Carbon counter electrode antimony sulfide thin film solar cell and preparation method thereof

A thin-film solar cell and antimony sulfide technology, applied in nano-semiconductor materials and new energy fields, can solve the problems of expensive metal electrodes, affecting long-term operation stability, and being unsuitable for commercial applications, achieving great application value and low equipment requirements. , the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Treatment of FTO conductive film: Clean the FTO conductive glass with glass cleaner, acetone, and isopropanol ultrasonically, dry it with nitrogen, and treat it with UV-ozone for 30 minutes.

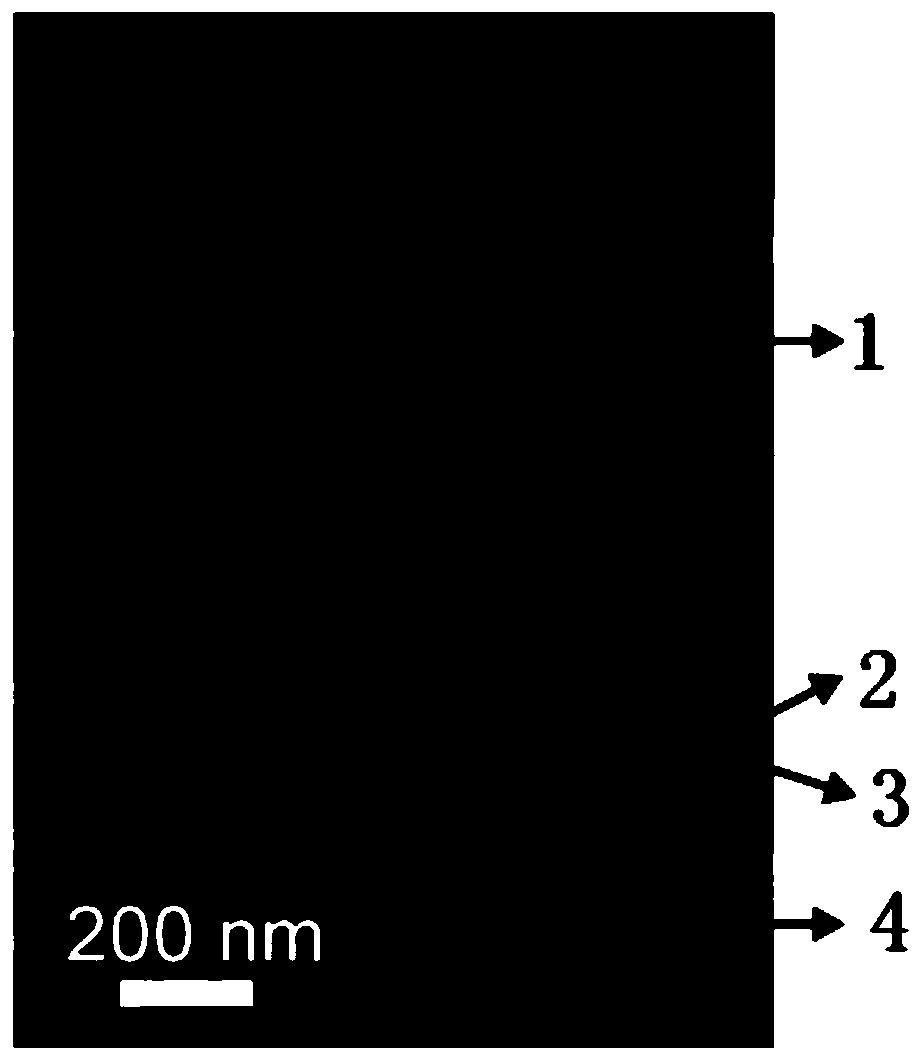

[0029] (2) The preparation steps of the electron transport layer: on the clean FTO conductive substrate by spin-coating TiO 2 The sol-gel precursor was then annealed in air at a temperature of 450 o C, the annealing time is 30 minutes. (The thickness of the titanium dioxide film obtained is 20-40 nm)

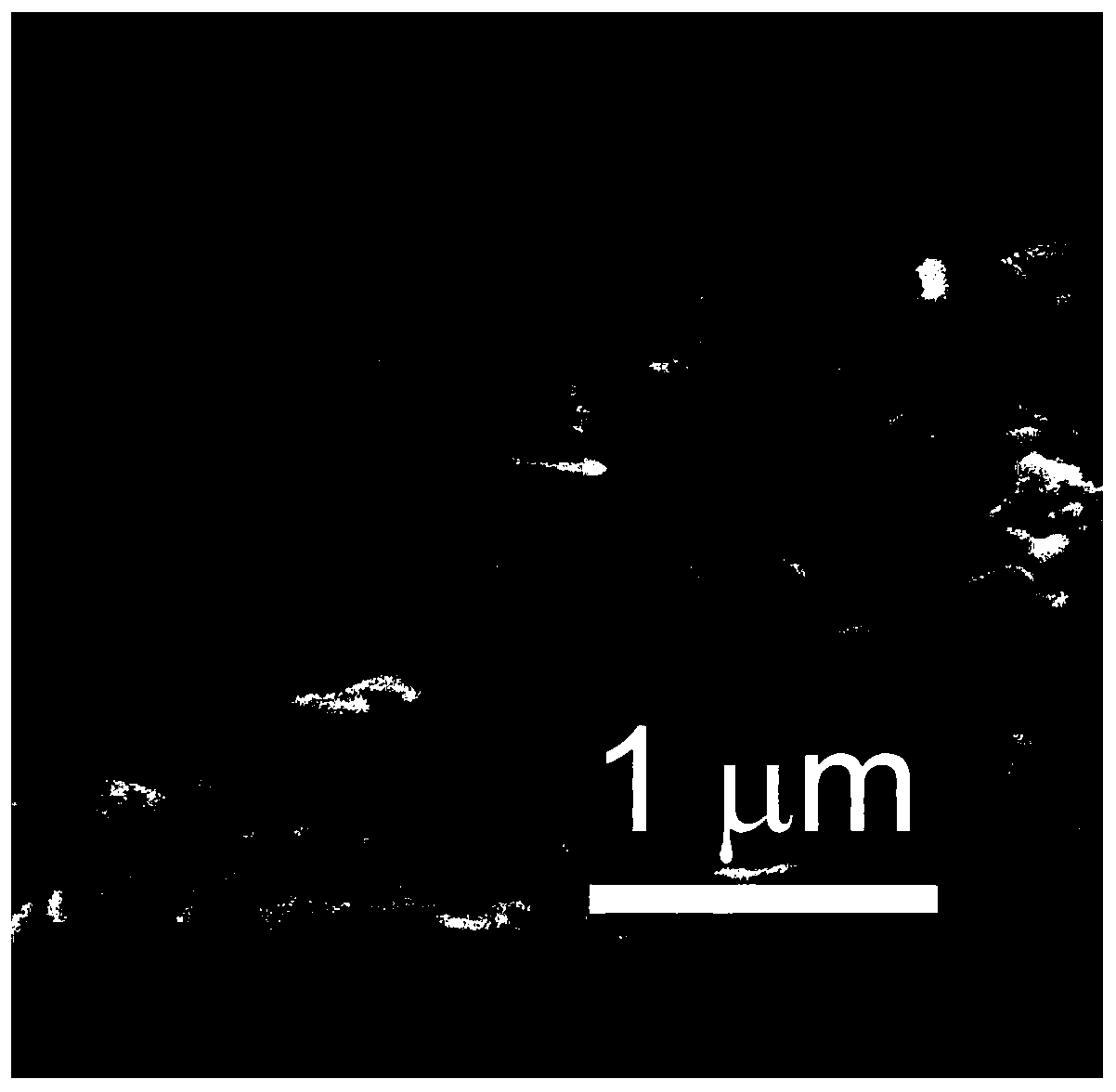

[0030] (3) The preparation steps of antimony sulfide thin film light absorption layer: 360 mL Na with a concentration of 0.25 mol / L 2 S 2 o 3 solution placed in less than 5 o C in an ice bath, then to Na 2 S 2 o 3 Add 40 mL of SbCl with a concentration of 0.07 mol / L dropwise to the solution 3 acetone solution and using a magnetic stirrer to stir, dropwise added SbCl 3 After the acetone solution, when the solution turns orange after 30 minutes of reaction, it will be co...

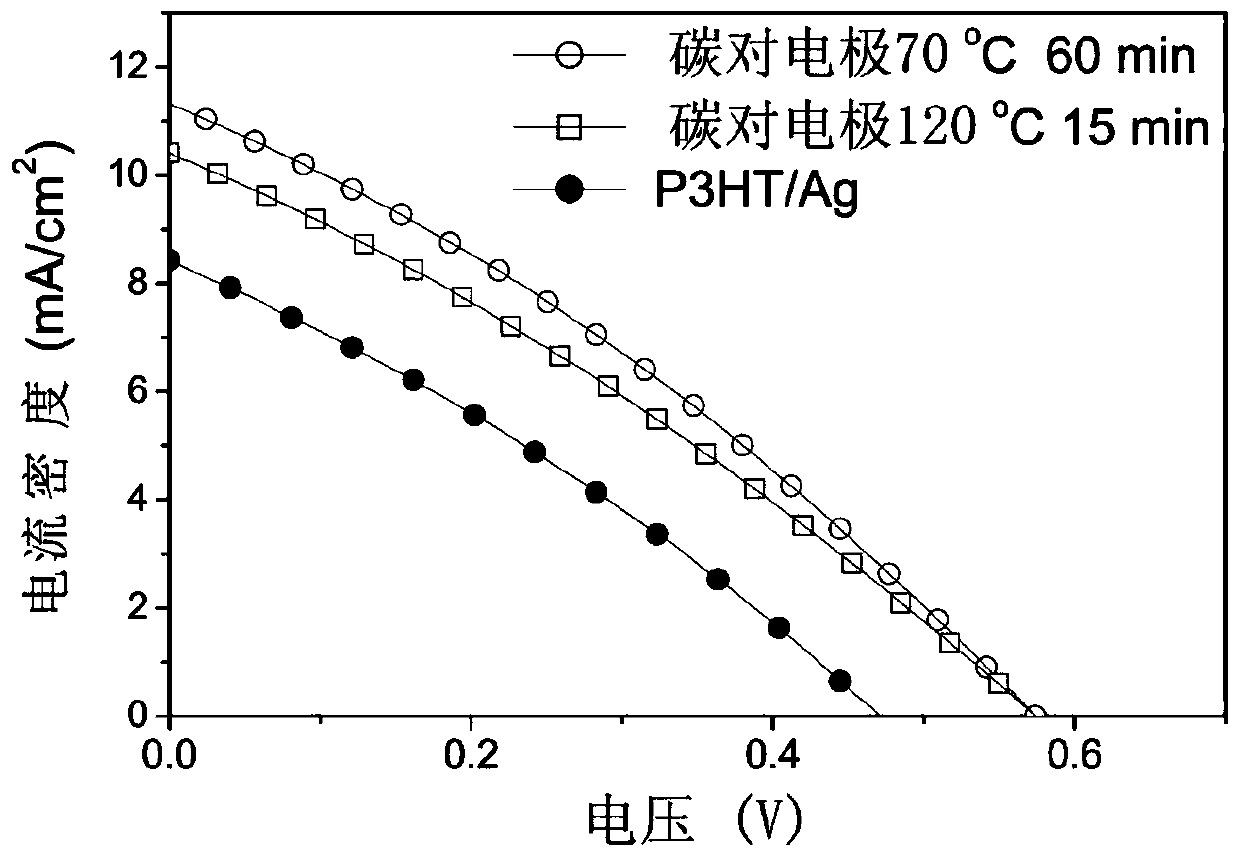

Embodiment 2

[0033] (1) Treatment of FTO conductive film: Clean the FTO conductive glass with glass cleaner, acetone, and isopropanol ultrasonically, dry it with nitrogen, and treat it with UV-ozone for 30 minutes.

[0034](2) The preparation steps of the electron transport layer: on the clean FTO conductive substrate by spin-coating TiO 2 The sol-gel precursor was then annealed in air at a temperature of 450 o C, the annealing time is 30 minutes. (The thickness of the titanium dioxide film obtained is 20-40 nm)

[0035] (3) The preparation steps of antimony sulfide thin film light absorption layer: 360 mL Na with a concentration of 0.25 mol / L 2 S 2 o 3 solution placed in less than 5 o C in an ice bath, then to Na 2 S 2 o 3 Add 40 mL of SbCl with a concentration of 0.07 mol / L dropwise to the solution 3 acetone solution and using a magnetic stirrer to stir, dropwise added SbCl 3 After the acetone solution, when the solution turns orange after 30 minutes of reaction, it will be coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com