Preparation of a silicon carbide reactor and its application in the process of direct methane to olefins

A technology of silicon carbide and reactors, which is applied in new reactors, aromatics and hydrogen processes, and direct conversion of methane to ethylene. It can solve problems such as inability to promote industrialization, low mechanical strength, and difficult connections, and achieve redox and hydrothermal Good stability, less difficulty in industrialization, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

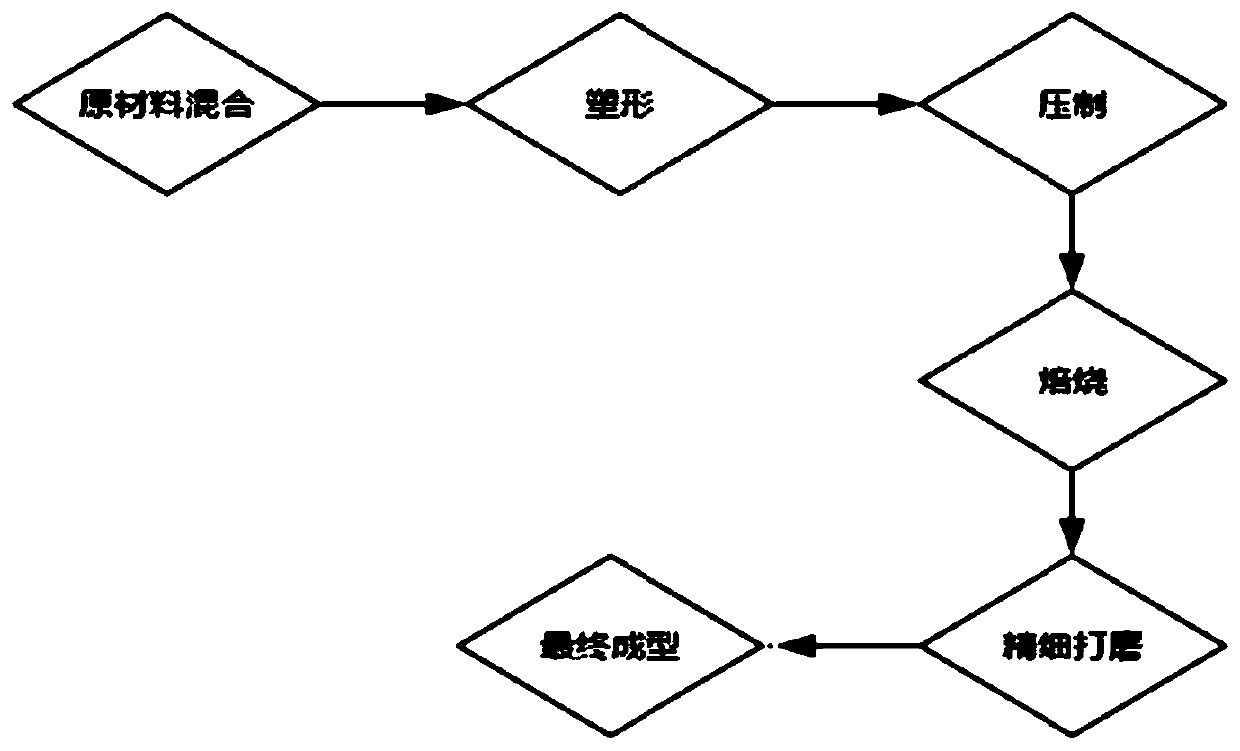

Method used

Image

Examples

Embodiment 1

[0036] Mix 1kg SiC powder, 300g high-purity graphite powder, 300g silicon powder, 20g ferric nitrate, 100mL epoxy resin, and 100mL water. The SiC powder is α-SiC with a particle size of 100-400nm and silicon powder with a particle size of 100μm. , sent to the extruder for extruded molding, the forming reactor is a straight tube, 2 meters in length, 35mm in outer diameter, 25mm in inner diameter, after 4 days of natural drying, it is sent to a 50°C muffle furnace to continue drying and dehumidification, and continue to dry in the N 2 Under the protection of , it was treated in a high-temperature furnace at 2000°C for 2 days, taken out after cooling down, and the surface of the reactor was finely polished to obtain reactor R1.

Embodiment 2

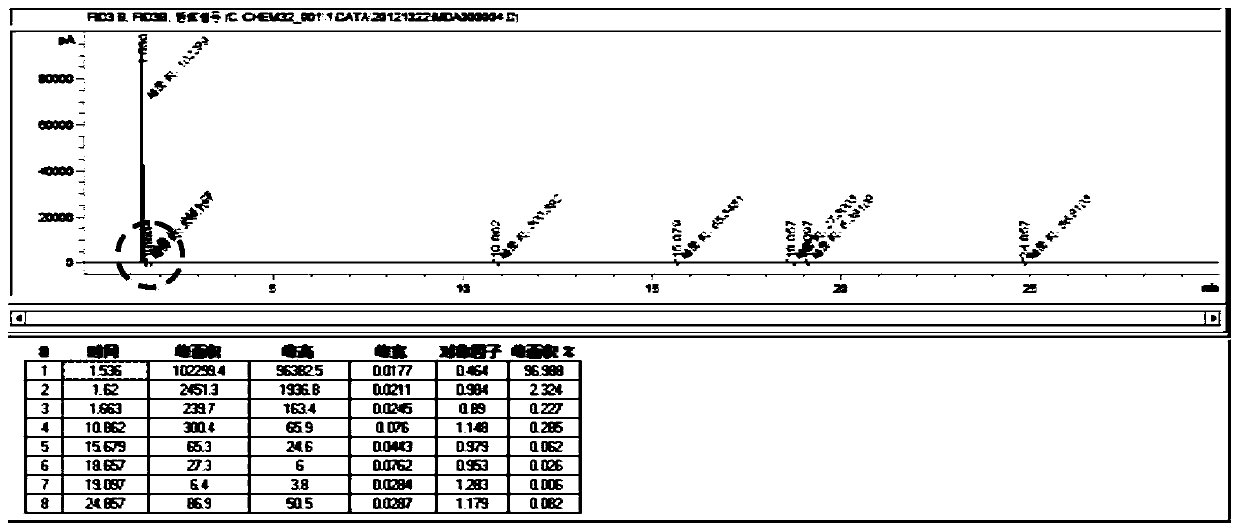

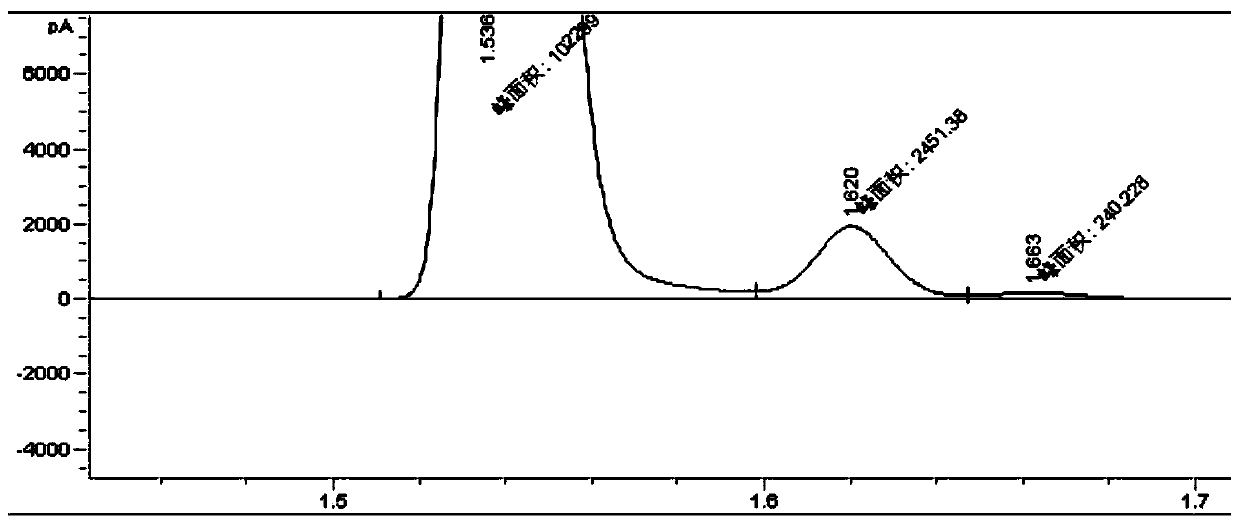

[0038] Mix 1kg SiC powder, 200g high-purity graphite powder, 200g silicon powder, 20g ferric chloride, 100mL epoxy resin, and 100mL water. The SiC powder is α-SiC with a particle size of 300-1000nm. 100 μm, sent to the extruder for extruded molding, the forming reactor is a straight tube type, 2 meters in length, 15mm in outer diameter, 5mm in inner diameter, after 4 days of natural drying, it is sent to a muffle furnace at 50°C to continue drying and dehumidification, and then Carry out pressing treatment, pressing pressure is 100Mpa, and pressing time is 30 minutes. continue at N 2 Under the protection of , it was treated in a high-temperature furnace at 2000°C for 3 days, taken out after cooling down, and the surface of the reactor was finely polished to obtain reactor R2. figure 2 It is the proton fluorescence spectrogram of the inner wall of the reactor, and the bright spots are Fe atoms, indicating that the distribution of Fe is very uniform.

Embodiment 3

[0040] Mix 1kg SiC powder, 100g carbon black powder, 100g silica powder, 40g nickel chloride, 200mL epoxy resin, and 200mL water evenly. The SiC powder is α-SiC with a particle size of 300-500μm, and the silica The particle size of the powder is 200μm, and it is sent to the extruder for extrusion molding. The forming reactor is a straight tube type, with a length of 2 meters, an outer diameter of 25mm, and an inner diameter of 15mm. After natural drying for 4 days, it is sent to a muffle furnace at 50°C for further drying. Dehumidification continues at N 2 Under the protection of the reactor, it was treated in a high-temperature furnace at 2000°C for 4 days, taken out after cooling down, and the surface of the reactor was finely polished to obtain reactor R3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com