Fan coil magnetic machine and fan coil magnetic assembly method thereof

A fan and magnetic machine technology, applied in the field of magnetic winding machines, can solve the problems of difficult to effectively control and improve product quality stability, difficult product quality, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

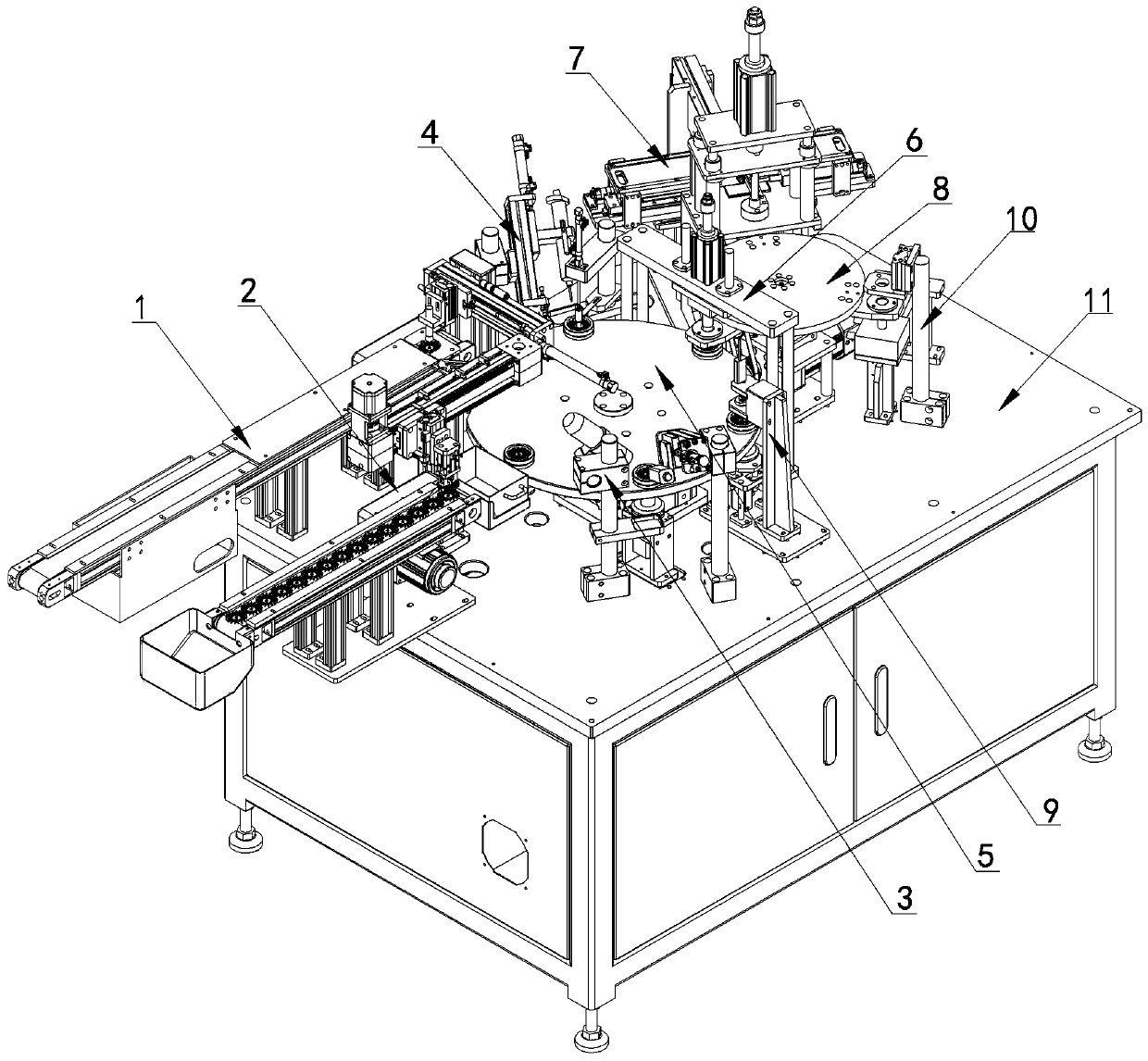

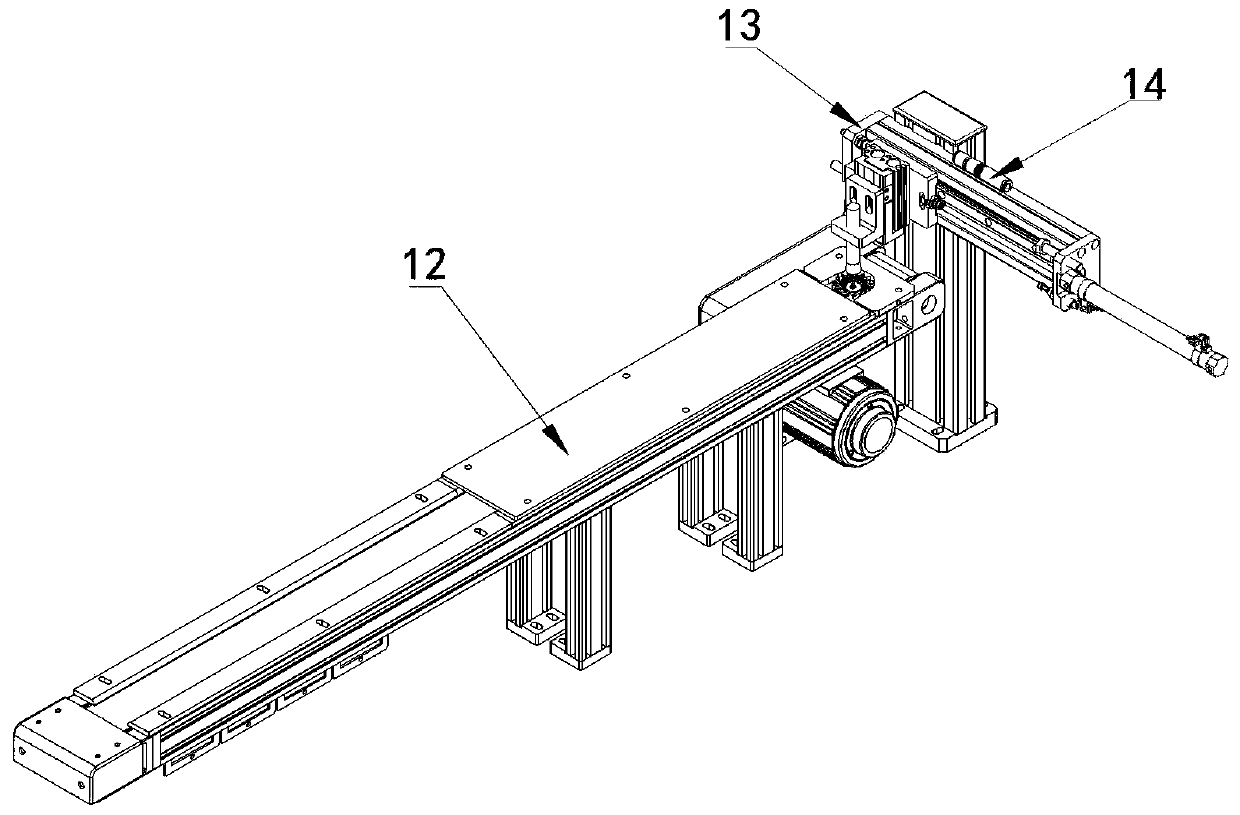

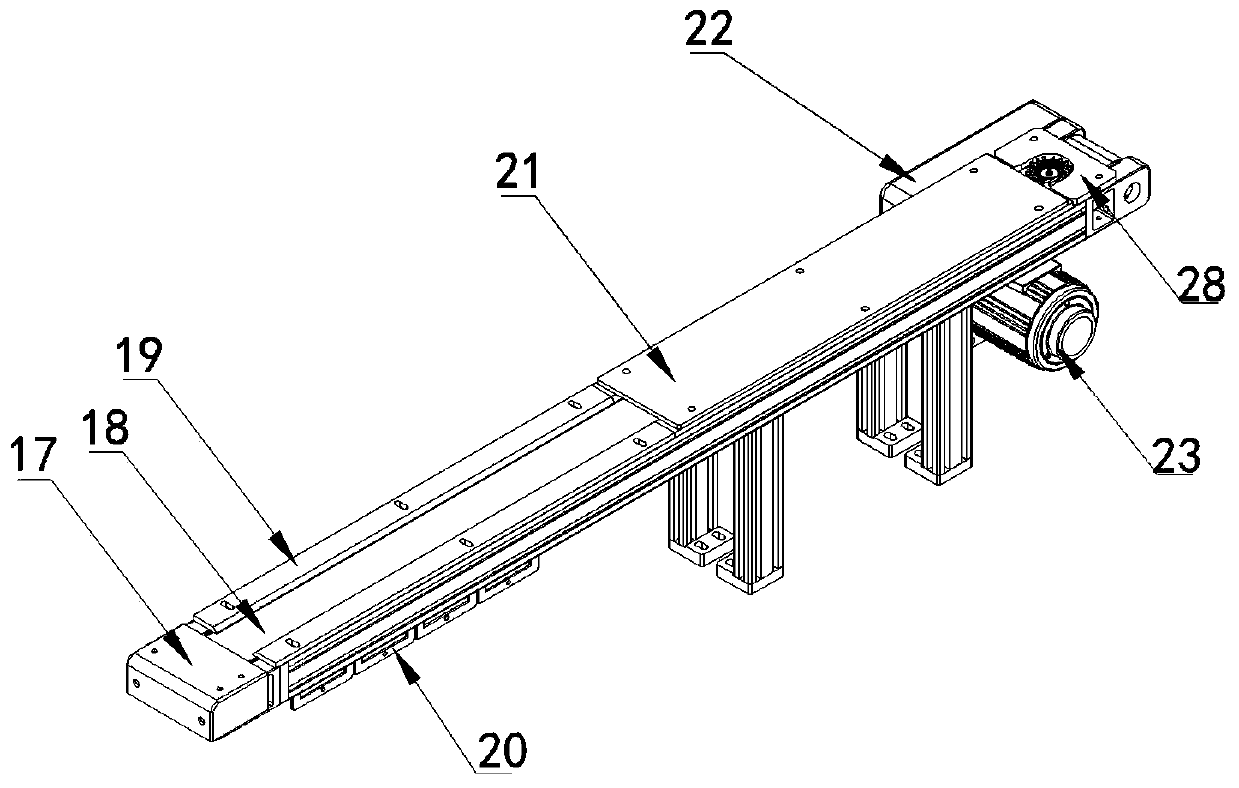

[0073] Figure 1 to Figure 43 In the shown embodiment, a fan winding machine includes a winding frame 11, and also includes a feeding mechanism 1, a discharging mechanism 2, an oil lock spraying and testing mechanism 3, and a coating mechanism installed on the winding frame. Glue mechanism 4, indexing plate for assembly 5, magnetic ring press-in mechanism 6, magnetic coiling mechanism 7, indexing plate for magnetic coiling 8, height detection mechanism 9 and magnetic ring magnetizing mechanism 10, the inner end and outlet of the feeding mechanism Between the inner ends of the feeding mechanism, there are oil-locking spraying and testing mechanisms, glue coating mechanisms, indexing plates for assembly, magnetic ring pressing mechanisms, magnetic coiling mechanisms, indexing plates for magnetic coiling, height detection mechanisms and magnetic ring charging. Magnetic mechanism, oil lock spraying and detection mechanism, glue application mechanism, magnetic ring pressing mechani...

Embodiment 2

[0093] A magnetic winding assembly method for a fan magnetic winding machine, comprising the following assembly steps

[0094] a. Place the fan blade casing on the feeding belt line provided by the feeding mechanism described in Example 1, and the conveying drive drives the fan blade casing to reach the feeding traverse module set by the feeding mechanism;

[0095] b The reclaiming cylinder in the feed traverse module moves down, the vacuum nozzle moves, and after sucking the fan blade casing, the reclaim cylinder rises, and the traverse cylinder in the feed traverse module moves to move to the fan blade casing When reaching above the accompanying jig set on the assembly index plate described in Example 1, the reclaiming cylinder descends to the accompanying jig, the vacuum nozzle releases the fan blade shell, then the reclaiming cylinder rises, and the traverse cylinder moves return to original position;

[0096] c The iron ring induction mechanism described in embodiment 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com