High efficient and environmental friendly ore crusher for mining capable of adjusting sizes of particles

A particulate matter and adjustable technology, applied in grain processing and other directions, can solve the problems of no feeding device, blockage of ore equipment, occupying a large space, etc., and achieve the effect of small space occupation, space saving and safety improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

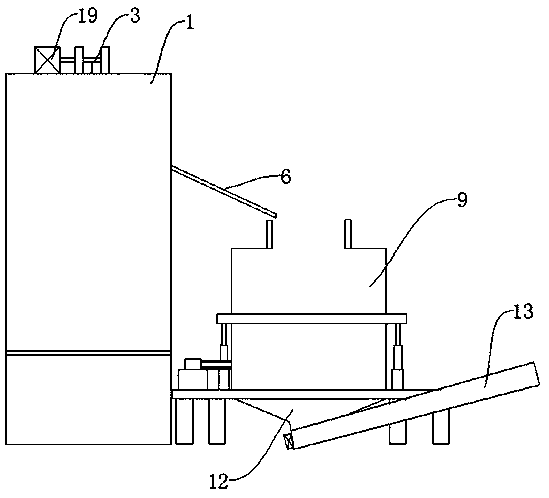

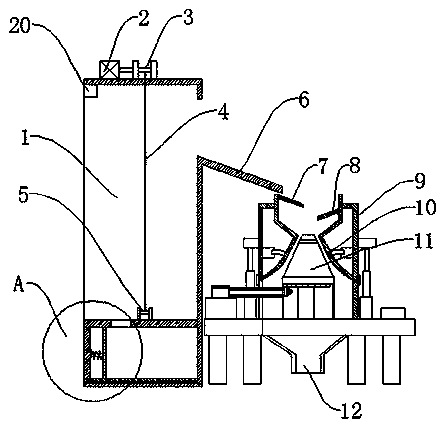

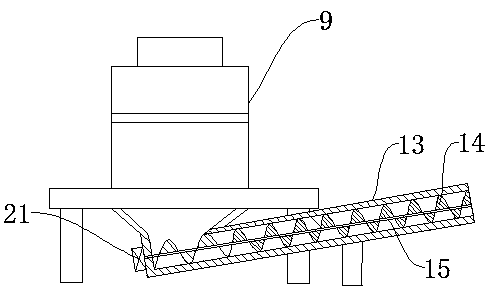

[0031] refer to Figure 1-4 , a high-efficiency and environmentally friendly mining ore crusher with adjustable particle size, comprising a feeding bracket 1, a crushing device 9 and a material receiving device, the feeding bracket 1 is connected to the top of the crushing device 9, and the material receiving device is connected to the bottom of the crushing device 9, The crushing device 9 includes an upper body and a lower body. The upper body is connected with a hopper and a fixed liner 10, the lower body is connected with a floating bush 11, and the bottom of the floating bush 11 is connected with an eccentric shaft. The bottom is connected with a discharge bin 12; the high-efficiency ore crusher with adjustable particle size can easily send large pieces of ore to the hopper for processing through the three-dimensional feeding bracket 1, and at the same time, the three-dimensional feeding bracket 1 and the transmission device Compared with it, it takes up less space and sav...

Embodiment 2

[0033] refer to Figure 1-2 , a high-efficiency and environmentally-friendly mining ore crusher with adjustable particle size, which is basically the same as Embodiment 1. Further, the top of the feeding bracket 1 is connected to a horizontal plate, and the top of the horizontal plate is connected to a first motor 2, and the first motor 2 The output end is rotatably connected with a rotating shaft 3, the outer wall of the rotating shaft 3 is connected with a cable 4, the end of the cable 4 away from the rotating shaft 3 passes through the horizontal plate and is connected with a connecting rod 5, the feeding bracket 1 is connected with a material box, and the top of the material box is provided with a The feeding port is connected with a propulsion mechanism in the feed box, and the top of the feed box is connected with two identical vertical plates, the connecting rod 5 is connected between the two vertical plates, and the top inner wall of the feeding bracket 1 is connected w...

Embodiment 3

[0035] refer to Figure 1-4 , a high-efficiency and environmentally friendly mining ore crusher with adjustable particle size is basically the same as Embodiment 1. Further, the propulsion mechanism includes a fixed plate 16, and the side wall of the fixed plate 16 is connected with a telescopic rod 19. The telescopic rod 19 is far away from the fixed One end of the plate 16 is connected with a push plate 17, and the outer wall of the expansion rod 19 is sleeved with a spring 18, and the spring 18 is fixedly connected between the fixed plate 16 and the push plate 17; The telescopic rod 19 telescopically will push the push plate 17 outwards, thereby the ore in the feed box is pushed out, and the telescopic rod 19 can be automatically reset after the motion by the spring 18, which is convenient for repeated use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com