Surface with self-lubrication function and preparation method of surface

A self-wetting and functional technology, applied in the surface field with self-wetting function, can solve the problems of complex preparation methods, short transportation distance, slow transportation speed, etc., and achieve simple process, fast flow speed and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

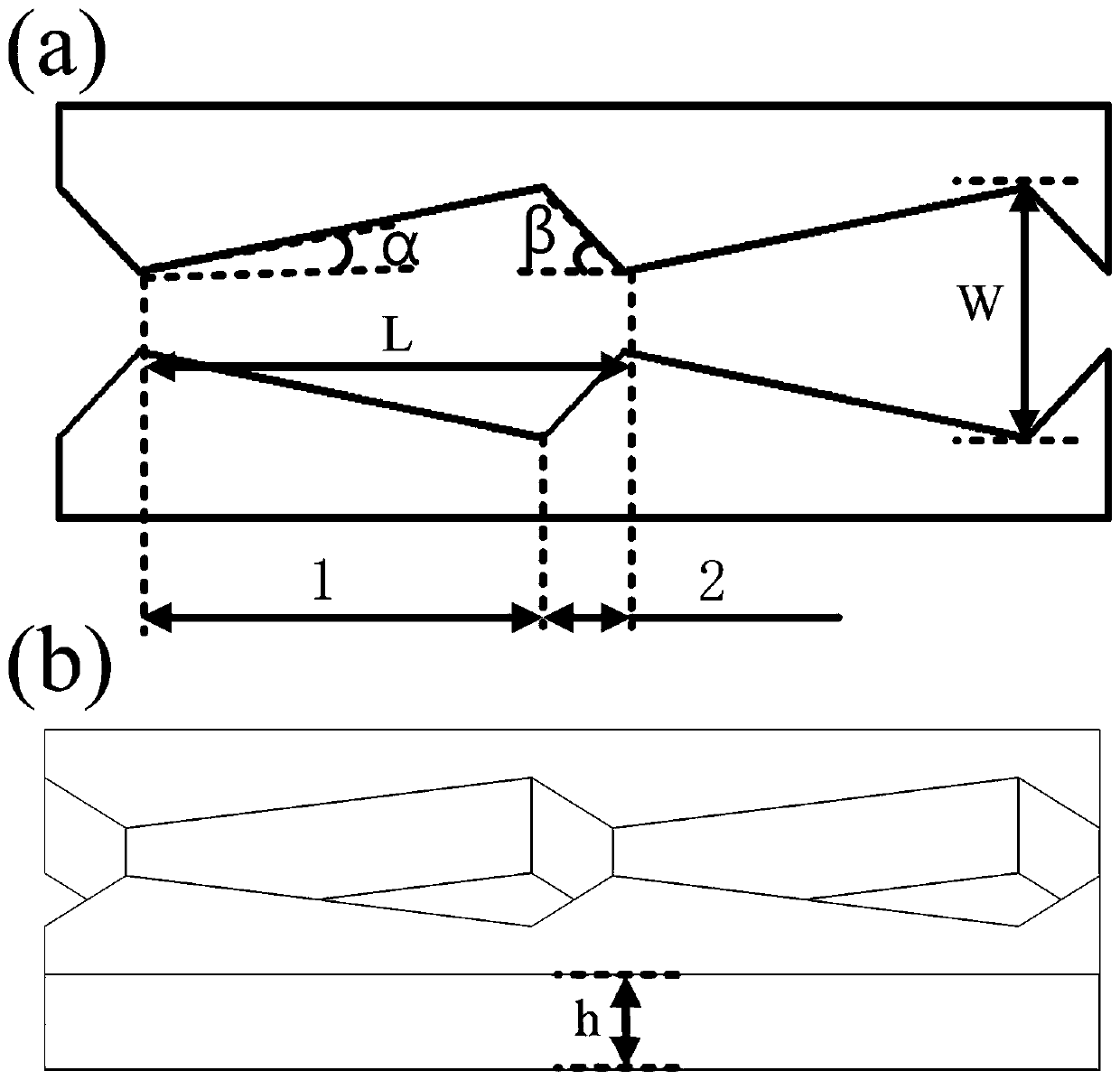

[0031] The design and preparation method of the self-wetting shuttle structure described in this embodiment comprises the following steps:

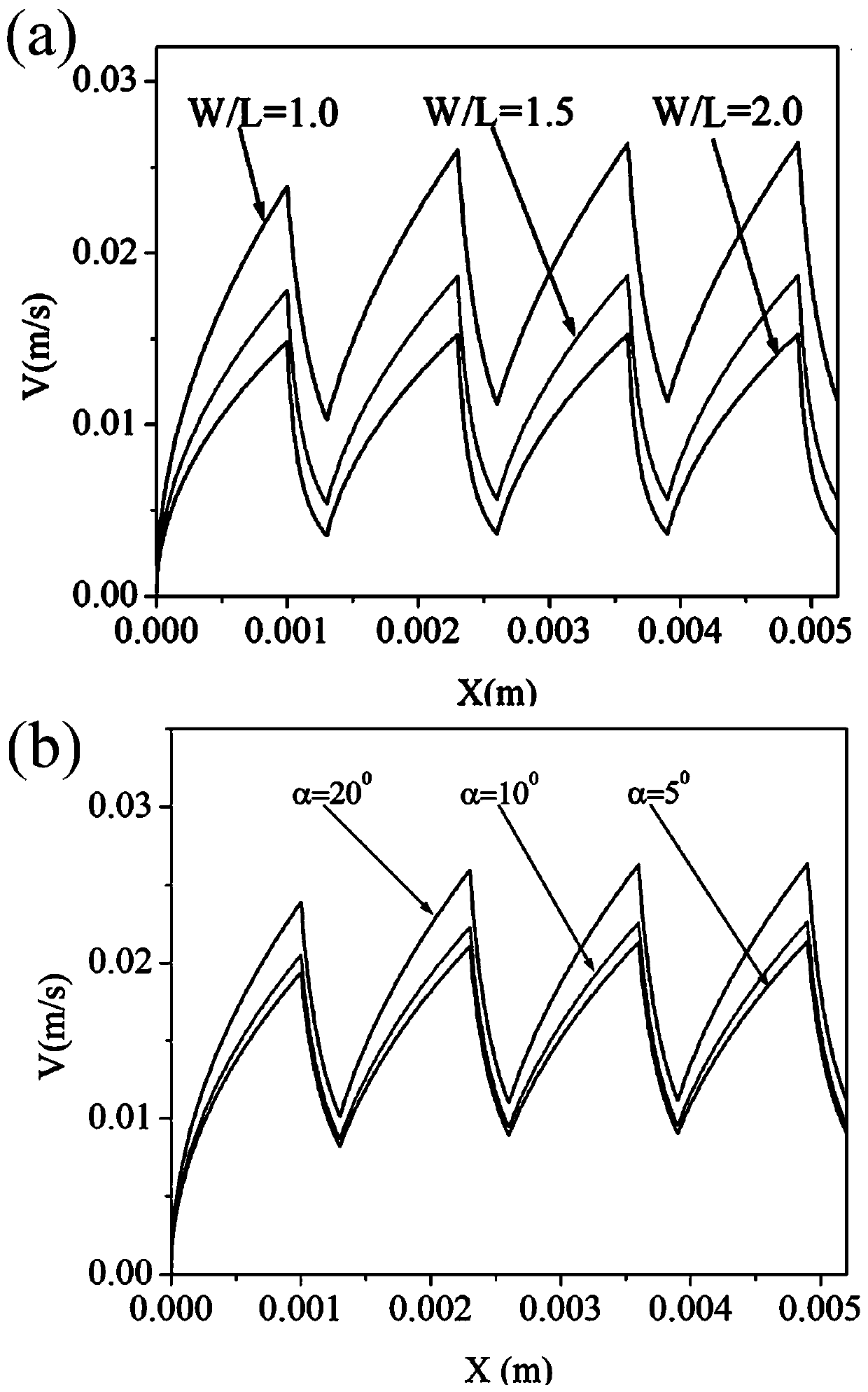

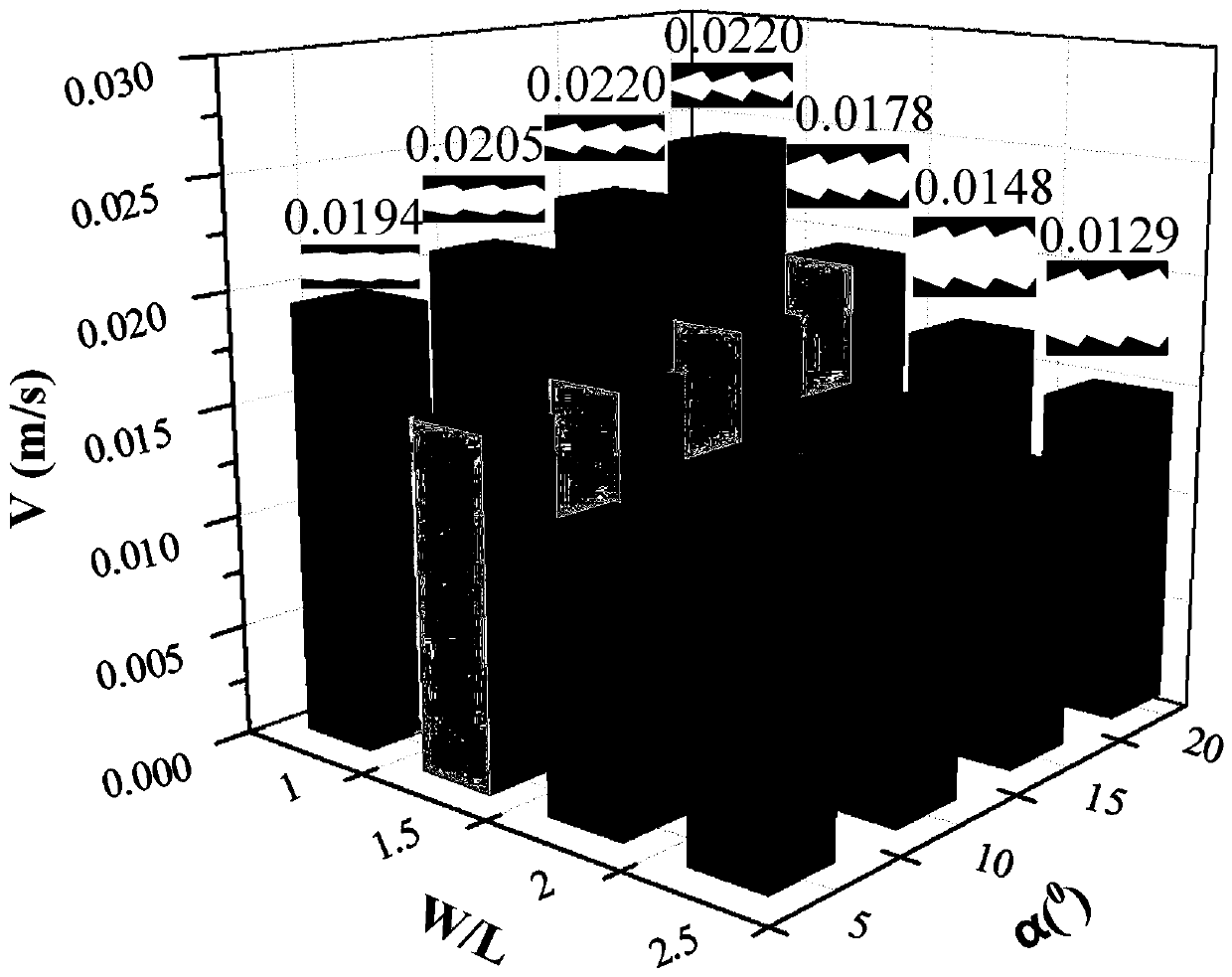

[0032] 1) Establish the transport mechanism formula of the shuttle array structure, study the transport mechanism of various self-propelled microstructures in the past, and expand to the shuttle array microstructure according to the existing theoretical formula. The relationship between liquid displacement distance and velocity is obtained by using liquid surface energy and Laplace force; by studying the relationship between liquid wetting and liquid surface energy, a cone formula for liquid transport in a shuttle array is established. During liquid flow, the potential energy of the system is expressed as:

[0033] U=γ LV ·cosθ·(S 1 +S 2 )-γ LV ·S 3 (1)

[0034] where U is the potential energy of the system in the process of liquid diffusion, S 1 is the area of the two walls of the channel, S 2 is the area of the channel bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com