Sodium vanadium fluorophosphate and carbon compound and preparation method and application thereof

A technology of sodium vanadium fluorophosphate and carbon composites, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of high energy consumption and complicated preparation process, achieve large specific surface area, improve rate performance, prevent The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

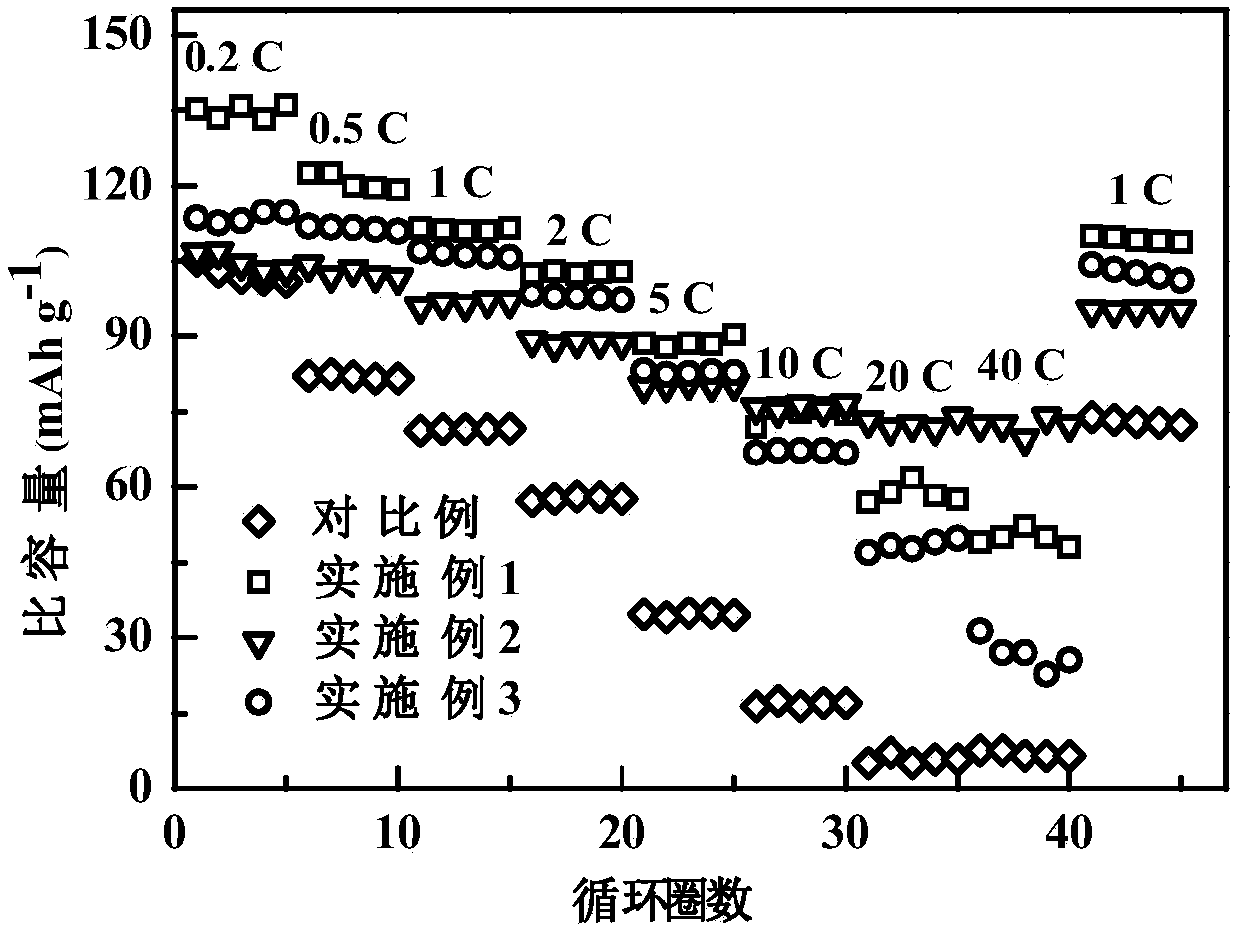

[0022] Embodiment 1: (VPO 4 Preparation of Na by Low Temperature In Situ Carbonization 3 V 2 (PO 4 ) 2 f 3 carbon composite)

[0023] Weigh 0.315g sodium fluoride (both as fluorine source and sodium source), 0.649g vanadium phosphate (both as vanadium source and phosphate), 0.3gSDS (sodium dodecyl sulfate), 1.2g glucose, Add it to a 100mL hydrothermal kettle, add 25ml ethanol and 25ml deionized water, and react at 180°C for 48h. The resulting mixed solution was filtered with filter paper, washed three times with deionized water and ethanol, and then placed in an oven at 120 °C for 8 h to obtain Na 3 V 2 (PO 4 ) 2 f 3 carbon composite. The prepared Na 3 V 2 (PO 4 ) 2 f 3 The carbon composite is used as the positive electrode, the metal sodium sheet is used as the negative electrode, the glass fiber membrane is used as the separator, and the solute is 1MNaClO 4, the solvent EC (ethylene carbonate) and DEC (diethyl carbonate) mixture (mass ratio 1:1), the additiv...

Embodiment 2

[0024] Embodiment 2: (NH 4 VO 3 Preparation of Na by Low Temperature In Situ Carbonization 3 V 2 (PO 4 ) 2 f 3 carbon composite)

[0025] Weigh 0.315g sodium fluoride (both as fluorine source and sodium source), 0.585g ammonium metavanadate, 0.5752g ammonium dihydrogen phosphate, 1.0507g citric acid monohydrate, 0.3g PEG-6000, 0.9g starch, Add it to a 100mL hydrothermal kettle, add 25ml of acetone and 25ml of deionized water, and react at 140°C for 36h. The resulting mixed solution was filtered with filter paper, washed three times with deionized water and ethanol, and then placed in an oven at 120 °C for 8 h to obtain Na 3 V 2 (PO 4 ) 2 f 3 carbon composite.

Embodiment 3

[0026] Embodiment 3: (V 2 o 5 Preparation of Na by Low Temperature In Situ Carbonization 3 V 2 (PO 4 ) 2 f 3 carbon composite)

[0027] Weigh 0.278g ammonium fluoride, 0.300g sodium hydroxide, 0.455g vanadium pentoxide, 0.5752g ammonium dihydrogen phosphate, 1.0507g citric acid monohydrate, 1.5g sucrose, add to a 100mL hydrothermal kettle, add 25ml Acetone and 25ml deionized water were reacted at 120°C for 48h. The resulting mixed solution was filtered with filter paper, washed three times with deionized water and ethanol, and then placed in an oven at 120 °C for 8 h to obtain Na 3 V 2 (PO 4 ) 2 f 3 carbon composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com