Gynecological nursing disinfector with temperature control function

A sterilizer and gynecological technology, applied in the field of medical devices, can solve the problems of increasing the difficulty of medical staff's work, detrimental to the health of patients, and inability to replace parts, etc., and achieve the effects of comprehensive disinfection, improved disinfection efficiency, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The following is attached Figure 1-6 The present invention is described in further detail.

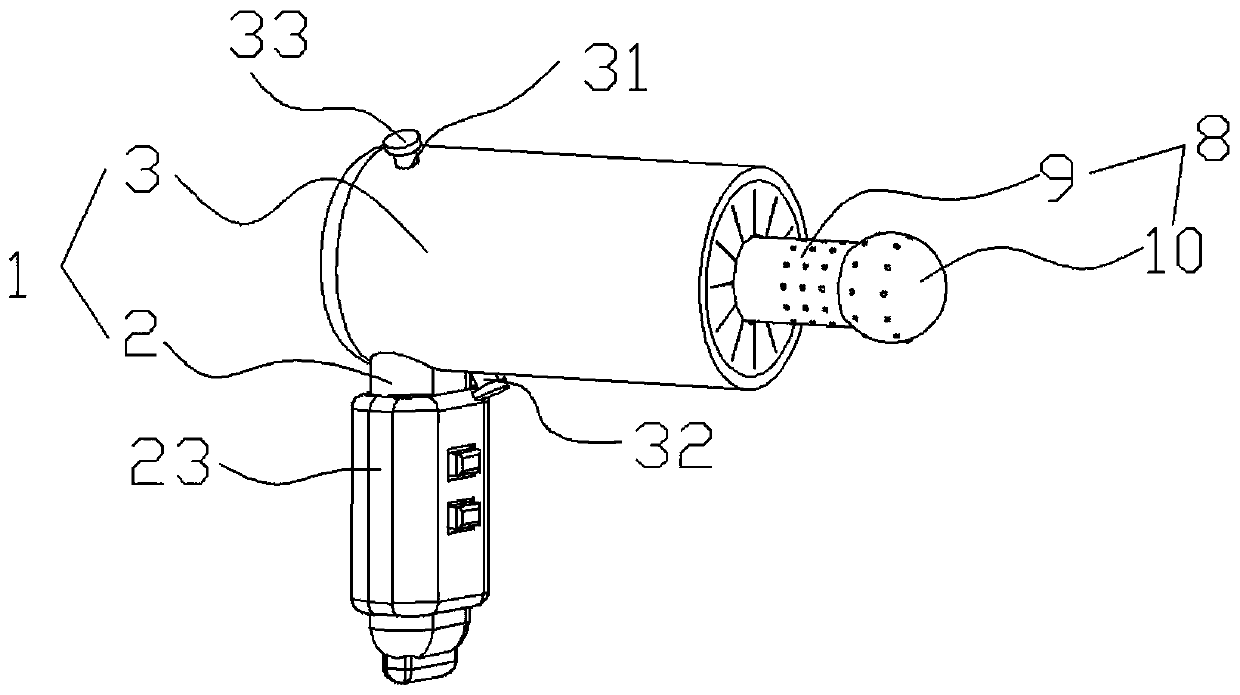

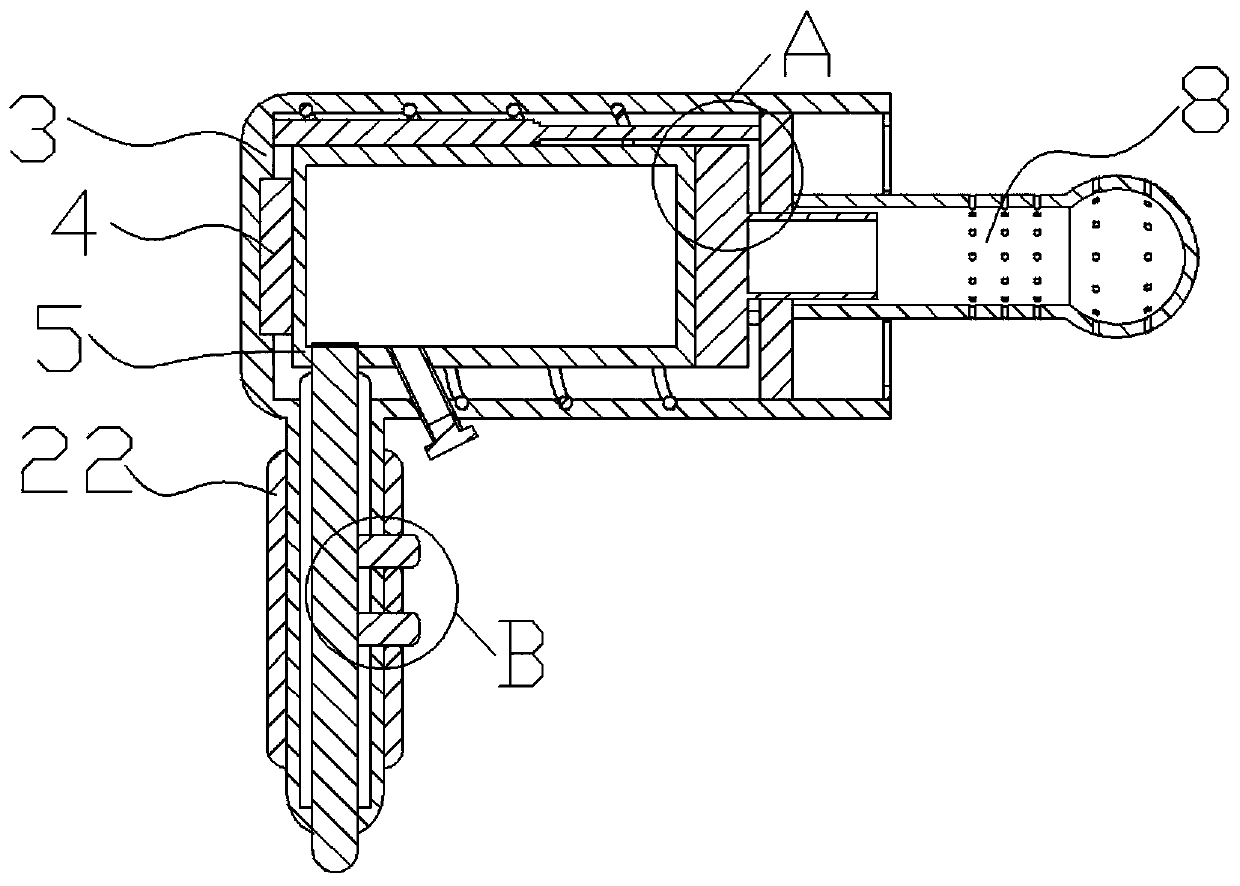

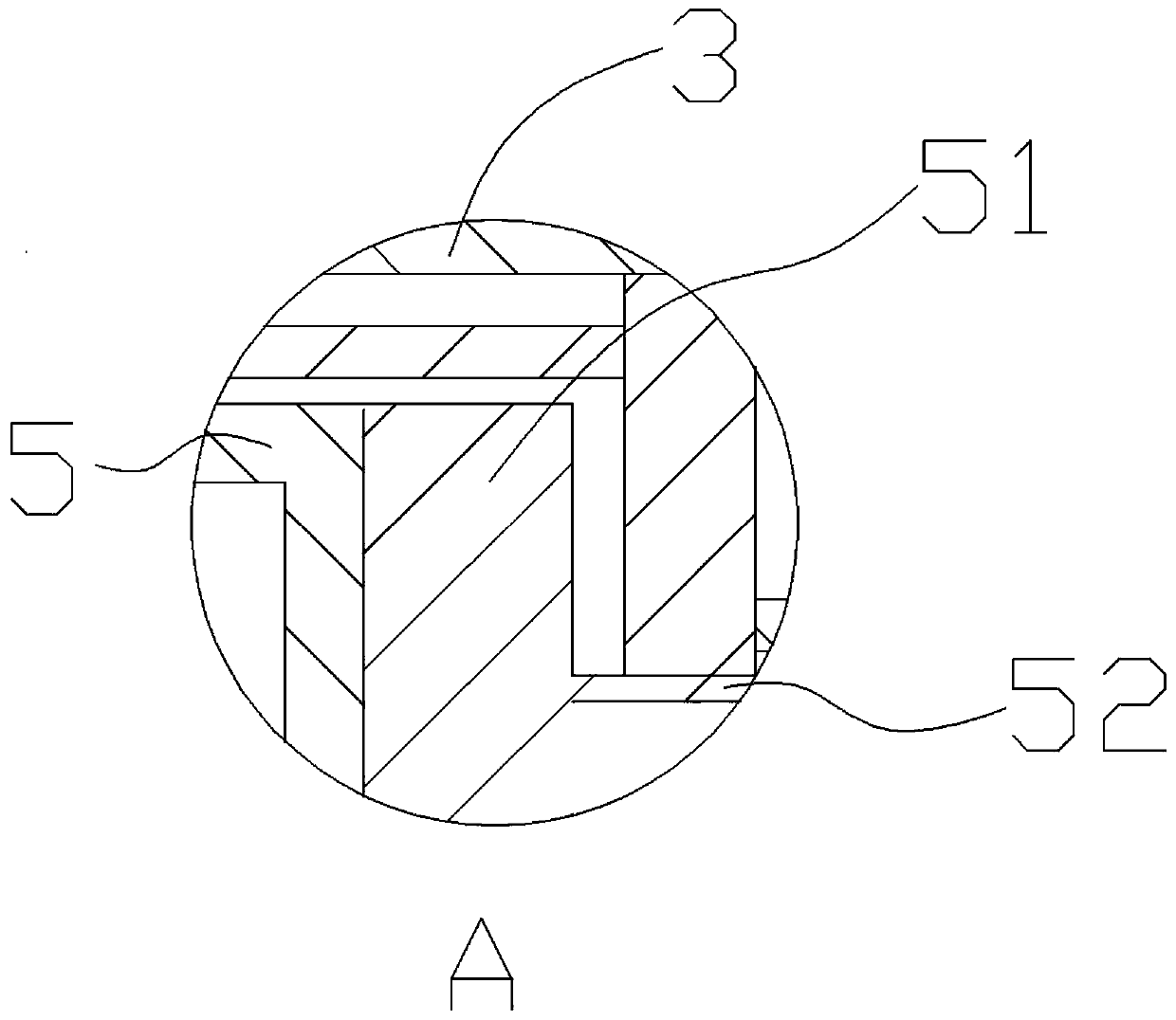

[0035] A gynecological care sterilizer with temperature control, such as figure 1 As shown, a gynecological care sterilizer with temperature control includes a fixing device 1 and a disinfection device 8, the fixing device 1 is slidably connected with the disinfection device 8, and the disinfection device 8 slides in the fixing device 1; the fixing device 1 includes a manual The handle 2 and the outer shell 3 are vertically and fixedly connected to the handle 2 and the outer shell 3. The disinfection device 8 includes a disinfection tube 9 and a disinfection ball 10. The disinfection tube 9 is fixedly connected to the sterilizer, and the disinfection tube 9 and the disinfection ball 10 are integrated. Formed, the disinfection device 8 is columnar and can go deep into the inside of the vagina to disinfect the inside of the vagina. At the same time, the existence of the fixing d...

Embodiment 2

[0044] The difference from Example 1 is that the outer casing 3 is coated with a waterproof and heat-insulating layer, and the preparation method of the waterproof and heat-insulating layer is:

[0045] Take the following components by weight for subsequent use: 25 parts of closed-cell perlite, 3 parts of titanium dioxide, 7 parts of asbestos fiber, 4 parts of barium sulfate, 2 parts of aluminum oxide, 0.3 part of sodium phosphate, 3 parts of polyvinyl alcohol, polyvinyl alcohol, Acrylic emulsion 6 parts, water 30 parts.

[0046] Its preparation method comprises the following steps:

[0047] S1. Uniformly mix closed-cell perlite, asbestos fiber, barium sulfate, aluminum oxide and sodium phosphate to obtain solid mixture A, which is set aside;

[0048] S2. Add titanium dioxide, polyvinyl alcohol, and polyacrylic acid emulsion into water, and homogenize to obtain mixed liquid B. The homogenization speed is 3800r / min, and the time is 13 minutes; , set aside;

[0049] S3. When i...

Embodiment 3

[0052] The difference from Example 2 is that the specific gravity of the formula has been modified, and the modified formula is:

[0053] Take the following components by weight for subsequent use: 27 parts of closed-cell perlite, 4 parts of titanium dioxide, 5 parts of asbestos fiber, 3 parts of barium sulfate, 2 parts of aluminum oxide, 0.4 part of sodium phosphate, 5 parts of polyvinyl alcohol, polyvinyl alcohol, 7 parts of acrylic emulsion, 35 parts of water.

[0054] Its preparation method comprises the following steps:

[0055] S1. Uniformly mix closed-cell perlite, asbestos fiber, barium sulfate, aluminum oxide and sodium phosphate to obtain solid mixture A, which is set aside;

[0056] S2. Add titanium dioxide, polyvinyl alcohol, and polyacrylic acid emulsion into water, and homogenize to obtain mixed liquid B. The homogenization speed is 3800r / min, and the time is 13 minutes; , set aside;

[0057] S3. When in use, mix steps S1 and S2, stir evenly, and stir at a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com