Active coating with self-healing function on magnesium-based surface and preparation method thereof

An active coating, self-healing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of the active coating with self-healing function on the magnesium-based surface comprises the following steps:

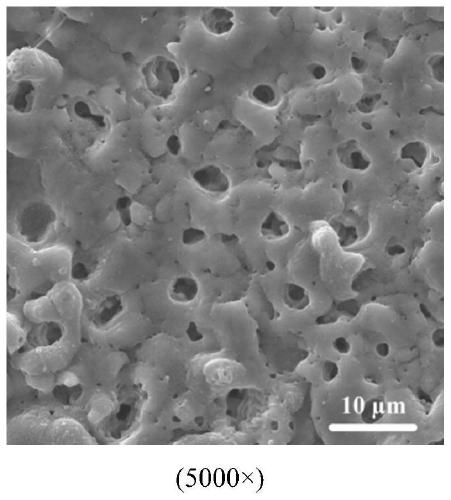

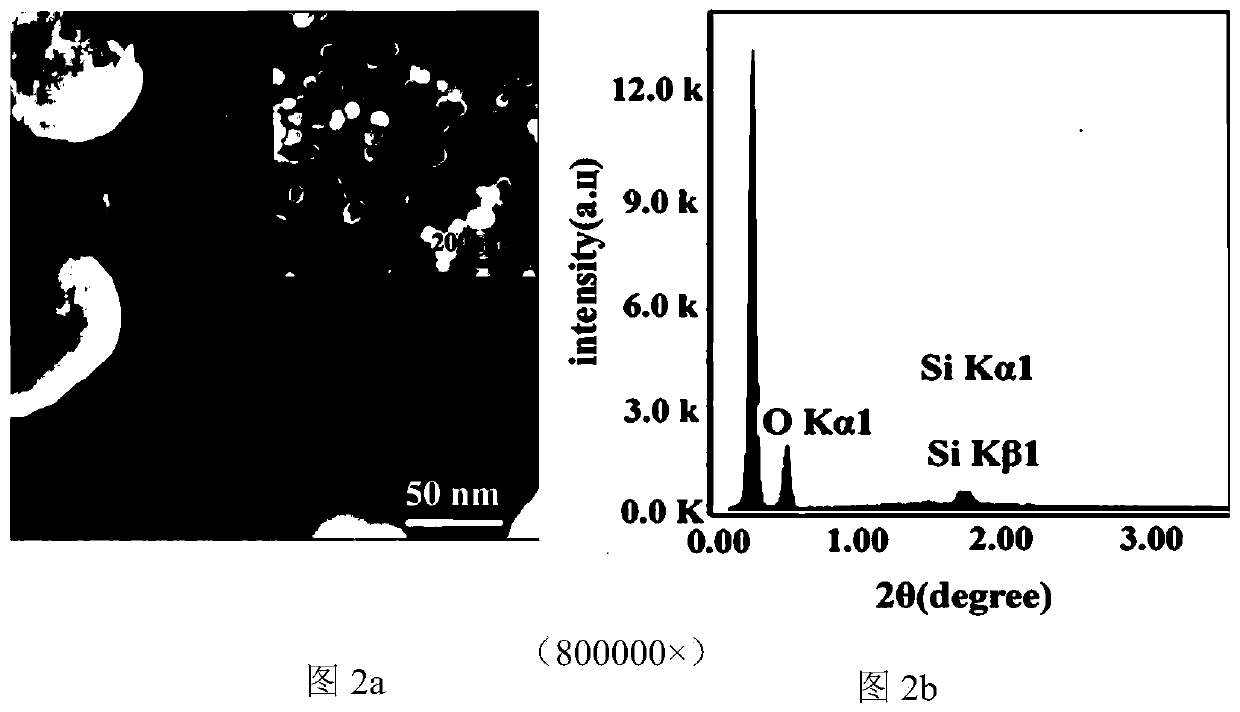

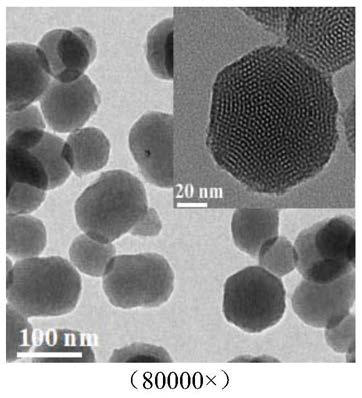

[0046] Step 1. Perform micro-arc oxidation. The parameters of the micro-arc oxidation are set as follows: the frequency of the micro-arc oxidation arc is 100 Hz, the positive pressure is 450 V, and the duty cycle is 26%. In the micro-arc oxidation process, the pure magnesium or magnesium alloy disc is used as the anode, and the stainless steel electrolytic cell is used as the cathode. The composition and concentration of the electrolyte are: NaOH 0.125mol / L, Ca(OH) 2 0.0135mol / L, β-Na2GP 0.02mol / L. During the preparation process, a cooling system was used to control the temperature of the micro-arc oxidation electrolyte at 273K. After the prepared samples were washed with alcohol and deionized water, they were placed in a dry box for later use. Obtain the magnesia coating containing phosphorus and calcium, and its surface SEM photos ...

Embodiment 2

[0056] The preparation method of the active coating with self-healing function on the magnesium-based surface comprises the following steps:

[0057] Step 1. Perform micro-arc oxidation. The parameters of the micro-arc oxidation are set as follows: the frequency of the micro-arc oxidation arc is 100 Hz, the positive pressure is 450 V, and the duty cycle is 26%. In the micro-arc oxidation process, the pure magnesium or magnesium alloy disc is used as the anode, and the stainless steel electrolytic cell is used as the cathode. The composition and concentration of the electrolyte are: NaOH 0.125mol / L, Ca(OH) 2 0.0135mol / L, β-Na2GP 0.02mol / L. During the preparation process, a cooling system was used to control the temperature of the micro-arc oxidation electrolyte at 273K. After the prepared samples were washed with alcohol and deionized water, they were placed in a dry box for later use. Obtain the magnesia coating containing phosphorus and calcium, and its surface SEM photos ...

Embodiment 3

[0067] The preparation method of the active coating with self-healing function on the magnesium-based surface comprises the following steps:

[0068] Step 1. Perform micro-arc oxidation. The parameters of the micro-arc oxidation are set as follows: the frequency of the micro-arc oxidation arc is 100 Hz, the positive pressure is 450 V, and the duty cycle is 26%. In the micro-arc oxidation process, the pure magnesium or magnesium alloy disc is used as the anode, and the stainless steel electrolytic cell is used as the cathode. The composition and concentration of the electrolyte are: NaOH 0.125mol / L, Ca(OH) 2 0.0135mol / L, β-Na2GP 0.02mol / L. During the preparation process, a cooling system was used to control the temperature of the micro-arc oxidation electrolyte at 273K. After the prepared samples were washed with alcohol and deionized water, they were placed in a dry box for later use. Obtain the magnesia coating containing phosphorus and calcium, and its surface SEM photos ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com