Novel ceramic low-expansion isolation medium-voltage fire-resistant cable

A fire-resistant cable and low-expansion technology, which is applied in the direction of insulated cables, power cables with shielding layers/conductive layers, cables, etc., can solve the problems of dense smoke, heavy weight, and short fire-resistant time, so as to prevent flames from spreading. Unobstructed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

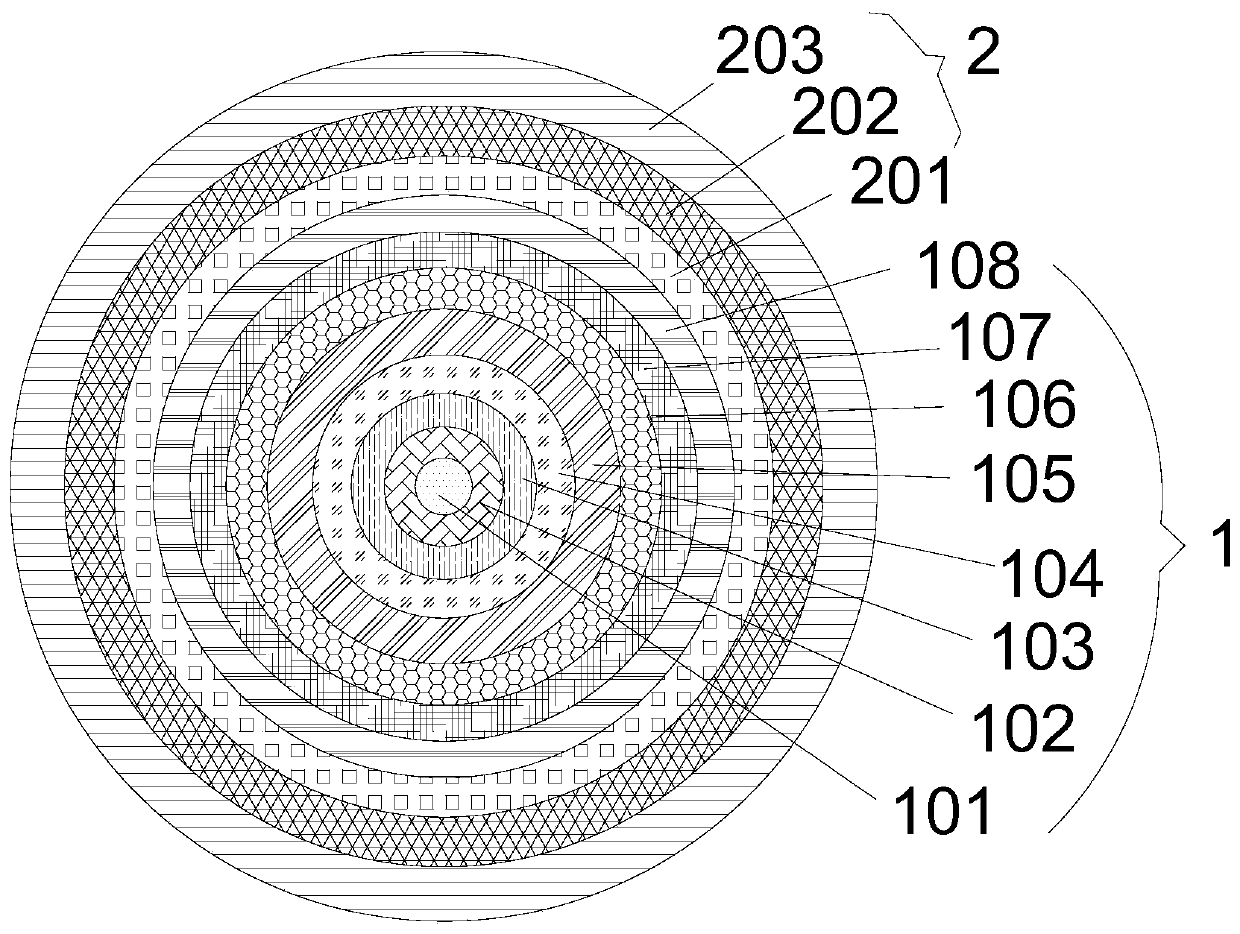

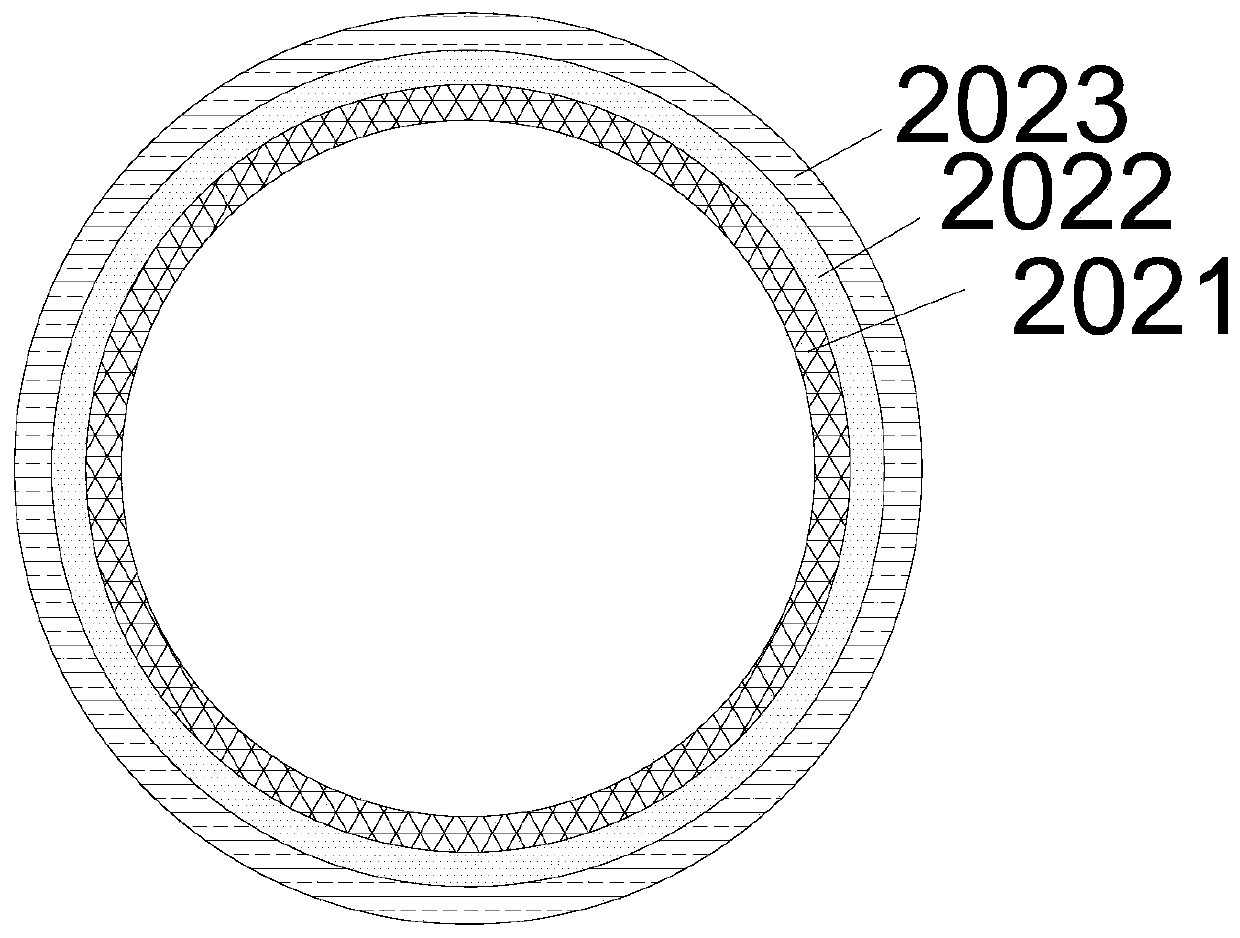

[0033] Please refer to Figure 1 to Figure 2 As shown, this embodiment provides a new ceramic low-expansion isolated medium-voltage fire-resistant cable, including a cable core 1 and a heat-insulating fire-resistant layer 2. The heat-insulating fire-resistant layer 2 includes an oxygen barrier layer 201, The refractory layer 202 and the outer sheath 203, the oxygen barrier layer 201, the refractory layer 202, and the outer sheath 203 are sequentially wrapped on the outside of the cable core 1, and the cable core 1 includes a conductor 101 and a conductor shielding layer 102 from the inside to the outside. , an insulating layer 103, an insulating shielding layer 104, a first buffer layer 105, a metal shielding layer 106, a second buffer layer 107 and a longitudinal cladding argon arc welding aluminum sheath layer 108, the first buffer layer 105 and the second buffer layer 107 The material is semiconducting resistance water expansion belt.

[0034] Specifically: the conductor 1...

Embodiment 2

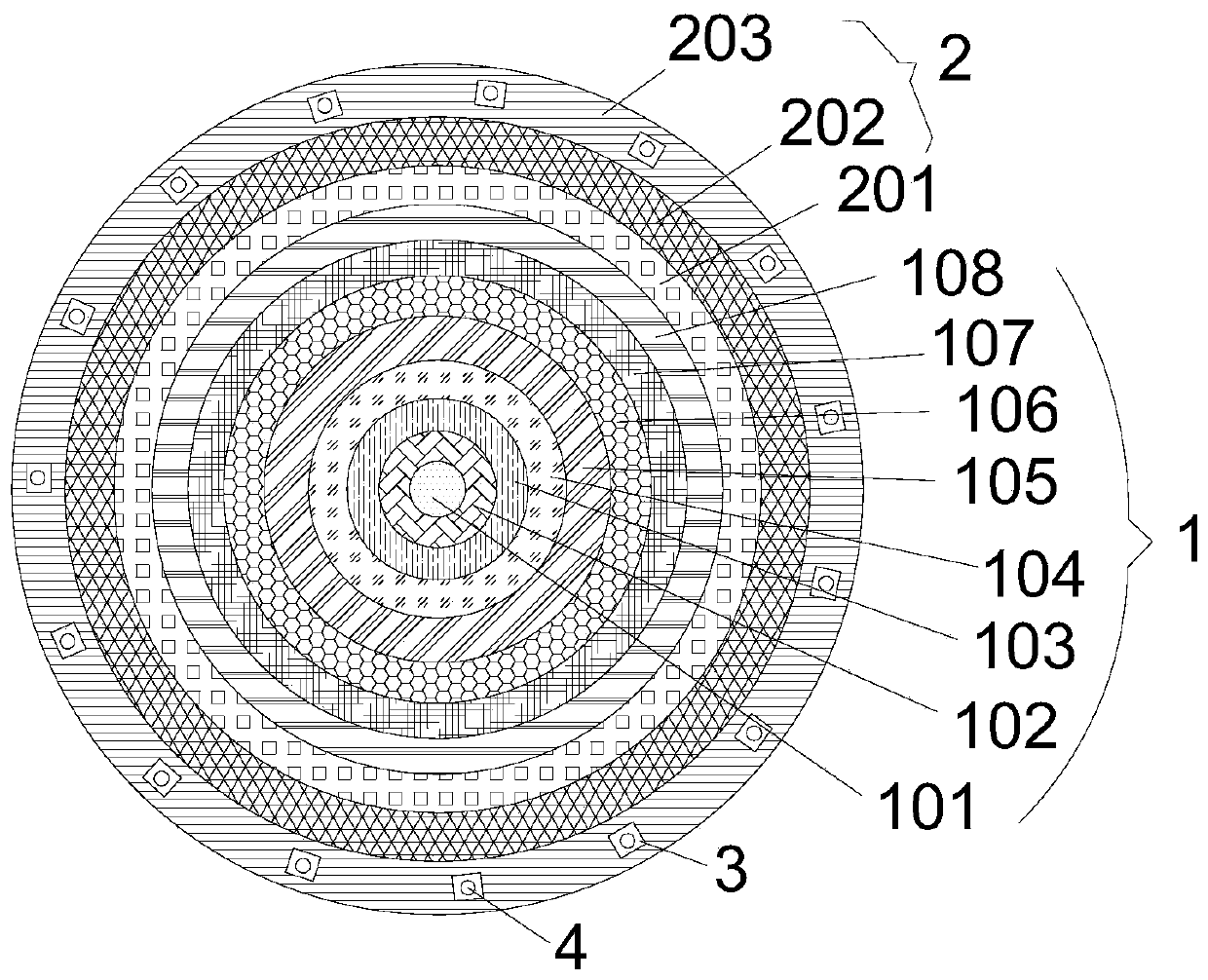

[0048] Please refer to figure 2 and image 3 As shown, this embodiment provides a new type of ceramic low-expansion isolated medium-voltage fire-resistant cable. Except for all the technical features in Embodiment 1, the difference lies in: several airtight seals are processed on the sheath layer 203. Inner cavity 3, the sealed inner cavity 3 is filled with fire extinguishing agent unit 4. The advantage of this design is that during the burning process of the cable, the fire extinguishing agent unit 4 in the sealed inner cavity 3 will be released after the sheath burns to realize fire extinguishing Features.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com