Charging seat

A charging stand and a technology to be charged, which is applied in the direction of current collectors, electric vehicles, electrical components, etc., can solve problems such as inability to charge, coating peeling off, pogo pin corrosion, etc., to avoid long-term exposure, avoid corrosion, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

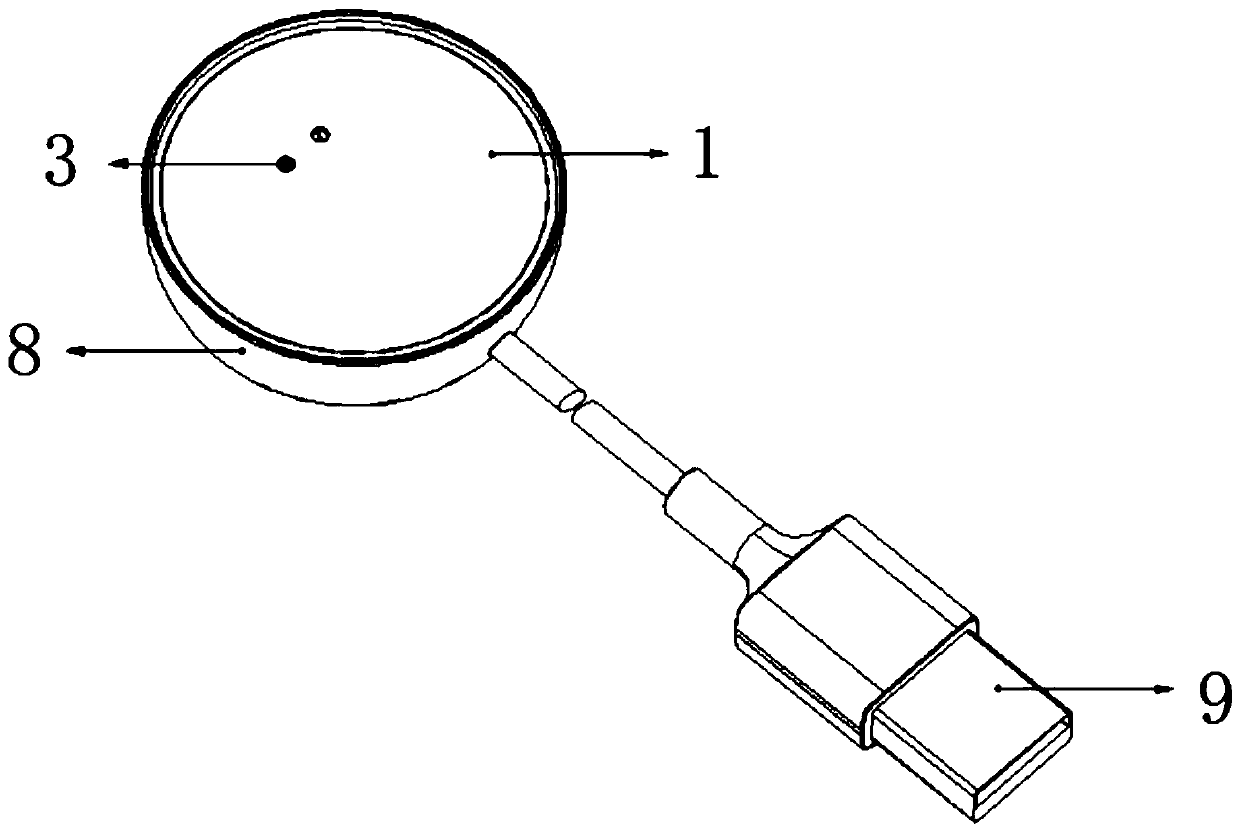

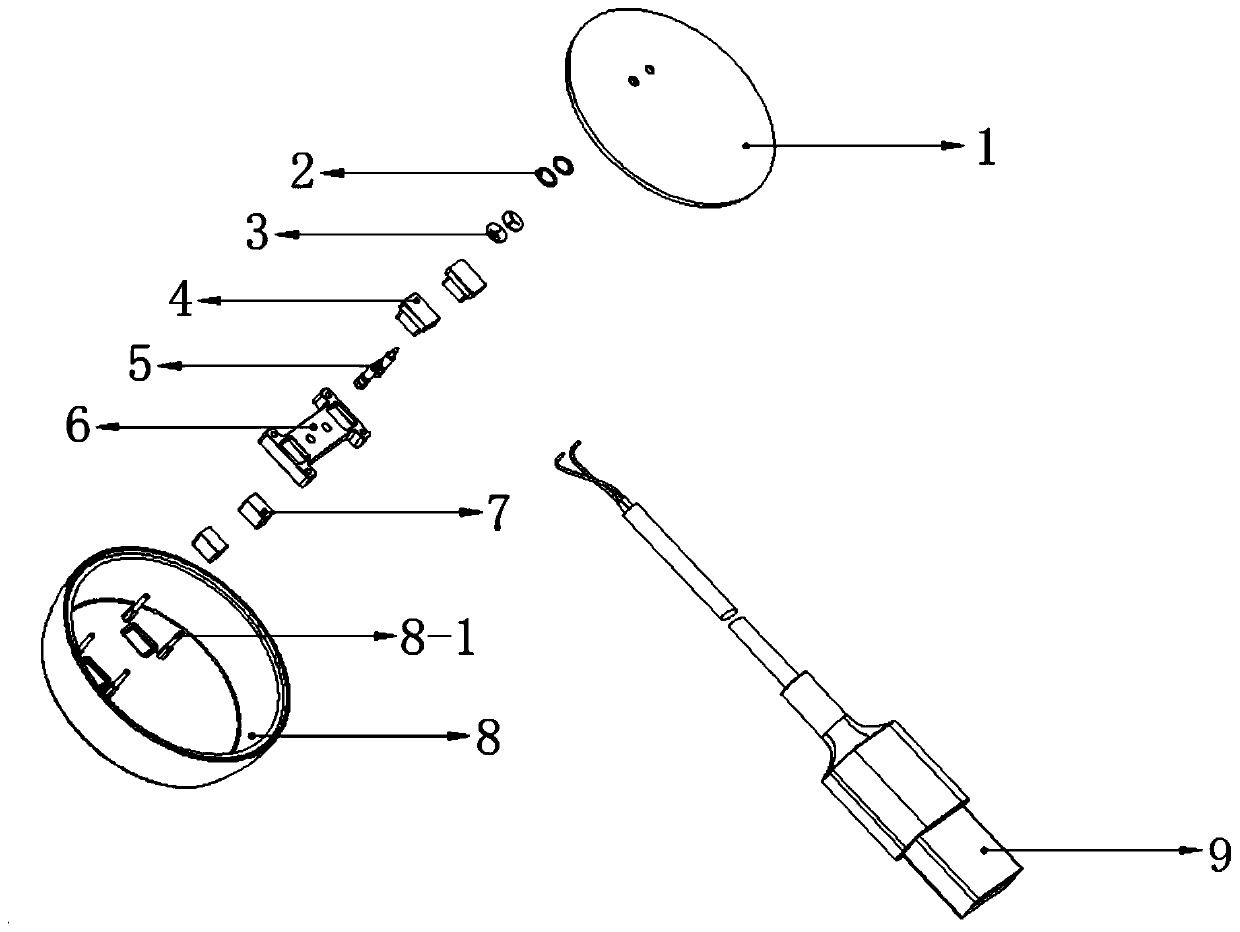

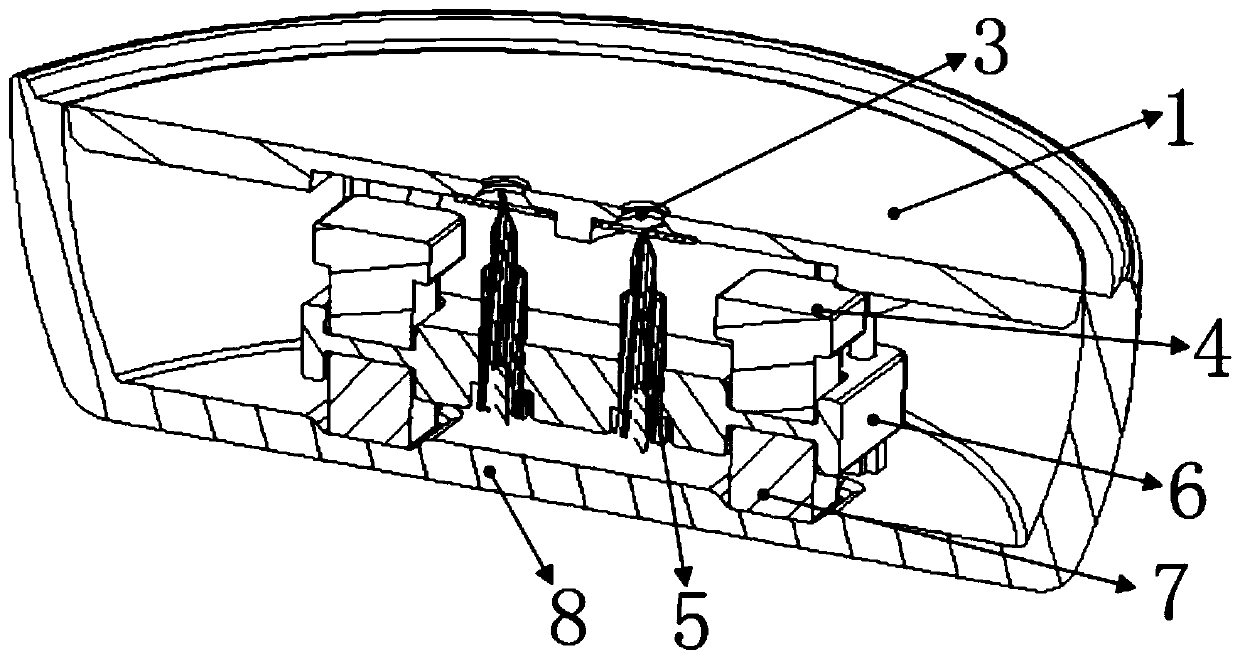

[0031] Such as figure 1 and figure 2 As shown, a charging stand is used in conjunction with a device to be charged with a built-in magnetic attraction. An accommodation cavity is formed, the electrical connector 5 is arranged inside the accommodation cavity, the USB cable passes through the lower case 8 of the charging stand and the electrical connector 5 is welded and assembled to the lower case 8 of the charging stand, and the accommodation cavity also includes a socket for driving the electrical connector 5 from The telescopic part protruding from the upper shell 1 of the charging stand, and the electrical connector 5 are initially fixed in the accommodating cavity. The magnetic parts attract each other and protrude out of the upper shell 1 of the charging stand to realize electrical contact with the charging terminal of the main body of the device to be charged. Wherein, the electrical connector 5 is a pogo pin or a copper pillar.

[0032] Specifically, the telescopic ...

Embodiment 2

[0038] Considering from the perspective of assembly process, the bracket 6 can use a regular-shaped structure, and the bracket 6 is set as a column structure. For this reason, on the basis of Embodiment 1, the following optimal structure of the bracket 6 is given:

[0039] Such as Figure 7 and Figure 8 As shown, the bracket 6 is arranged parallel to the upper shell 1 of the charging base, the middle part of the bracket 6 is fixedly provided with an electrical connector 5, the top surface of the bracket 6 is also provided with a groove structure for fixing the bracket magnet 4, and the bottom of the lower shell 8 of the charging base is in phase with the bracket magnet 4. The lower casing magnet 4 is fixedly arranged at the corresponding position.

[0040]In order to arrange the bracket magnet 4 on the bracket 6 more stably, a groove structure is fixedly arranged on the top surface of the bracket 6, so that the bracket magnet 4 can be stably positioned in the groove of the b...

Embodiment 3

[0046] On the basis of Embodiment 1 and Embodiment 2, in order to realize the fixation of the bracket 6 along the horizontal direction parallel to the upper case 1 of the charging stand, it is necessary to fix the guide part in the accommodating cavity and at the edge of the bracket 6, wherein the guide The structure of the department preferably adopts the following structure:

[0047] Such as Figure 5 and Figure 6 As shown, guide rail 11-1 is selected as guide part, and guide rail 11-1 is arranged on the four corners of bracket 18, and guide rail channel hole 6-1 is set at four corners of bracket 6, and guide rail 11-1 is arranged on guide rail channel hole 6-1 The gap between the inside and the guide rail 11-1 and the guide rail channel hole 6-1 is small enough to realize the sliding fit between the bracket 6 and the guide rail 11-1, and then realize the horizontal direction of the bracket 6 parallel to the upper shell 1 of the charging stand. fixed.

[0048] The specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com