Method for repairing saline-alkali soil

A saline-alkali soil and remediation agent technology, applied in the field of agricultural soil remediation, can solve the problems of uncontrollable upturning of saline-alkali, narrow application range, unsatisfactory effect, etc., achieve good promotion and application value, small equipment dependence, and easy scale The effect of chemical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

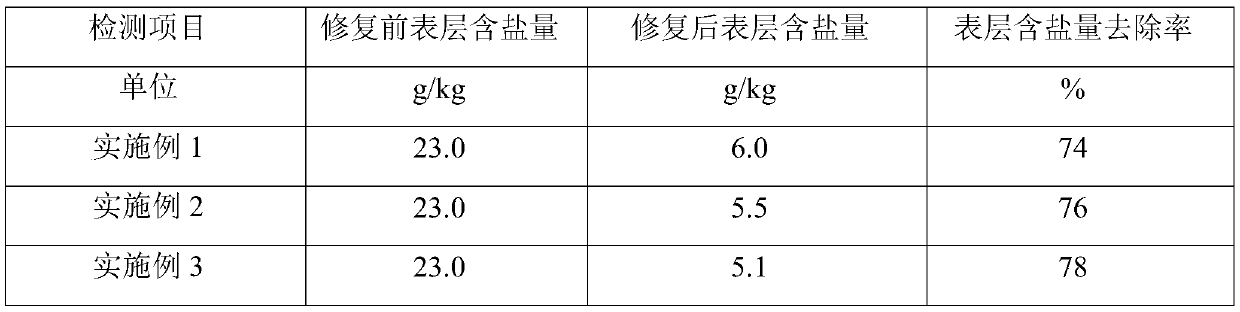

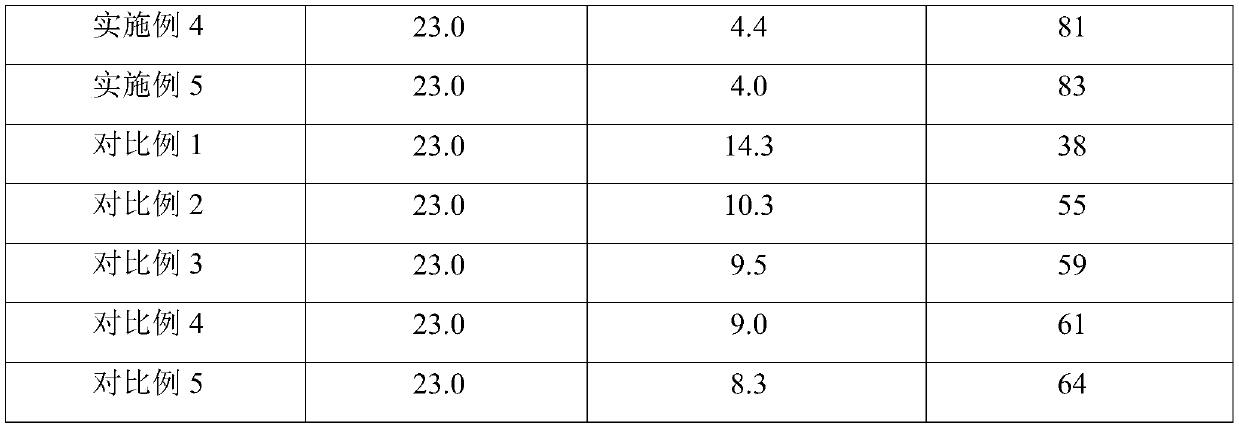

Examples

Embodiment 1

[0028] A saline-alkali soil remediation agent is made of the following raw materials in parts by weight: 25 parts based on ferrous fumarate organic acid copolymer, 5 parts of seaweed powder, 15 parts of microbial fertilizer, 10 parts of calcium lignosulfonate, 5 parts of humic acid, 50 parts of water.

[0029] The preparation method based on ferrous fumarate organic acid copolymer comprises the steps:

[0030] Step D1: Add 1.07kg of 4,4'-diaminostilbene-2,2'-disulfonic acid and 1kg of 9,12,13-trihydroxy-10,11-epoxyoctadecanoic acid to 6kg of tetrahydrofuran , stirred and reacted at 60°C for 6 hours, and then the solvent was removed by rotary evaporation to obtain a sulfonic acid group polymerized monomer;

[0031] Step D2: 2kg of the sulfonic acid group polymerized monomer prepared in step D1, 1kg of Tween 80, 0.5kg of ferrous fumarate, 1kg of N5-[(allyloxy)carbonyl]ornithine, azobis Add 0.02kg of isobutyronitrile to 15kg of N,N-dimethylformamide, stir and react under nitrog...

Embodiment 2

[0037]A saline-alkali soil remediation agent is made of the following raw materials in parts by weight: 26 parts based on ferrous fumarate organic acid copolymer, 6 parts of seaweed powder, 17 parts of microbial fertilizer, 11 parts of calcium lignosulfonate, 6 parts of humic acid, 52 parts of water.

[0038] The preparation method based on ferrous fumarate organic acid copolymer comprises the steps:

[0039] Step D1: Add 1.07kg of 4,4'-diaminostilbene-2,2'-disulfonic acid and 1kg of 9,12,13-trihydroxy-10,11-epoxyoctadecanoic acid to dichloro In 7.5kg of methane, stirred and reacted at 65°C for 6.5 hours, and then the solvent was removed by rotary evaporation to obtain a sulfonic acid group polymerized monomer;

[0040] Step D2: 2kg of the sulfonic acid group polymerized monomer prepared in step D1, 1kg of Tween 80, 0.5kg of ferrous fumarate, 1kg of N5-[(allyloxy)carbonyl]ornithine, azobis Add 0.025kg of isoheptanonitrile to 16.5kg of N,N-dimethylacetamide, stir and react un...

Embodiment 3

[0046] A saline-alkali soil remediation agent is made of the following raw materials in parts by weight: 29 parts based on ferrous fumarate organic acid copolymer, 7 parts of seaweed powder, 17 parts of microbial fertilizer, 13 parts of calcium lignosulfonate, 7 parts of humic acid, 55 parts of water.

[0047] The preparation method based on ferrous fumarate organic acid copolymer comprises the steps:

[0048] Step D1: Add 1.07kg of 4,4'-diaminostilbene-2,2'-disulfonic acid and 1kg of 9,12,13-trihydroxy-10,11-epoxyoctadecanoic acid to 8kg of acetone , stirred and reacted at 70°C for 7 hours, and then the solvent was removed by rotary evaporation to obtain a sulfonic acid group polymerized monomer;

[0049] Step D2: 2kg of the sulfonic acid group polymerized monomer prepared in step D1, 1kg of Tween 80, 0.5kg of ferrous fumarate, 1kg of N5-[(allyloxy)carbonyl]ornithine, azobis Add 0.03 kg of isobutyronitrile to 18 kg of N-methylpyrrolidone, stir and react under nitrogen atmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com