Lead-acid storage battery curved plate gate structure

A lead-acid battery and curved surface technology, applied in the direction of electrode carrier/collector, can solve the problems of poor corrosion resistance, uneven coating, poor bonding force between grid and living matter, etc., to save costs and improve bonding High efficiency, easy to coat evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

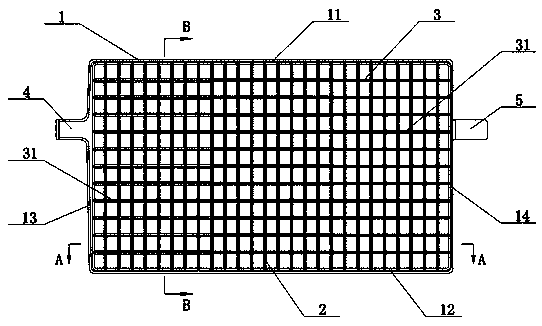

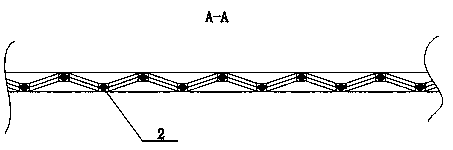

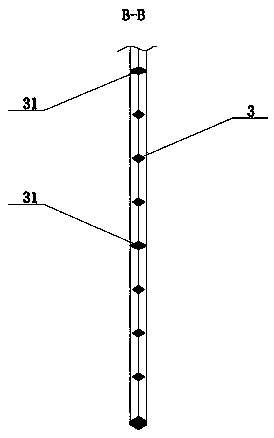

[0017] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a frame 1, vertical ribs 2, horizontal ribs 3, and tabs 4, and the frame 1 includes a first horizontal frame 11, a second horizontal frame 12, a first vertical frame 13. The second longitudinal frame 14, a plurality of vertical ribs 2 are arranged between the first transverse frame 11 and the second transverse frame 12, and a plurality of vertical ribs 2 are arranged between the first longitudinal frame 13 and the second longitudinal frame 14 The horizontal ribs 3, the tabs 4 are arranged on the first longitudinal frame 13, the vertical ribs 2 are staggered on the horizontal ribs 3 in a wave shape, and the horizontal ribs 3 are from the first longitudinal frame 13 to the second longitudinal frame 14. The cross-sectional area gradually decreases, the cross-sectional area of the first longitudinal frame 13 is larger than the cross-sectional area of the second lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com