Temperature self-adjusting injection punch head

A self-adjusting technology for injection punches, applied in the field of temperature self-adjusting injection punches, can solve the problems of increased friction, scratches, uneven temperature distribution and thermal deformation of injection punches and injection chambers, and achieve saving Cost of use, increased service life, safety and economical advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

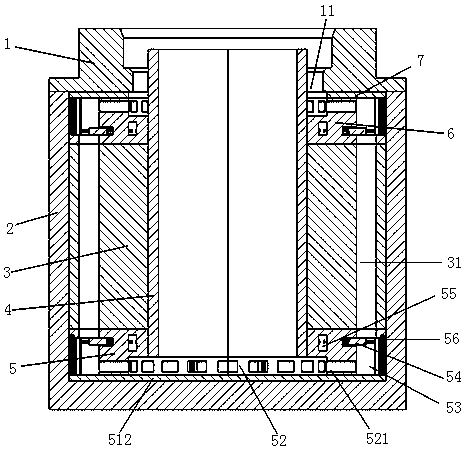

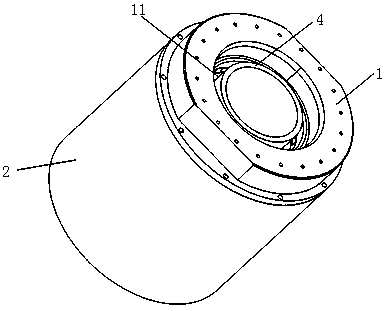

[0026] Such as Figure 1-3 As shown, a temperature self-adjusting injection punch of the present invention includes a punch base 1, a punch shell 2 and a punch body 3 installed on the punch base 1, and the center of the punch base 1 and the punch body 3 A cooling water inlet pipe 4 is provided on the top, and a plurality of cooling branch pipelines 31 are evenly distributed around. There is a water inlet flow regulating mechanism 5 , the punch housing 2 is set on the punch body 3 and the water inlet flow regulating mechanism 5 and is fixedly connected with the punch base 1 .

[0027] Such as Figure 4 As shown, the punch base 1 is composed of an interface 11 and a base 12, and the interface 11 and the base 12 have a hole in the center for the cooling water inlet pipe 4 to pass through. The interface 11 has threads 13 for connecting the injection rod; the base 12 has circumferentially uniform threaded holes 14 for installing the beryllium copper shell 2 of the punch.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com