Air atomization nozzle of double-oil-path and double-rotational-flow structure

An air atomization and double-swirl technology, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve the problems of poor fuel atomization quality, small fuel pressure difference, low combustion efficiency of combustion chamber, etc., to improve fuel speed , reduce emissions and improve combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

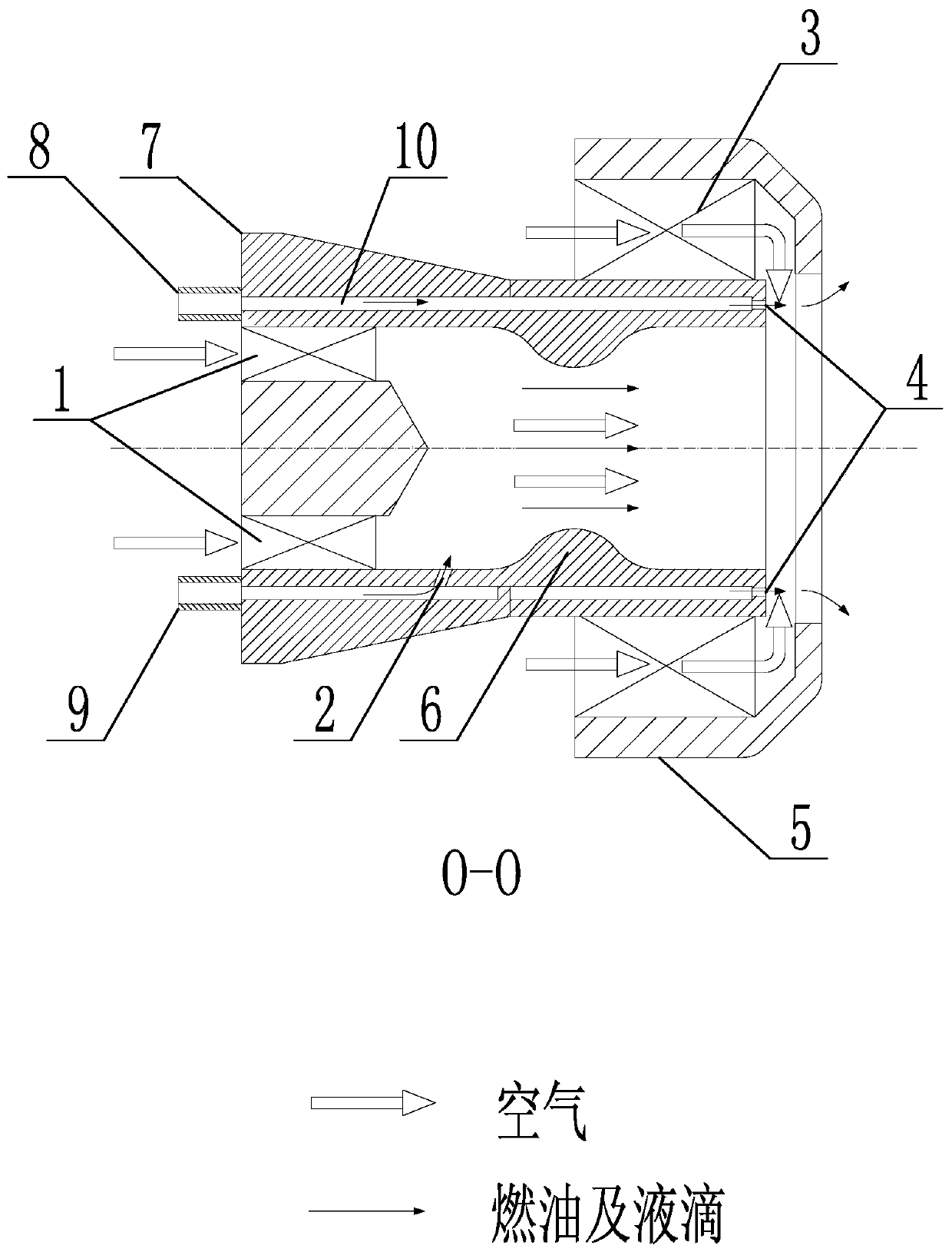

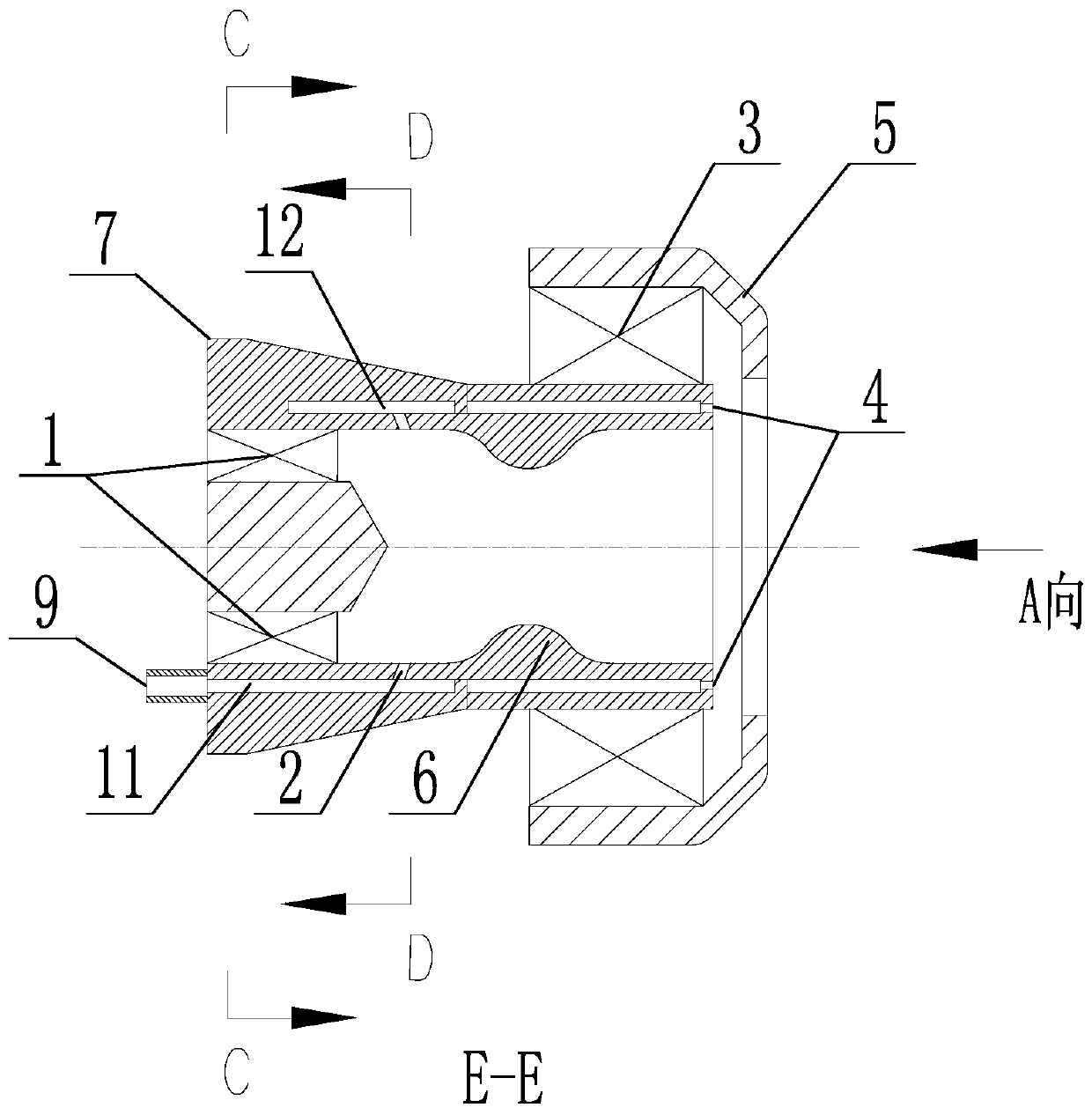

[0030] Such as figure 2 , image 3 and Figure 8 As shown, the air atomizing nozzle includes a primary cyclone 1, a secondary cyclone 3, a flow sleeve 5 and a nozzle body 7, and the primary cyclone 1 and the secondary cyclone 3 are axial Cyclone, the primary cyclone 1 is fixedly installed in the inlet of the nozzle body 7 (that is, the upstream position of the nozzle body), and the secondary cyclone 3 is set on the nozzle end of the nozzle body 7 (that is, the downstream position of the nozzle body) ;

[0031] Such as figure 2 , image 3 and Figure 7 As shown, the diversion sleeve 5 is a sleeve with openings at both ends, one end of the diversion sleeve 5 is sleeved on the outside of the secondary cyclone 3, and the other end of the diversion sleeve 5 is bent inwards and placed in a On the outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com