Lithium battery silicon carbon negative electrode slurry and preparation method thereof, and lithium ion battery

A negative electrode slurry, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slurry settlement and delamination, and achieve the effect of stable surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A lithium battery silicon carbon negative electrode slurry, comprising the following components in parts by mass: 12 parts of silicon carbon; 80 parts of graphite; 2 parts of a first conductive agent; 0.3 parts of a second conductive agent; 5 parts of a binder; 50 parts of water share,

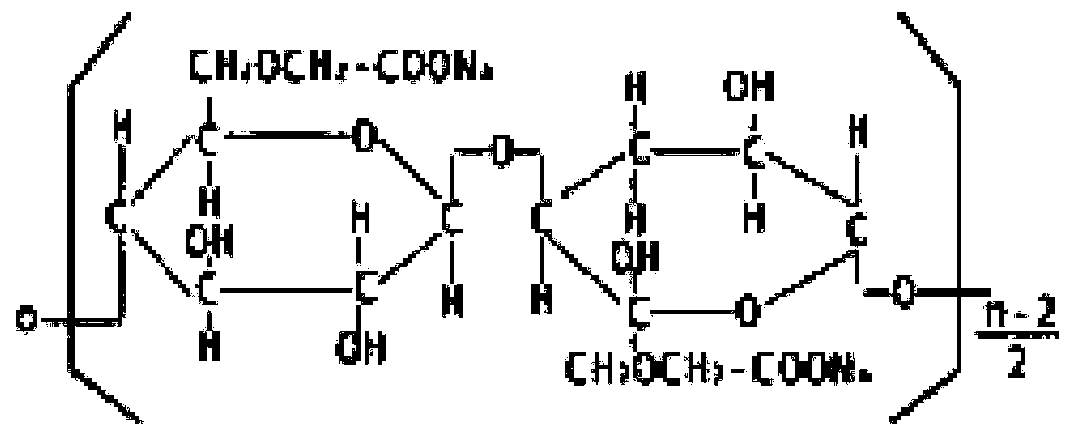

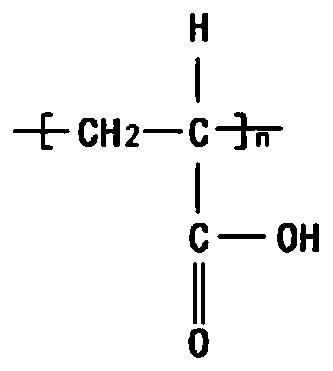

[0040] Wherein, the binder is polyacrylic acid, the first conductive agent is SP, and the second conductive agent is ultralong linear carbon nanotubes, the aspect ratio of the carbon nanotubes is 15,000-30,000, and the diameter is 1-100 nm. The carbon nanotubes are mixed with sodium carboxymethyl cellulose, and the mass ratio of the sodium carboxymethyl cellulose to the carbon nanotubes is 4:100˜5:100.

Embodiment 2

[0042] The preparation method of the lithium battery silicon carbon negative electrode slurry described in embodiment 1 comprises the following steps:

[0043] Step 1: Disperse 2 parts of the first conductive agent, 0.3 parts of the second conductive agent, 2.5 parts of the binder, and 25 parts of water. The dispersion line speed is 15m / s, the dispersion temperature is 25°C, and the dispersion time is 120min. a mixture;

[0044] Step 2: Add 12 parts of silicon carbon to the above first mixture, and disperse, the dispersion line speed is 8m / s, the dispersion temperature is 25°C, and the dispersion time is 30min, to obtain the second mixture;

[0045] Step 3: add 80 parts of graphite to the above second mixture, and disperse, the dispersion line speed is 8m / s, the dispersion temperature is 25°C, and the dispersion time is 120min, to obtain the third mixture;

[0046] Step 4: Add 2.5 parts of binder and 25 parts of water to the above-mentioned third mixture, and disperse, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

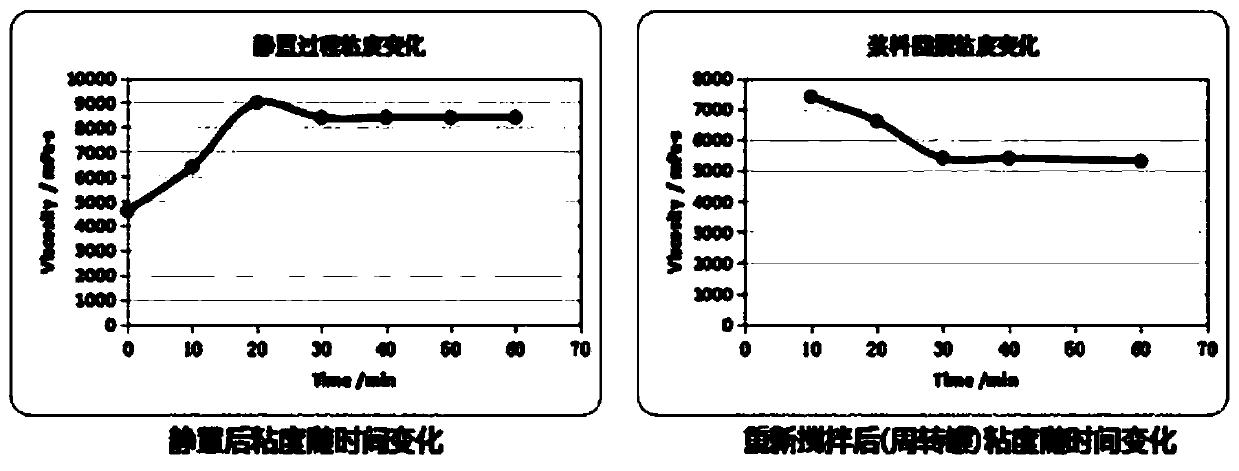

| viscosity | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com