Continuous crushing recovery treatment method for construction waste

A technology for recycling and processing construction waste, which is applied to special forming/shaping machines, forming/shaping machines, multi-purpose machinery, etc., can solve the problems of construction wastes that bother developers and restrict the scope of recycling and reuse, and achieve ingenious structure , The effect of simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

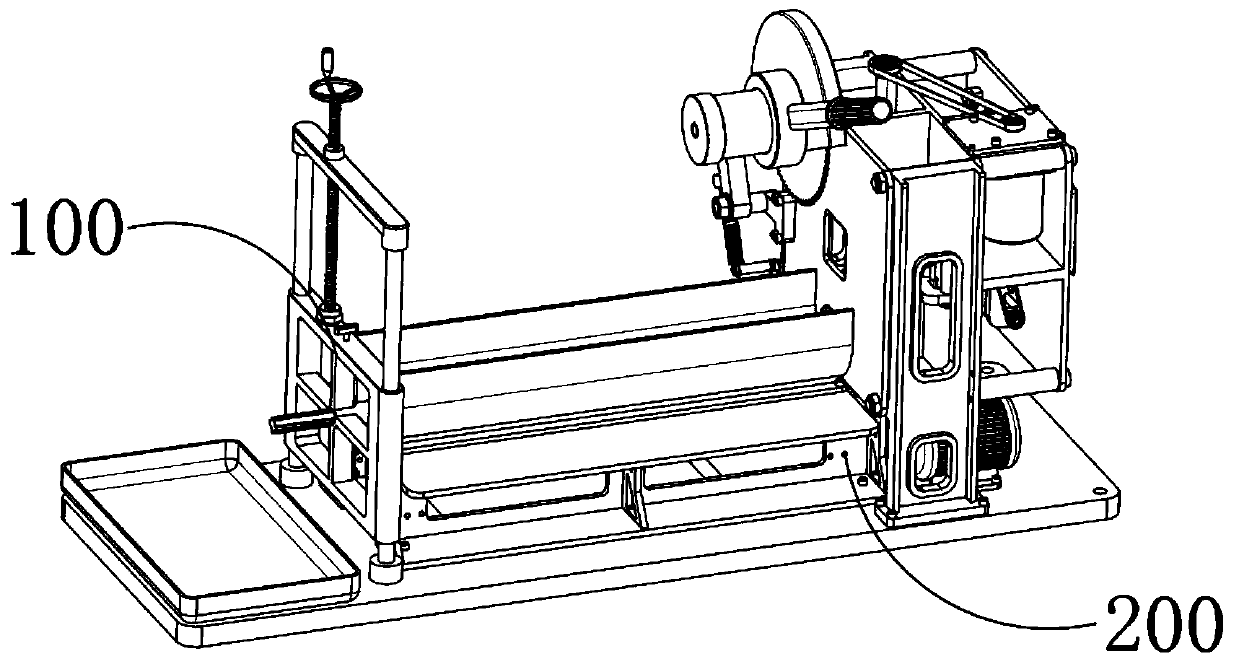

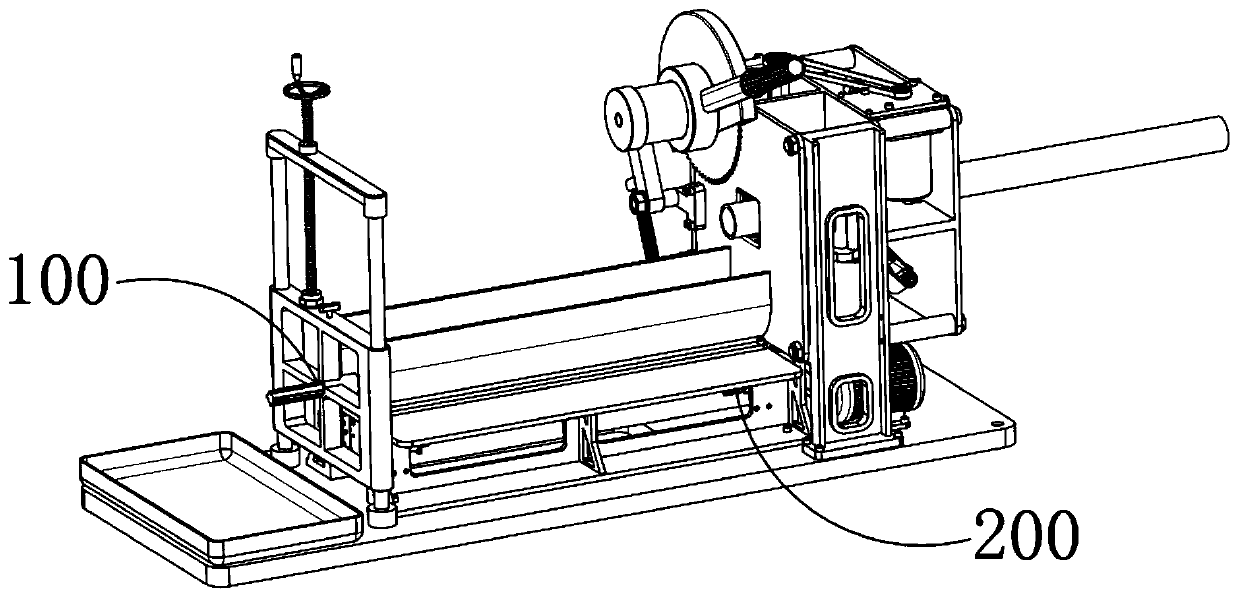

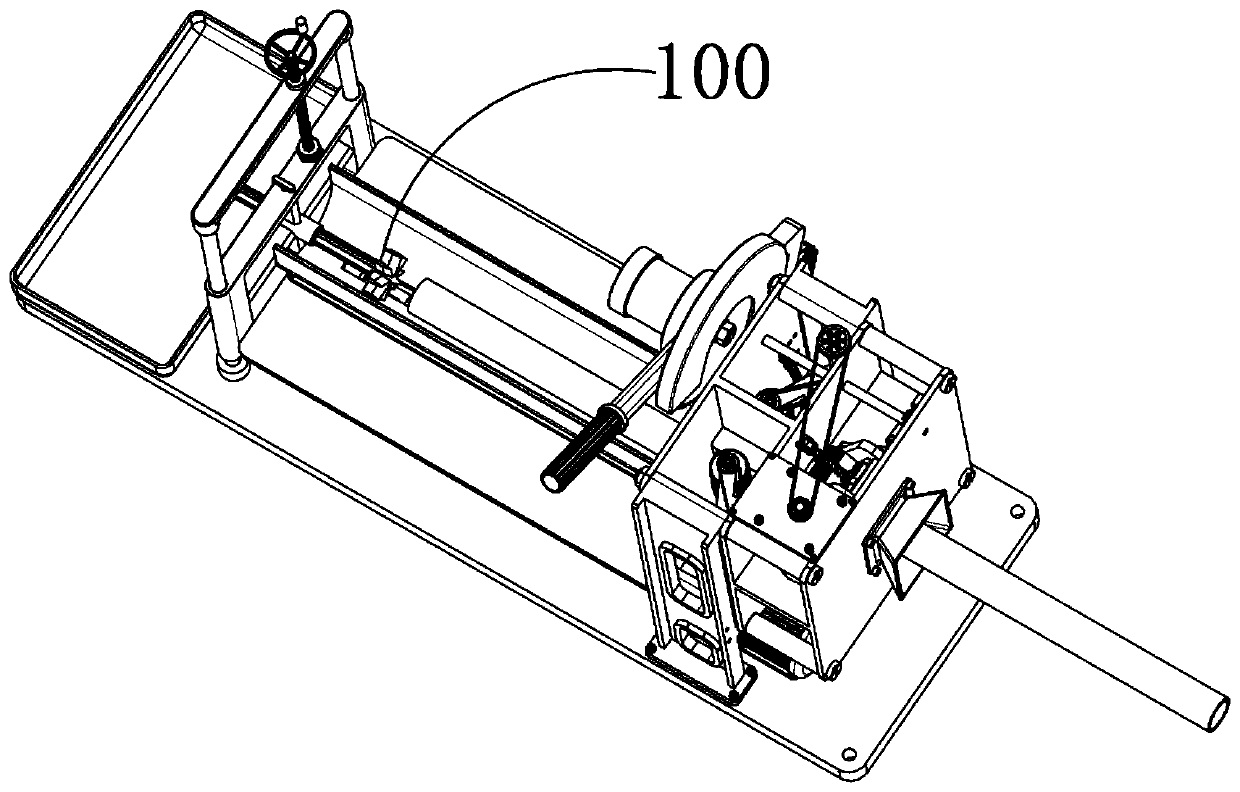

Image

Examples

Embodiment Construction

[0056] The method for continuous crushing and recycling of construction waste comprises the following steps:

[0057] (1) Feeding and cutting stage;

[0058] S1: The user inserts bamboo and other wood bars into the feeding port of the feeding mechanism 110, and the feeding mechanism 110 pushes the inserted bamboo and other wood bars to the top of the collection chamber 140;

[0059] During the feeding process, the user inserts bamboo and other wood bars into the feeding port, and the horizontal roller member clamps and transports the bamboo and other wood bars in the vertical direction, and the vertical roller member holds the bamboo and other wood bars in the horizontal direction. Carry out positive transport of the limit clip in the direction, so that the wood bars such as bamboo are discharged from the discharge port;

[0060] S2: The cutting mechanism 130 cuts the wood bars such as bamboo located above the collection cabin 140 and controls the length of the cut, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com