Burning ultra-thick oil by method of rotating cup atomization

A rotary cup atomization and ultra-heavy oil technology, applied in the combustion method, burner, combustion type and other directions, can solve the problems of high temperature gasification maintenance, insufficient combustion, increased cost, etc., and achieve low exhaust temperature and atomization. Good effect and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

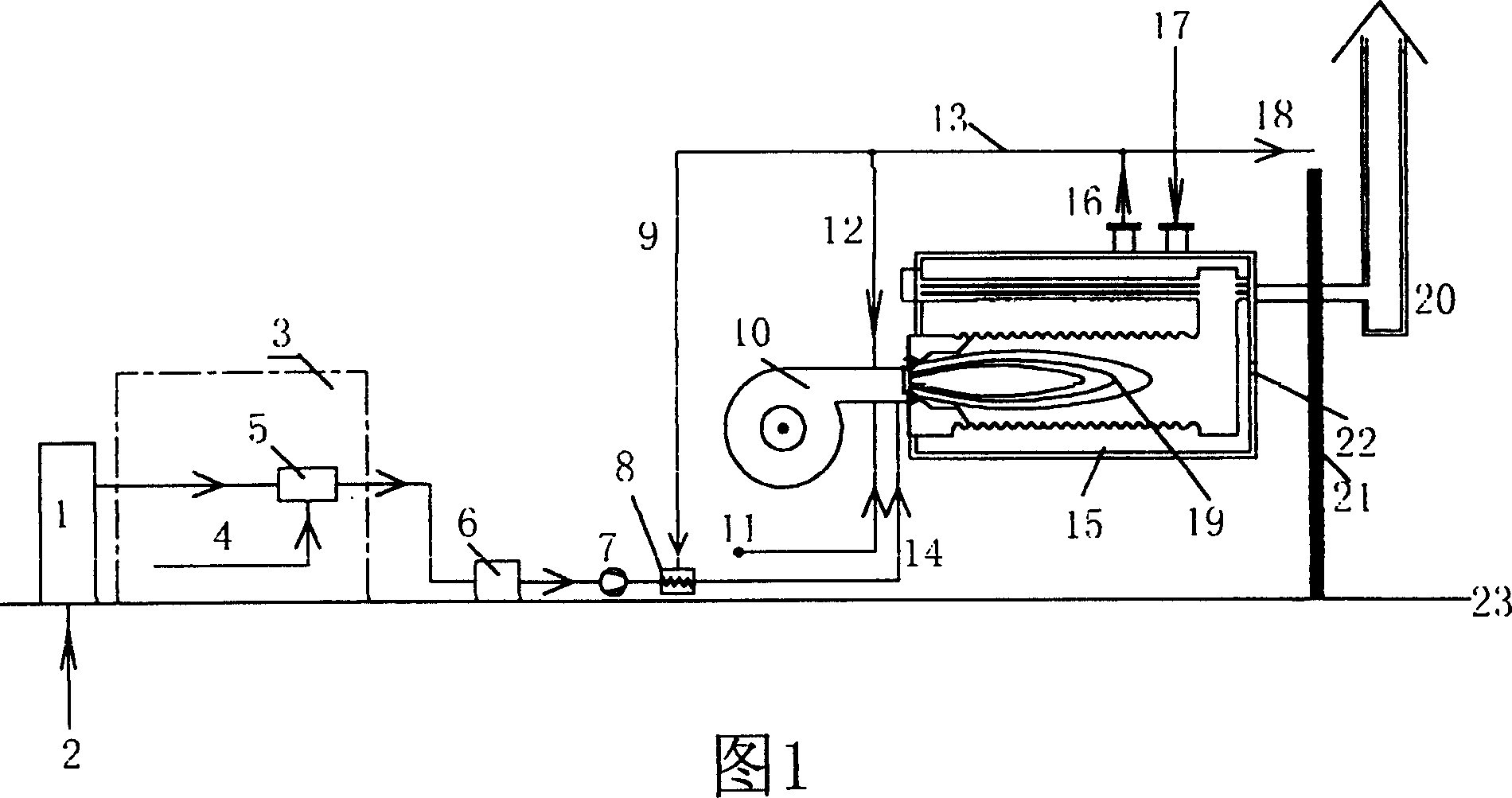

[0027] What accompanying drawing 1 has described is steam-assisted pressure atomization combustion mode. In the accompanying drawing 1, after the underground super heavy oil 2 is extracted from the oil well, it is temporarily stored by the oil storage tank 1, and then transported to the emulsification plant 3, and the emulsifier 4 is added in the emulsification device 5, and the emulsified oil 6 is synthesized. The pumping station 7, heater 8, and oil supply system 14 enter the pressure burner 10, generate an unadjustable flame 19 and enter the boiler body 15, and the steam 18 produced is used for production, and part of the steam 12 is used for auxiliary emulsified oil or The mixed oil is atomized and burned.

[0028] Note 1 in Figure 1 is super heavy oil storage tank, 2 is underground super heavy oil, 3 is emulsification plant, 4 is emulsifier, 5 is emulsification device, 6 is emulsified oil, 7 is pumping station, 8 is heater , 9 is heating steam, 10 is pressure burner, 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com