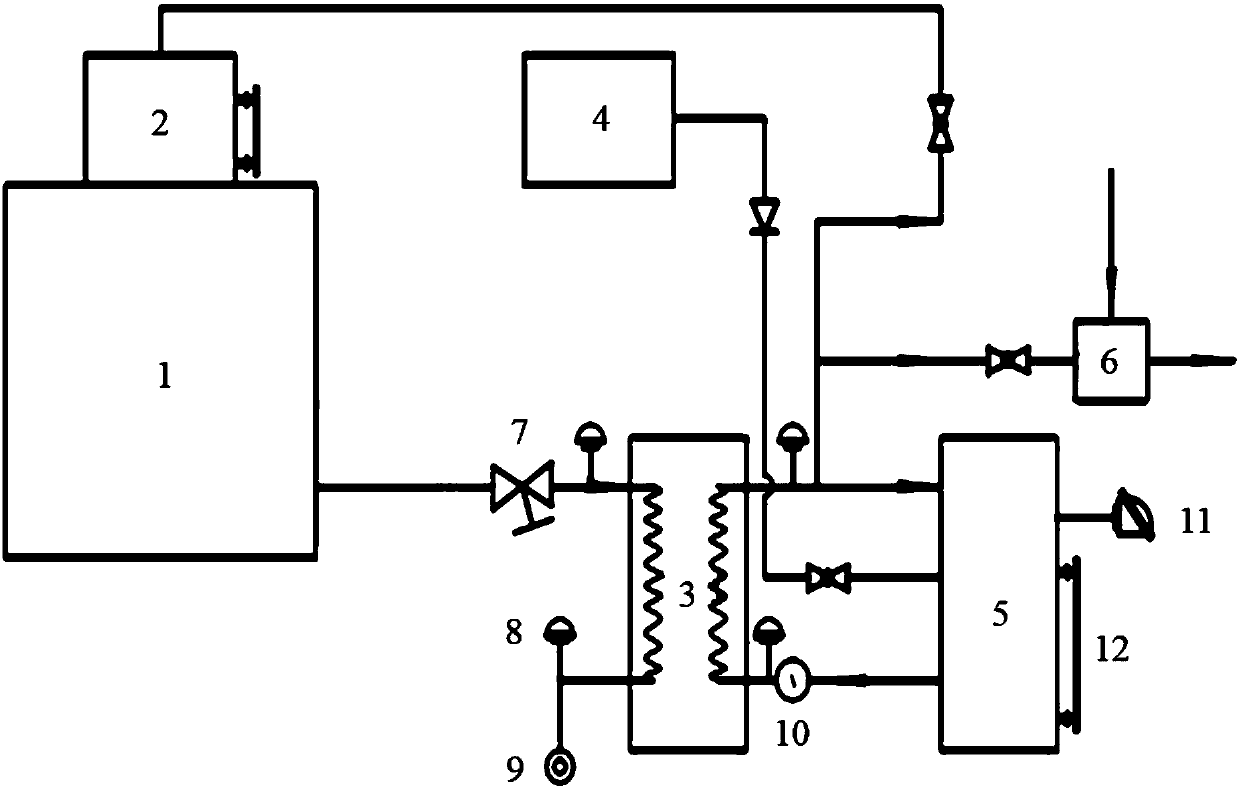

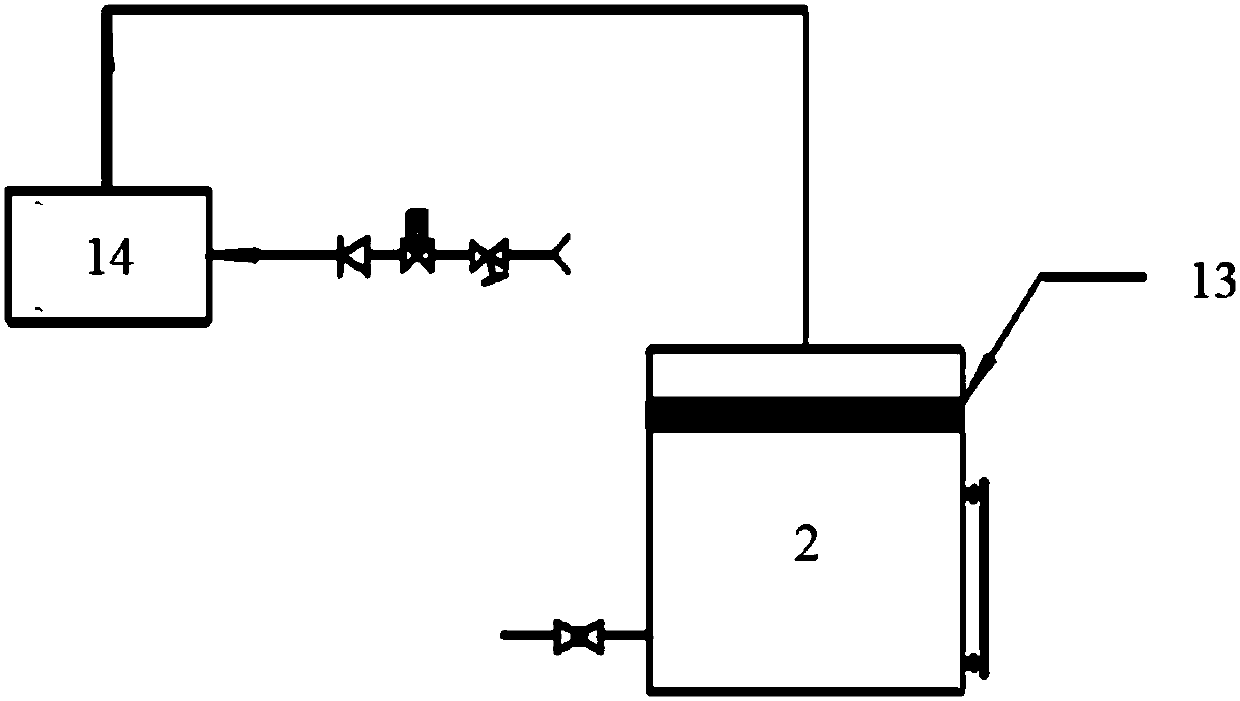

Sterilizer heat recovery system

A sterilizer, heat recovery technology, applied in heating, lighting and heating equipment, steam/steam condensers, etc., can solve problems such as affecting the facility environment and difficulty in discharge, and achieve the effect of improving work efficiency and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

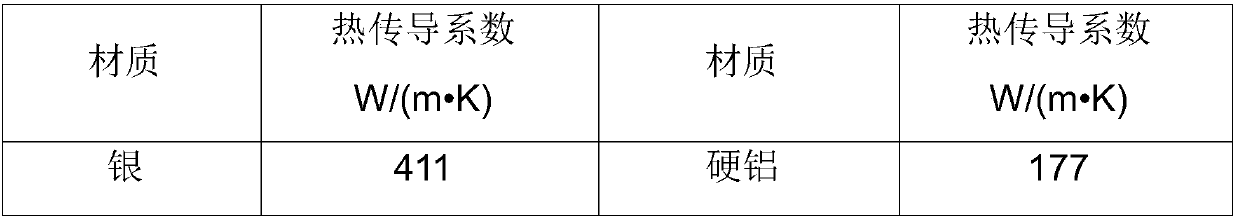

[0066] The raw material formula of the heat insulation layer includes: 25% water-based polyurethane resin, 15% polytetrafluoroethylene, 13% sodium methylene dinaphthalene sulfonate, 5% glycol ether, 3% silicone acrylic emulsion, 7% styrene acrylic emulsion, Silicon carbide 3%, diatomaceous earth 7%, polysiloxane prepolymer 3%, benzophenone 7%, leveling agent 2%, defoamer 2%, dispersant 3%, thickener 2% , Stabilizer 3%. Add the above heat insulation layer raw materials into a strong mixer and stir for 5 minutes to obtain the desired heat insulation layer material.

Embodiment 2

[0068] The raw material formula of the heat insulation layer includes: 30% water-based polyurethane resin, 20% polytetrafluoroethylene, 10% sodium methylene dinaphthalene sulfonate, 8% glycol ether, 5% silicone acrylic emulsion, 5% styrene acrylic emulsion, Silicon carbide 5%, diatomaceous earth 5%, polysiloxane prepolymer 2%, benzophenone 5%, leveling agent 1%, defoamer 1%, dispersant 1%, thickener 1% , Stabilizer 1%. Add the above-mentioned anti-wear layer raw materials into a strong mixer and stir for 8 minutes to obtain the required heat insulation layer material.

[0069] The heat insulation layer materials of Embodiment 1 and Embodiment 2 were attached to the outer layer of the heat preservation water tank 5 respectively, and then the water temperature variation in the heat preservation water tank 5 was measured within 12 hours as shown in Table 3 (under shutdown state).

[0070] 【table 3】

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com