Self-repairing adhesive and preparation method and application thereof

An adhesive and self-healing technology, applied in the field of chemical energy storage, can solve the problems of volume expansion of alloy-type electrode materials, and achieve the effects of low cost, good self-healing ability and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

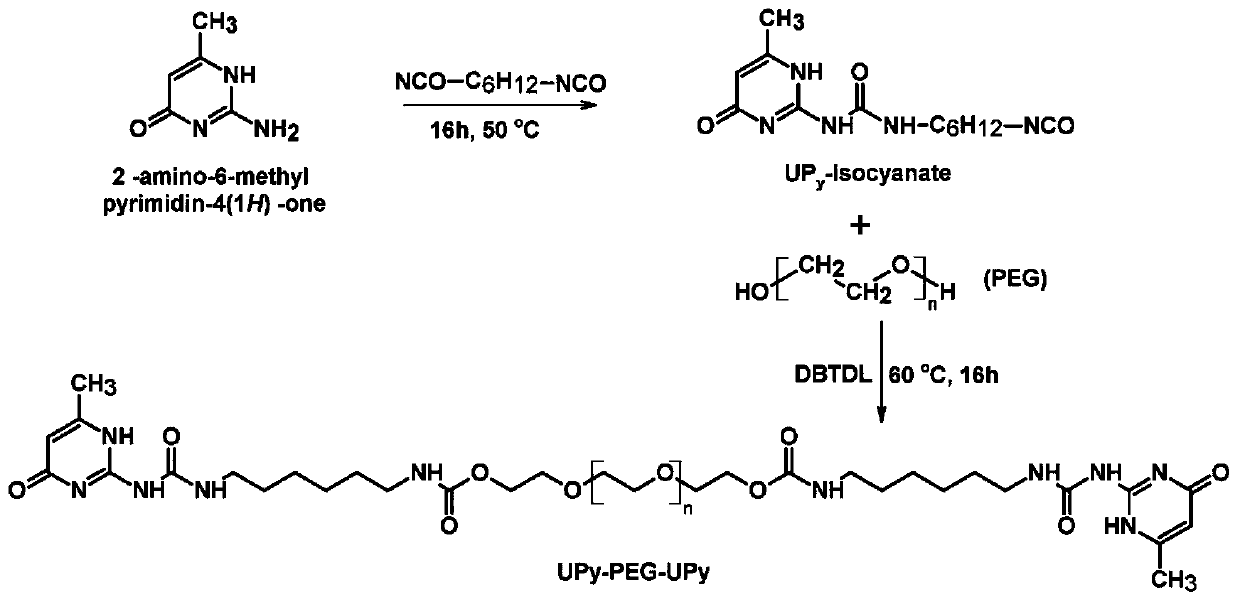

[0025] A self-healing adhesive is a UPy-PEG-UPy adhesive, and its specific structural formula is as follows:

[0026]

[0027] In the formula, n is 70.

[0028] A method for preparing a self-healing adhesive, the steps comprising

[0029] Step 1: Mix 2amino-6methyl-4[1H]-pyrimidinone and hexamethylene diisocyanate at a molar ratio of 1:0.8, heat to 45°C, and keep warm for 20 hours to prepare UPy-isocyanate;

[0030] Step 2: Dissolve polyethylene glycol, dibutyltin dilaurate and UPy-isocyanate in chloroform, wherein the molar ratio between polyethylene glycol, dibutyltin dilaurate and UPy-isocyanate is 1:0.01:3, After dissolving, heat it to 55° C., keep it warm for 20 hours, and obtain UPy-PEG-UPy adhesive after refluxing.

Embodiment 2

[0032] A self-healing adhesive is a UPy-PEG-UPy adhesive, and its specific structural formula is as follows:

[0033]

[0034] In the formula, n is 80.

[0035] combine figure 1 Shown, a kind of preparation method of self-healing adhesive, the step comprises

[0036] Step 1: Mix 2amino-6methyl-4[1H]-pyrimidinone and hexamethylene diisocyanate at a molar ratio of 1:1, heat to 50°C, and keep warm for 16 hours to prepare UPy-isocyanate;

[0037] Step 2: Polyethylene glycol, dibutyltin dilaurate and UPy-isocyanate are dissolved in chloroform, wherein the molar ratio between polyethylene glycol, dibutyltin dilaurate and UPy-isocyanate is 1:0.02:4, After dissolving, heat it to 60° C., keep it warm for 16 hours, and obtain the UPy-PEG-UPy adhesive after refluxing.

Embodiment 3

[0039] A self-healing adhesive is a UPy-PEG-UPy adhesive, and its specific structural formula is as follows:

[0040]

[0041] In the formula, n is 100.

[0042] A method for preparing a self-healing adhesive, the steps comprising

[0043] Step 1: Mix 2amino-6methyl-4[1H]-pyrimidinone and hexamethylene diisocyanate at a molar ratio of 1:1.2, heat to 55°C, and keep warm for 10 hours to prepare UPy-isocyanate;

[0044] Step 2: Polyethylene glycol, dibutyltin dilaurate and UPy-isocyanate are dissolved in chloroform, wherein the molar ratio between polyethylene glycol, dibutyltin dilaurate and UPy-isocyanate is 1:0.03:5, After dissolving, heat it to 65° C., keep it warm for 10 hours, and obtain the UPy-PEG-UPy adhesive after refluxing.

[0045] Taking Example 2 as an example, study its structure and performance:

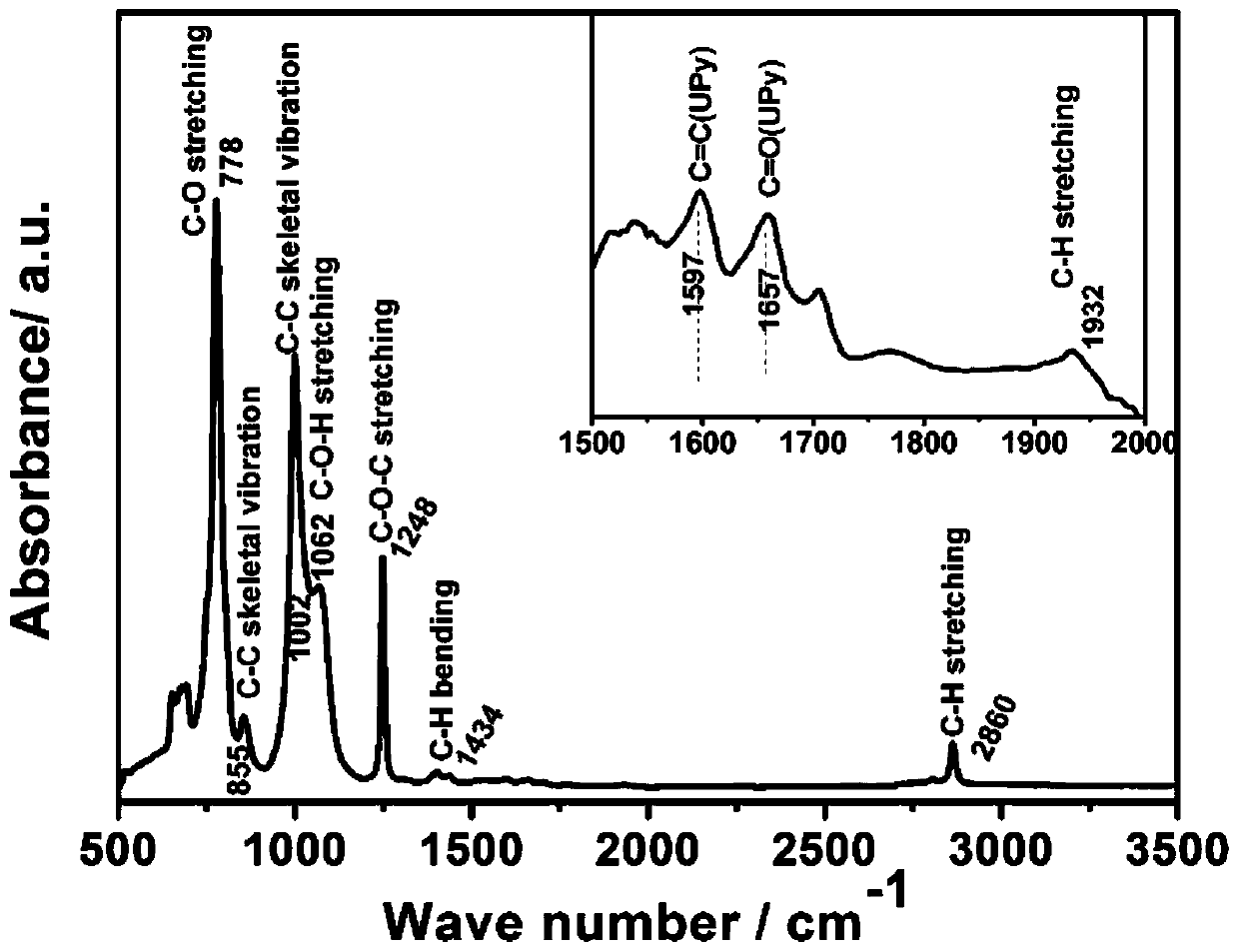

[0046] combine figure 2 Shown, in the infrared absorption spectrum can be seen, 1597 and 1657cm -1 and 1932cm -1 The three infrared absorption peaks at corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com