A kind of high frequency manganese zinc soft magnetic ferrite material and its preparation method and application

A technology of manganese-zinc soft magnets and soft ferrites, which is applied in the manufacture of inductors/transformers/magnets, inorganic material magnetism, electrical components, etc. problem, to achieve the effect of improving saturation magnetic flux density, high saturation magnetic flux density, and reducing functional loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

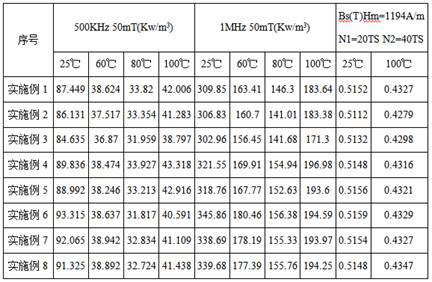

Examples

Embodiment 1

[0033] A high-frequency magnetic core material, the raw material includes a main component and a sub-component, wherein the main component includes the following molar percentage components: Fe 2 O 3 52%, MnO 43%, ZnO 4%, NiO 1.0%, the mass percentage of auxiliary components is: Ca 2 CO 3 0.08%, V 2 O 5 0.01%, Nb 2 O 5 0.01%, K 2 CO 3 0.02%, Co 2 O 3 0.1%, SnO 2 0.01%, the mass percentage of its subsidiary components is the percentage relative to the total mass of the main component.

Embodiment 2

[0035] A high-frequency magnetic core material, the raw material includes a main component and a sub-component, wherein the main component includes the following molar percentage components: Fe 2 O 3 54%, MnO 42.5%, ZnO 3%, NiO 0.5%, the mass percentage of the auxiliary components is: Ca 2 CO 3 0.2%, V 2 O 5 0.06%, Nb 2 O 5 0.05%, K 2 CO 3 0.3%, Co 2 O 3 0.3%, SnO 2 0.06%, the mass percentage of its subsidiary components is the percentage relative to the total mass of the main component.

Embodiment 3

[0037] A high-frequency magnetic core material, the raw material includes a main component and a sub-component, wherein the main component includes the following molar percentage components: Fe 2 O 3 52%, MnO 44%, ZnO 3%, NiO 1.0%, the mass percentage of auxiliary components is: Ca 2 CO 3 0.08%, V 2 O 5 0.01%, Nb 2 O 5 0.01%, K 2 CO 3 0.02%, Co 2 O 3 0.1%, SnO 2 0.01%, the mass percentage of its subsidiary components is the percentage relative to the total mass of the main component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com