Preparation method of polybutyrolactam through anionic ring-opening polymerization

A polybutyrolactam and anion ring-opening technology, which is applied in the field of nylon synthesis technology, can solve the problems of failing to meet the application requirements, small molecular weight of the polymer, clogged pipes, etc. The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

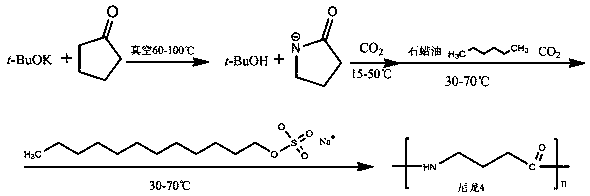

Image

Examples

Embodiment 1

[0048] The present embodiment provides a ring-opening polymerization method for synthesizing polybutyrolactam, and the specific steps are as follows:

[0049] (1) Potassium tert-butoxide activation

[0050] Add 30g of 2-pyrrolidone into a 250ml three-necked flask filled with nitrogen, stirring at a rate of 150r / min, turn off the nitrogen, vacuumize and heat to 80°C for 3 hours; turn off the vacuum and fill with nitrogen, and add 5g of t- Potassium butoxide, turn off the nitrogen again, vacuumize, and keep warm at 80°C for 2h, this is the activation solution.

[0051] (2) Initiated by carbon dioxide

[0052] Take another 500ml three-neck flask, add half of the above activation solution after feeding nitrogen gas, close the nitrogen gas and seal it well, heat it to 40°C and feed dry carbon dioxide gas, set the flow rate to 2.5L / min, feed it for 15 minutes, and stir at It is 180r / min.

[0053] (3) Add paraffin oil and sodium lauryl sulfate

[0054] Turn on the nitrogen gas ag...

Embodiment 2

[0058] This example continues to provide a kind of anionic ring-opening polymerization method synthetic polybutyrolactam, and the steps are as follows:

[0059] (1) Potassium tert-butoxide activation

[0060] Add 30 g of 2-pyrrolidone into a 250 ml three-necked flask filled with nitrogen. The stirring rate was 150r / min, the nitrogen gas was turned off, the vacuum was pumped, and the mixture was heated to 90°C for 2h. After closing the vacuum, fill with nitrogen, and add 5g of potassium tert-butoxide under the protection of nitrogen. Turn off the nitrogen gas again, evacuate, and keep warm at 90°C for 3 hours. This is the activation solution.

[0061] (2) Initiated by carbon dioxide

[0062] Take another 500ml three-necked flask, add half of the above activation solution after feeding nitrogen, close the nitrogen and seal it well, heat it to 50°C and feed dry carbon dioxide gas, set the flow rate to 3L / min, and the carbon dioxide feeding time is 10 minutes, The stirring rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com