Bridge damping device

A vibration damping device and bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of single vibration damping facilities and poor vibration damping effect, and achieve the goal of ensuring vibration damping effect, simple structure, and bridge safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

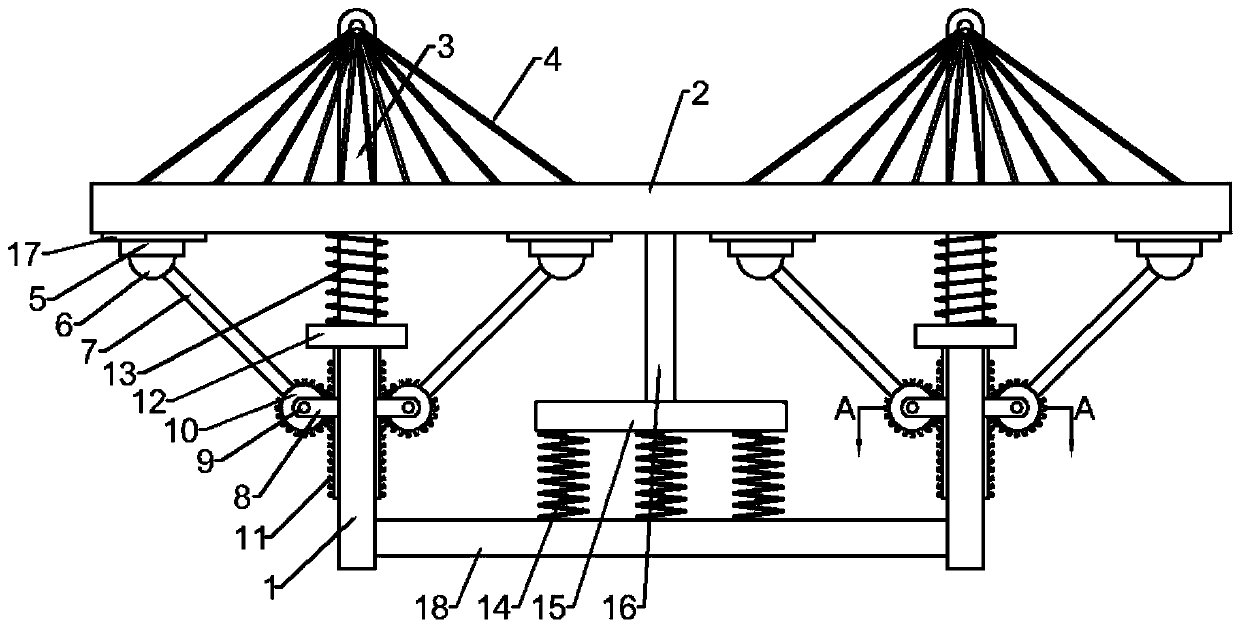

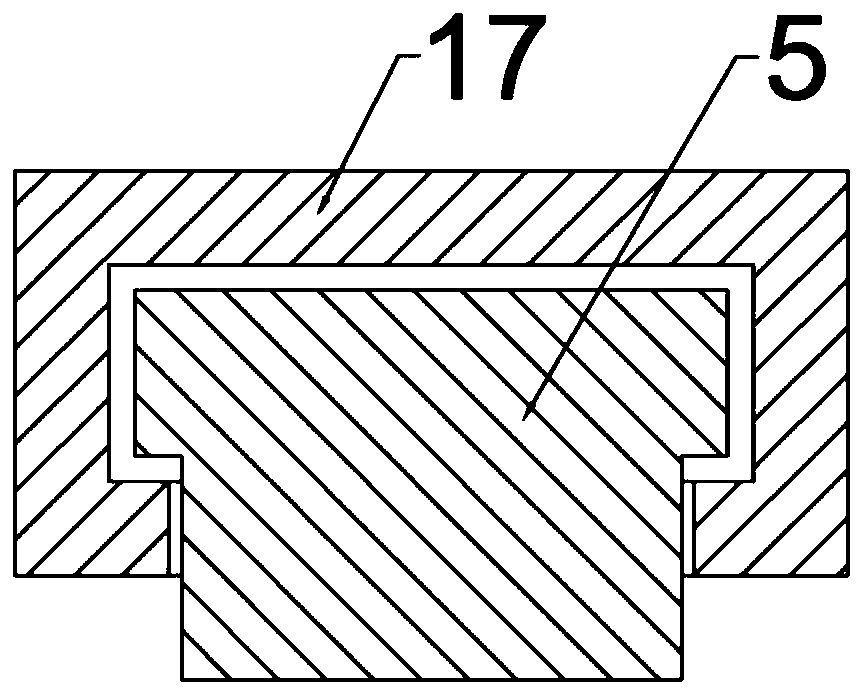

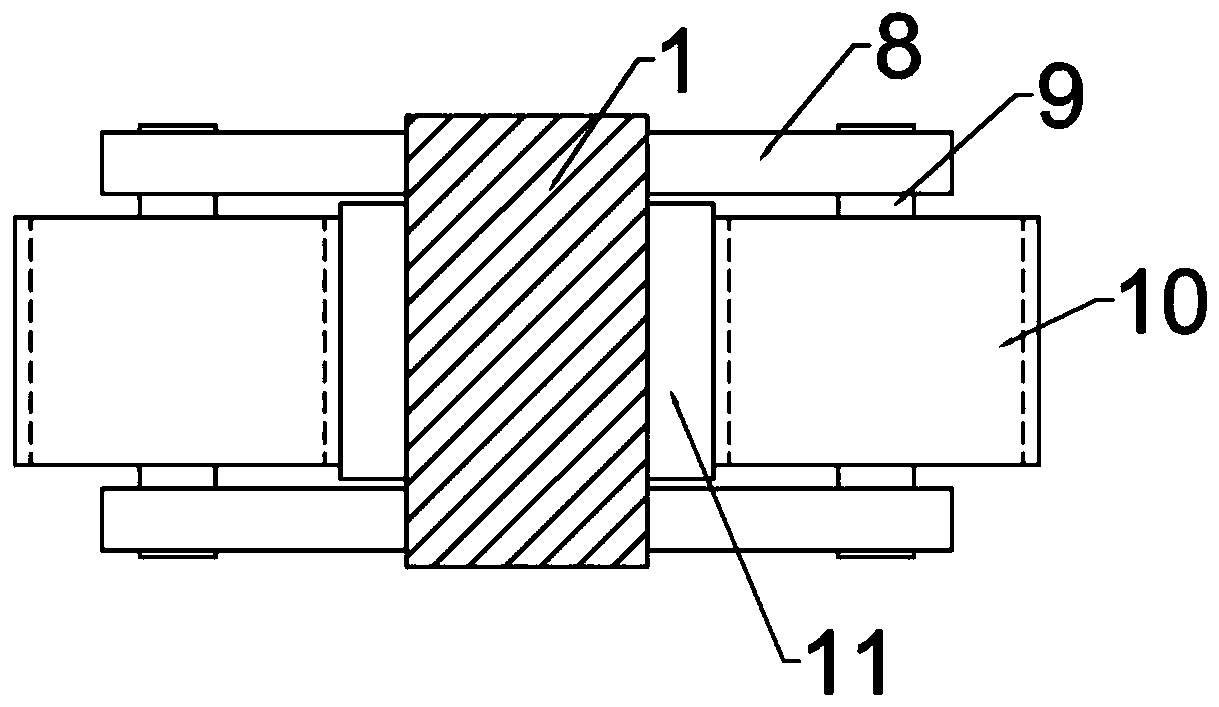

[0020] Example 1: Please refer to Figure 1-3 , a bridge damping device, comprising a plurality of supporting piers 1, the top of the supporting piers 1 is fixedly connected with a bridge deck 2, the bridge deck 2 is slidingly connected with the supporting piers 1 by bolts, and the left and right sides of the supporting piers 1 are fixedly connected There is a limit chute 17 located below the bridge deck 2, the inside of the limit chute 17 is slidably connected with a limit slider 5, and the bottom of the limit slider 5 is fixedly connected with a rotary hinge 6, and the bottom of the rotary hinge 6 is fixed. A swing connecting rod 7 is connected, the middle part of the supporting pier 1 is fixedly connected with a bearing bracket 8, the outside of the bearing bracket 8 is rotatably connected with a positioning shaft 9, and the outside of the positioning shaft 9 is fixedly connected with a driven gear 10, and the driven gear 10 is connected with the swing connecting rod 7 The ...

Embodiment 2

[0025] Embodiment 2: This embodiment is a further improvement of the previous embodiment: a support connecting bottom bar 18 is fixedly connected between the adjacent supporting piers 1, and a number of second springs 14 are fixedly connected above the supporting connecting bottom bar 18. The top of the second spring 14 is fixedly connected with a horizontal damping base plate 15, and the top of the horizontal damping base plate 15 is fixedly connected with a vibration damping support rod 16. The vibration damping support rod 16 is fixed on the bottom of the bridge deck 2. The horizontal damping bottom plate 15 is driven downward by supporting the connecting bottom bar 18 to press the second spring 14, and the second spring 14 will further dampen the vibration, improve the stability of the bridge, and ensure safety.

[0026] The fixed connection position between the vibration-damping support rod 16 and the bridge deck 2 is located in the middle of the adjacent supporting pier 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com