A kind of ultra-high melt strength blow molding resin composition and preparation method thereof

A resin composition and melt strength technology, applied in the field of ultra-high melt strength blow molding resin composition and its preparation, can solve the problems of loss of high gloss, low melt strength, and unsuitable blow molding process, etc.

Active Publication Date: 2021-05-18

SHANGHAI KUMHO SUNNY PLASTICS

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Cross-linking PMMA can increase the melt strength of PMMA / ASA resins, but paradoxically, the occurrence of cross-linking will cause PMMA / ASA resins to lose their high gloss, piano black effect, such materials cannot replace piano black paint Effect

[0004] Many patents such as CN106046643B, CN107841077A and CN 107501829 A report the preparation method of injection molding grade PMMA / ASA resin. These PMMA / ASA resins have good fluidity and low melt strength in order to form large parts, so they are not applicable in blow molding

About ultra-high melt strength blow molding grade PMMA / ASA resin composition and preparation method thereof, there is no report yet

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Login to View More

Abstract

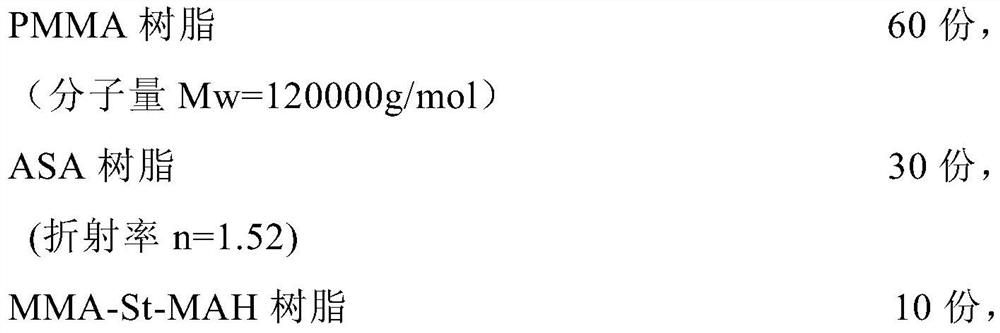

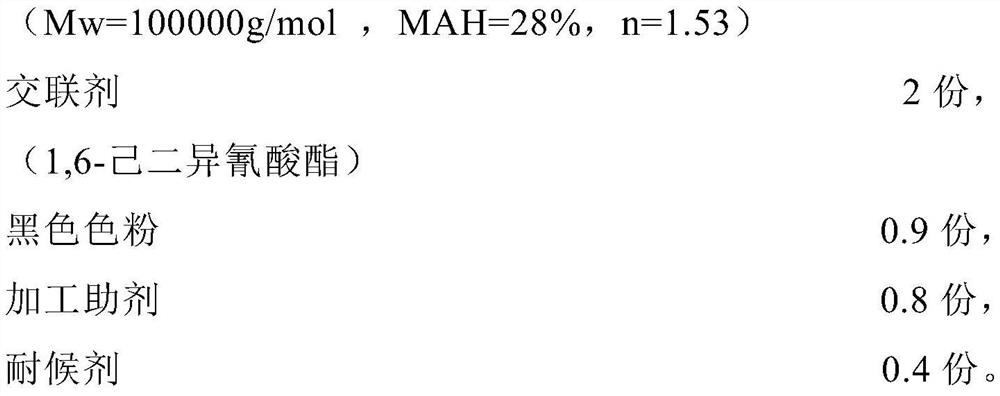

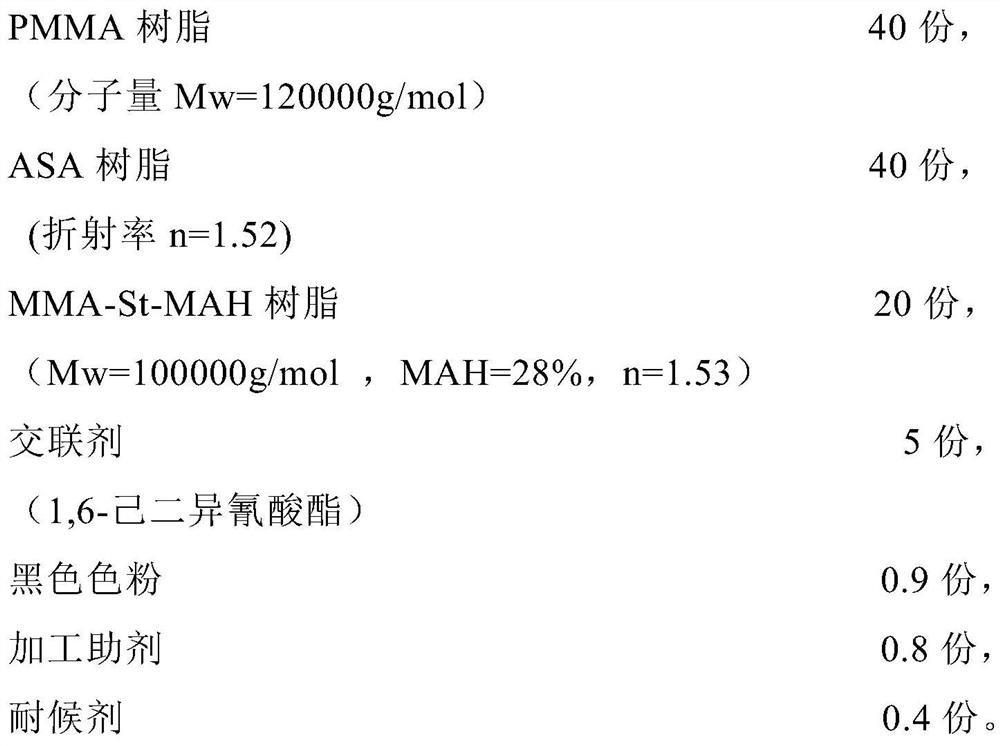

The invention relates to an ultra-high melt strength blow molding resin composition and a preparation method thereof, which is prepared by using the following components and raw materials in parts by weight: PMMA resin 40-60, ASA resin 30-40, MMA-St-MAH Copolymer resin 10‑20, crosslinking agent 1‑5, black toner 0.3‑1.0, processing aid 0.6‑1.5, weather resistance agent 0.3‑1.5, premix the above raw materials in a high-speed mixer for 3‑10 minutes, and then premix A PMMA / ASA resin composition with ultra-high melt strength can be obtained. Compared with the prior art, the present invention has the advantages of ultra-high melt strength, excellent comprehensive performance, etc., and also has the appearance effect of piano black and excellent weather resistance and scratch resistance performance, and is very suitable for blow molding spray-free high-gloss pianos Black car tail, spoiler and other parts.

Description

technical field [0001] The invention relates to the technical field of polymer material processing, in particular to an ultra-high melt strength blow molding resin composition and a preparation method thereof. Background technique [0002] Automobile rear fins and spoilers are usually prepared by blow molding. The material used for blow molding is mainly ABS resin. In addition to good mechanical properties, it also requires high melt strength and heat resistance. However, ABS is The weather resistance cannot meet the requirements of automotive exterior decoration, so it is necessary to make up for the weather resistance of ABS through the method of painting in the second process. However, the painting process is complicated, low in efficiency, high in cost, and causes great environmental pollution. [0003] PMMA / ASA resin has excellent impact resistance, weather resistance and excellent coloring performance, and various colors can be obtained by adding different toners. Be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L33/12C08L51/04C08K5/29

Inventor 查超周霆辛敏琦

Owner SHANGHAI KUMHO SUNNY PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com