Oil-soluble film-coated particle flow regulator and its preparation method and application

An oil-soluble, flow-regulating agent technology, applied in chemical instruments and methods, mining fluids, earthwork drilling and production, etc., can solve problems such as complex components of flow-regulating agents, poor oil-water selectivity, difficulty in adapting to high-temperature and high-salinity formations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a kind of preparation method of above-mentioned film-coated particle flow regulator, and the method comprises the following steps:

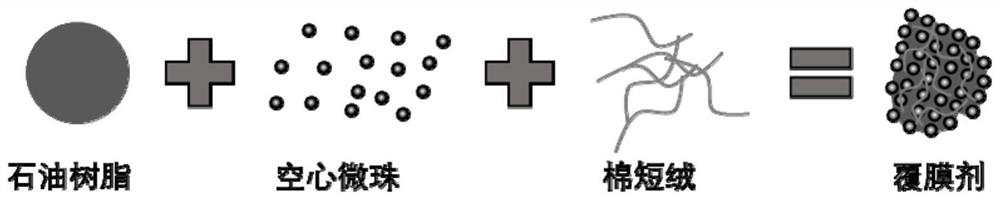

[0041] (1) Petroleum resin is mixed with hollow microspheres in molten state;

[0042] (2) adding cotton linters to the mixture obtained in step (1) to obtain a coating agent;

[0043] (3) The coating agent obtained in step (2) is used to coat the coating core to obtain the oil-soluble coating particle flow regulator.

[0044] Wherein, the molten state of the petroleum resin refers to the state in which the petroleum resin changes from solid to liquid.

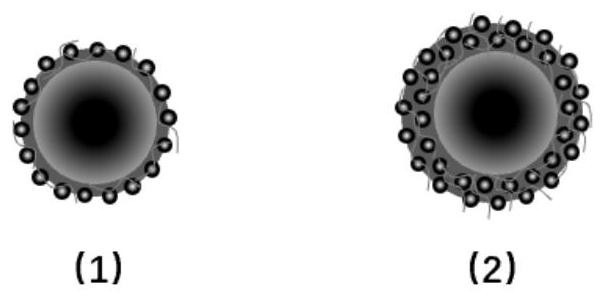

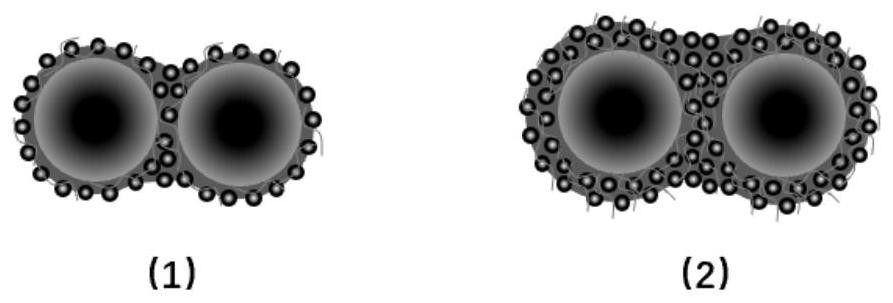

[0045] According to the preparation method of the present invention, the preparation of coating agent (such as figure 1 As shown), the petroleum resin is melted at high temperature to reach a fluid state. In the molten petroleum resin, first add hollow microspheres and mix uniformly, then add cotton linters, mix uniformly, and obtain a coating agent (s...

Embodiment 1

[0069] This example is used to illustrate the film-coated particle flow regulator provided by the present invention and its preparation method.

[0070] (1) Take 100g of C9 petroleum resin with a density of 1.15g / cm 3 , melted at a high temperature of 180°C for later use; take 50g of hollow glass microspheres, density 0.4g / cm 3 , particle size 20 μm, add in high-temperature molten petroleum resin and mix evenly, finally add 15g of cotton linters; stir the mixture evenly to obtain a coating agent with an apparent density of 0.75g / cm 3 ;

[0071] (2) Take 100g of regenerated rubber particles, density 1.3g / cm 3 , with a particle size of 2mm, put it into the fluidized bed, and use hot air to blow it up; spray the above coating agent on the upper part of the fluidized bed to coat the particles, and when the thickness of the shell layer reaches 0.32mm, increase the air velocity to carry out Blow it out, then carry out air cooling and cyclone separation to obtain a film-coated par...

Embodiment 2

[0073] This example is used to illustrate the film-coated particle flow regulator provided by the present invention and its preparation method.

[0074] (1) Take 75g of C9 petroleum resin with a density of 1.15g / cm 3, melted at a high temperature of 180°C for later use; take 50g of hollow glass microspheres with a density of 0.4g / cm 3 , particle size 30μm, add high-temperature molten petroleum resin and mix evenly, finally add 10g of cotton linters; stir the mixed material evenly to obtain a coating agent with an apparent density of 0.69g / cm 3 ;

[0075] (2) Get 125g of regenerated rubber particles, density 1.3g / cm 3 , with a particle size of 1mm, put it into the bottom of the fluidized bed, and use hot air to blow it up; spray the above-mentioned coating agent on the upper part of the fluidized bed to coat the particles, and when the thickness of the shell layer reaches 0.1mm, increase the air velocity to carry out Blow it out, then carry out air cooling and cyclone separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com