Printable plastic film and preparation method thereof

A technology for plastic films and raw materials, applied in the field of printable plastic films and their preparation, can solve the problems of high preparation cost of printable films, difficult preparation of film materials, and high preparation costs, and achieves enhanced printing effect, good adhesion, and improved The effect of the degree of binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

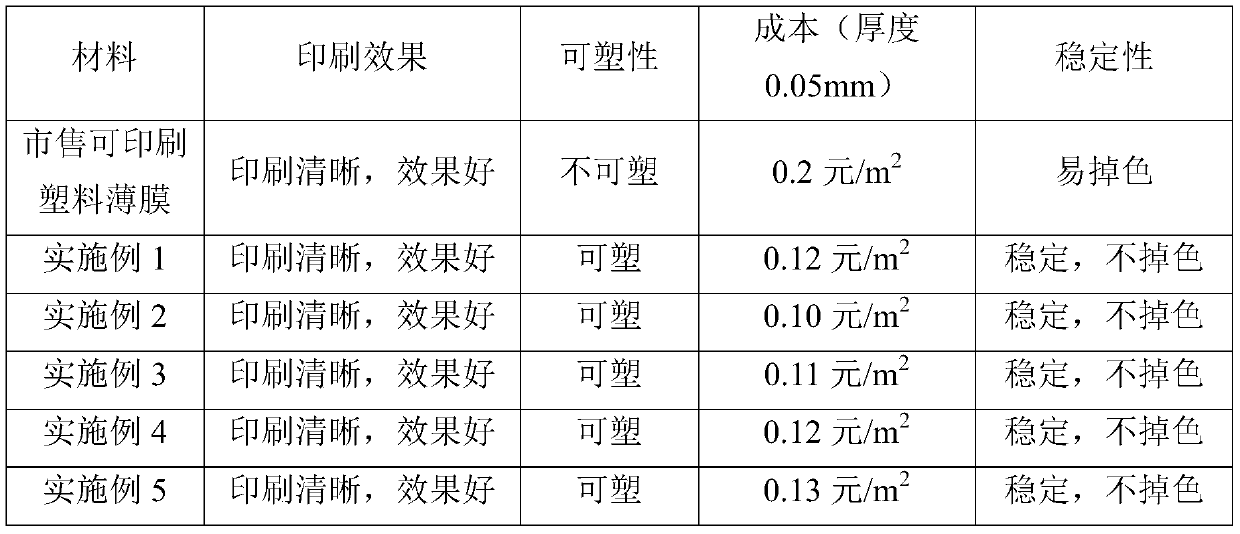

Examples

Embodiment 1

[0026] A printable plastic film

[0027] The raw materials of the printable plastic film include by weight percentage: 90% resin material, 7% conductive material and 3% oily material; the raw materials for preparing the resin material include: polyethylene 75%, C5 petroleum resin 25% ; The raw materials for preparing the conductive material include: 15% of carbon black, 20% of graphite, 20% of ferric oxide, 20% of carbon nanotubes and 25% of metal powder.

[0028] Prepared by:

[0029] Step 1, put the resin material into the mixer according to the above weight percentage, heat up to 110°C and stir and mix for 20 minutes;

[0030] Step II, continue to add carbon black, graphite, ferric oxide, carbon nanotubes and metal powder into the mixer according to the above weight percentage, stir and mix for 8 minutes, add the oily material in the above weight percentage, stir and mix evenly;

[0031] In step III, the mixture obtained in step II is transported to the extruder, cast and...

Embodiment 2

[0033] A printable plastic film

[0034] The raw materials of the printable plastic film include by weight percentage: 85% resin material, 10% conductive material and 5% oily material; the raw materials for preparing the resin material include: polyethylene 70%, C5 petroleum resin 30% ; The raw materials for preparing the conductive material include: 10% carbon black, 25% graphite, 15% ferric oxide, 25% carbon nanotube and 25% metal powder.

[0035] Prepared by:

[0036] Step I, put the resin material into the mixer according to the above weight percentage, heat up to 95°C and stir and mix for 25 minutes;

[0037] Step II, continue to add carbon black, graphite, ferric oxide, carbon nanotubes and metal powder into the mixer according to the above weight percentage, stir and mix for 10 minutes, add the oily material in the above weight percentage, stir and mix evenly;

[0038] In step III, the mixture obtained in step II is transported to the extruder, cast and extruded throu...

Embodiment 3

[0040] A printable plastic film

[0041] The raw materials of the printable plastic film include by weight percentage: 95% resin material, 3% conductive material and 2% oily material; the raw materials for preparing the resin material include: polyethylene 80%, C5 petroleum resin 20% ; The raw materials for preparing the conductive material include: 20% of carbon black, 15% of graphite, 25% of ferric oxide, 20% of carbon nanotubes and 20% of metal powder.

[0042] Prepared by:

[0043] Step 1, put the resin material into the mixer according to the above weight percentage, heat up to 120°C and stir and mix for 15 minutes;

[0044] Step II, continue to add carbon black, graphite, ferric oxide, carbon nanotubes and metal powder into the mixer according to the above weight percentage, stir and mix for 5 minutes, add the oily material in the above weight percentage, stir and mix evenly;

[0045] In step III, the mixture obtained in step II is transported to the extruder, cast and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com