Electric control VE dispensing pump for directly measuring advance angle by inductance type transducer

A technology of inductive sensors and distribution pumps, which is applied in the direction of machines/engines, engine components, charging systems, etc., can solve problems such as the inability to realize the electronic control of VE distribution pumps, and achieve saving development costs and time, low prices, and increased cams lift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

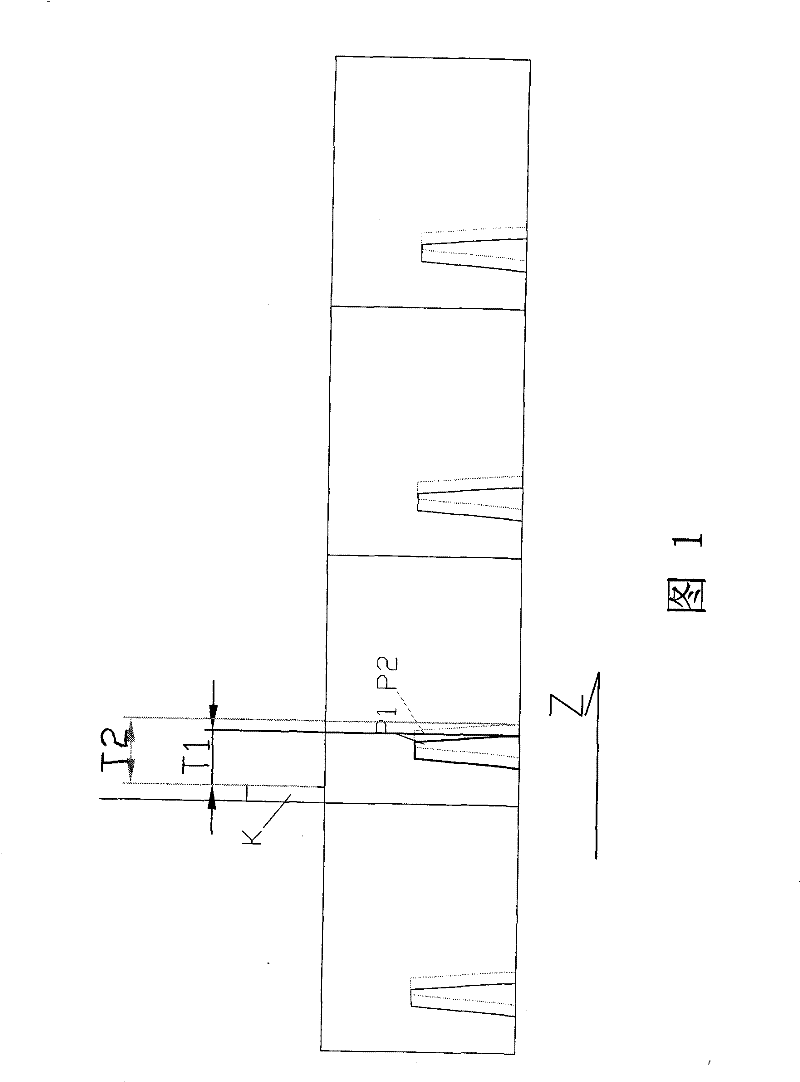

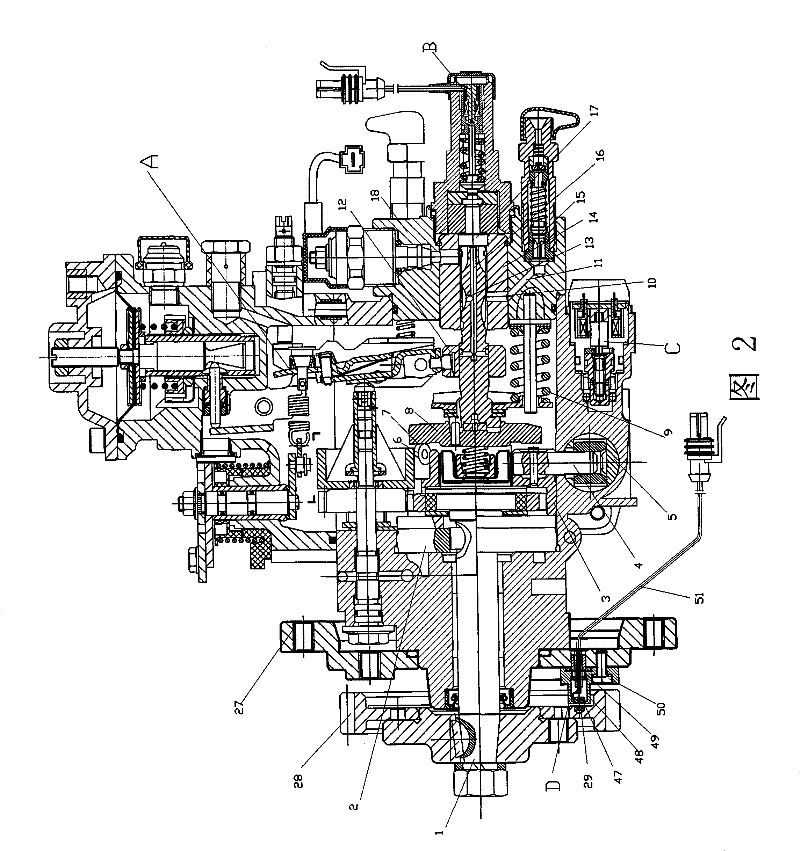

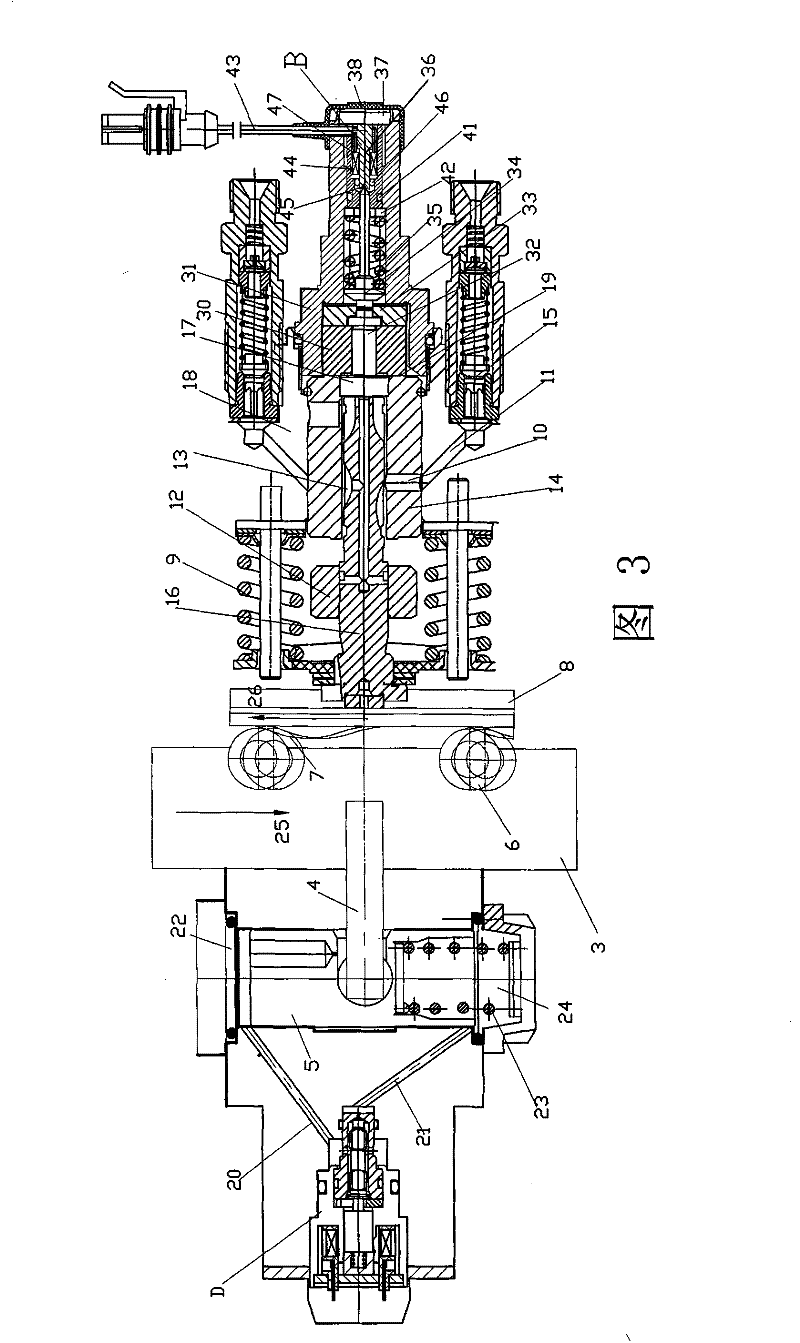

[0012] like figure 1 , 2 As shown, an inductive advance angle sensor B is installed at the front end of the distribution housing 18 of the mechanical speed-adjustable VE distribution pump A, an advancer piston 5 and a high-speed solenoid valve C are installed at the bottom of the oil pump, and a top stop is installed on the distribution pump mounting plate 27. point sensor D. The mechanical governor is used to control the position of the control sleeve and adjust the oil supply of the oil pump. The fuel supply advance angle is directly controlled by the electronic control unit ECU through the high-speed solenoid valve C, and the inductive advance angle sensor B and the top dead center sensor D provide closed-loop control signals to directly control the fuel supply advance angle.

[0013] The structure and working principle of the top dead center signal sensor D are as follows: the top dead center signal sensor D is a sensor equipped with a Hall inductive element. The Hall i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com