Sizing agent for silicon carbide or silicon nitride fibers and preparing method and application of sizing agent

A technology of silicon nitride fiber and silicon carbide fiber, which is applied in fiber processing, textile and papermaking, etc., can solve the problems of easy fluffing and broken ends, and achieve the effect of improving strength, stable performance, simple process and equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A sizing agent for silicon carbide or silicon nitride fiber provided by the invention consists of 0.2 parts by weight of polyvinyl alcohol, 0.1 part of modified silicone oil, 0.5 part of alkylphenol polyoxyethylene ether, 0.1 part of benzoic acid, deionized 100 parts of water.

[0026] The polyvinyl alcohol is PVA17-88, that is, polyvinyl alcohol with a surface polymerization degree of 1700 and an alcoholysis degree of 88%. Effective substance for sizing agent.

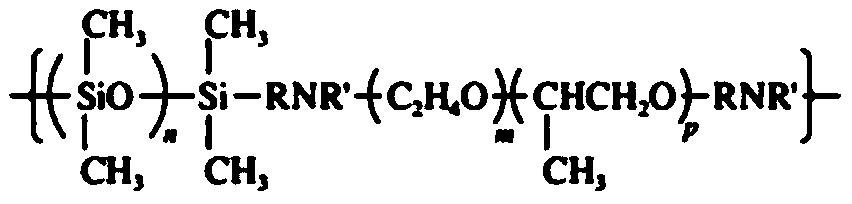

[0027] The modified silicone oil is polyether amino block modified silicone oil. Polyether amino block modified silicone oil is the fourth generation (latest generation) softener, which is more hydrophilic than other conventional modified silicone oils, and endows fibers or fabrics with certain antistatic properties, reducing the absorption of water molecules and dust by fibers. At the same time, emulsifiers can be reduced or eliminated. Typical molecular structure of polyether amino block modified silicone ...

Embodiment 2

[0039] A sizing agent for silicon carbide or silicon nitride fibers provided by the invention consists of 0.8 parts by weight of polyvinyl alcohol, 1.5 parts of modified silicone oil, 3.5 parts of alkylphenol polyoxyethylene ether, 0.25 parts of benzoic acid, deionized 100 parts of water.

[0040] The polyvinyl alcohol is PVA17-88, that is, polyvinyl alcohol with a surface polymerization degree of 1700 and an alcoholysis degree of 88%. Effective substance for sizing agent.

[0041] The modified silicone oil is polyether amino block modified silicone oil. Polyether amino block modified silicone oil is the fourth generation (latest generation) softener, which is more hydrophilic than other conventional modified silicone oils, and endows fibers or fabrics with certain antistatic properties, reducing the absorption of water molecules and dust by fibers. At the same time, emulsifiers can be reduced or eliminated. Typical molecular structure of polyether amino block modified sili...

Embodiment 3

[0053] A sizing agent for silicon carbide or silicon nitride fibers provided by the invention consists of 0.3 parts by weight of polyvinyl alcohol, 0.2 parts of modified silicone oil, 1.0 parts of alkylphenol polyoxyethylene ether, 0.13 parts of benzoic acid, deionized 100 parts of water.

[0054] The polyvinyl alcohol is PVA17-88, that is, polyvinyl alcohol with a surface polymerization degree of 1700 and an alcoholysis degree of 88%. Effective substance for sizing agent.

[0055] The modified silicone oil is polyether amino block modified silicone oil. Polyether amino block modified silicone oil is the fourth generation (latest generation) softener, which is more hydrophilic than other conventional modified silicone oils, and endows fibers or fabrics with certain antistatic properties, reducing the absorption of water molecules and dust by fibers. At the same time, emulsifiers can be reduced or eliminated. Typical molecular structure of polyether amino block modified sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com