Strip-steel-plate continuous punching machine

A punching machine and steel plate technology, applied in the field of stamping, can solve the problems of increasing the labor intensity of the staff, increasing safety hazards, deformation of the mounting seat, etc., achieving compact and exquisite overall layout, reducing floor space, and avoiding sliding contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

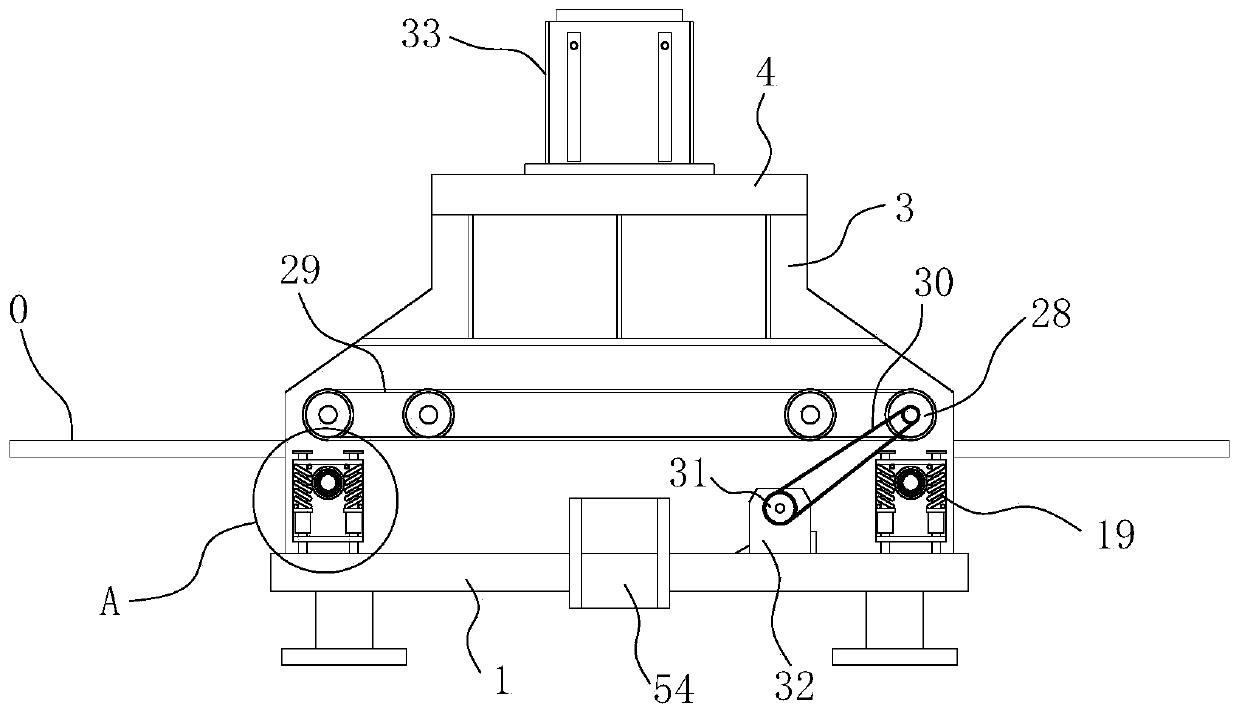

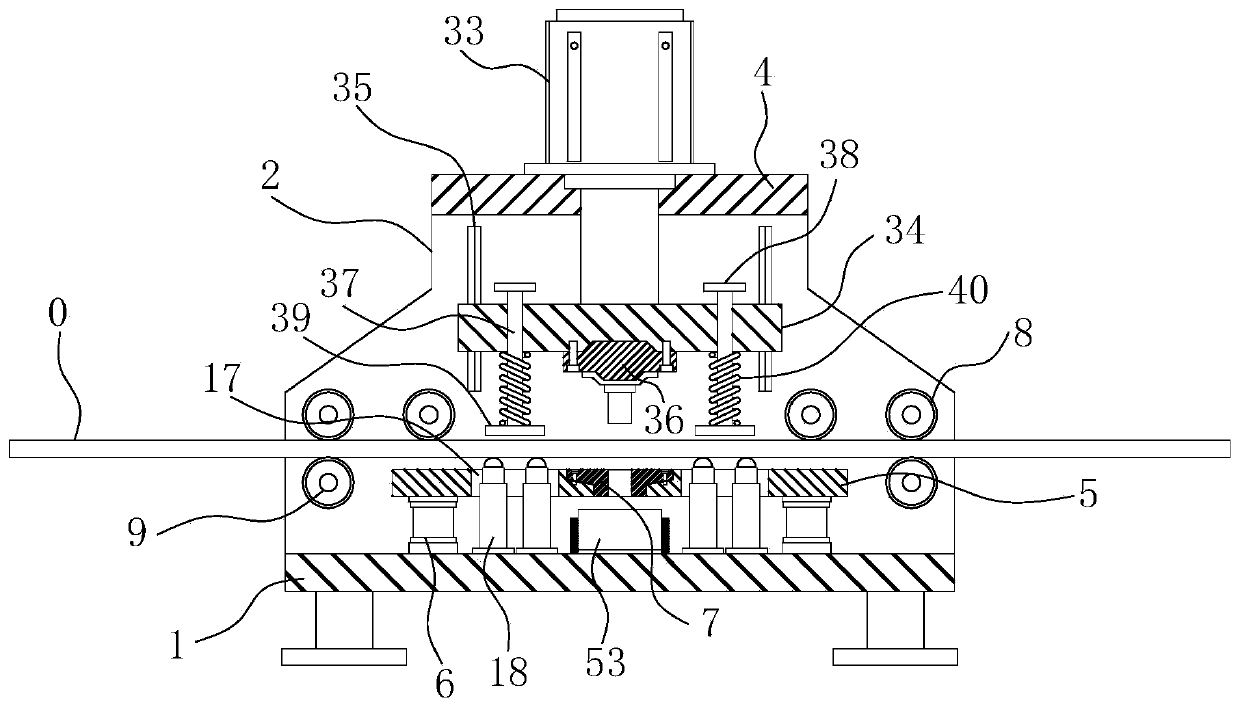

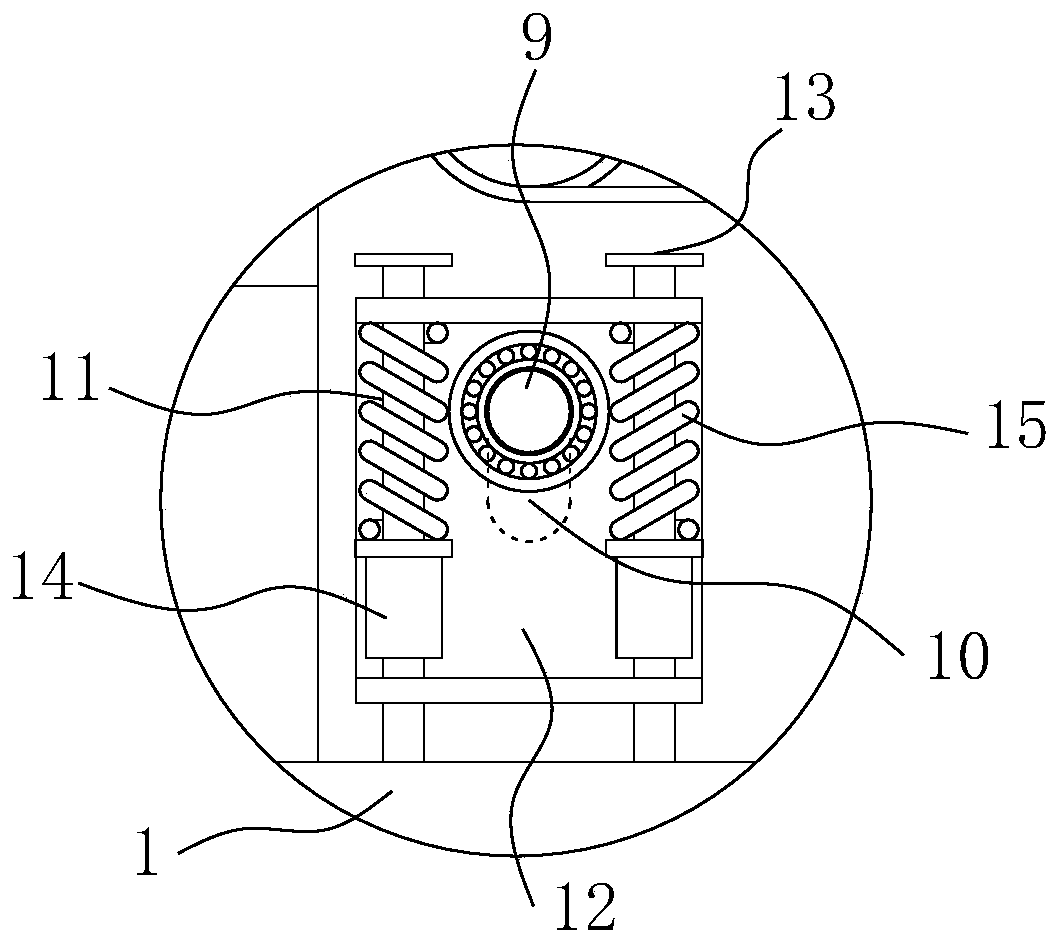

[0030] combine Figure 1-8 Shown a kind of continuous punching machine of strip steel plate, the same as traditional punching machine, the present invention mainly is made of three major parts, comprises frame, conveying device and stamping device. The frame is used to install the sub-parts of the present invention, the conveying device is used to convey the workpiece, and the stamping device cooperates with the conveying device to punch the workpiece during the conveying process. Of course, usually the present invention can also include an industrial computer for overall control of the punching frequency, conveying speed, etc. of the punching machine. Since the industrial computer of the punching machine is a relatively mature product on the market at present, the present invention no longer deals with this issue. For a detailed introduction, the designer can choose a suitable industrial computer, that is, a control system, according to actual needs.

[0031] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com