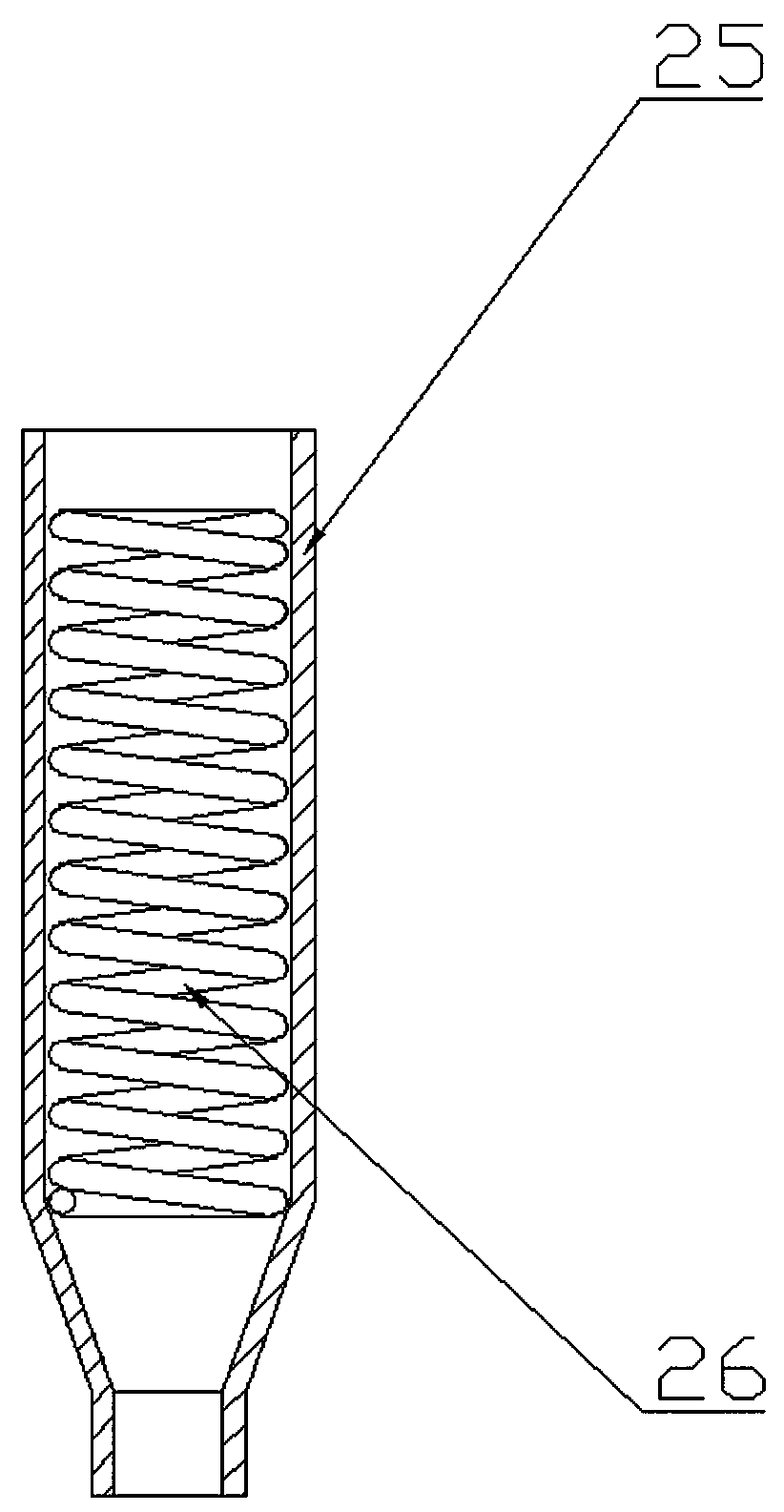

[0028] Example: such as figure 1 and 2 As shown, a vortex separation device includes a liquid storage tank 13, and the liquid storage tank 13 is provided with an infusion pump 4 that is flanged to communicate with the infusion tube 8 and is fixed. The lower end of the infusion pump 4 extends into the liquid storage tank 13, The lower end of the infusion pump 4 is provided with a liquid suction oil filter 16 which is fixedly threaded and sealed with the infusion pump 4 , and a float type liquid level gauge 12 is arranged between the infusion pump 4 and the liquid inlet pipe 11 . A clean liquid tank 1 is provided on the side of the liquid storage tank 13, and the upper end of the clean liquid tank 1 is provided with a liquid supply pump 3 that is flange-type connected with the clean liquid tank 1 and extends int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com