Epoxy-cured 70:30 polyester resin with excellent leveling property and solvent resistance and preparation method thereof

A polyester resin and solvent-resistant technology, applied in epoxy resin coatings, polyester coatings, powder coatings, etc. Problems such as leveling on the surface of the film, to achieve the effect of high cross-linking density, excellent leveling, and prolonging the gelation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

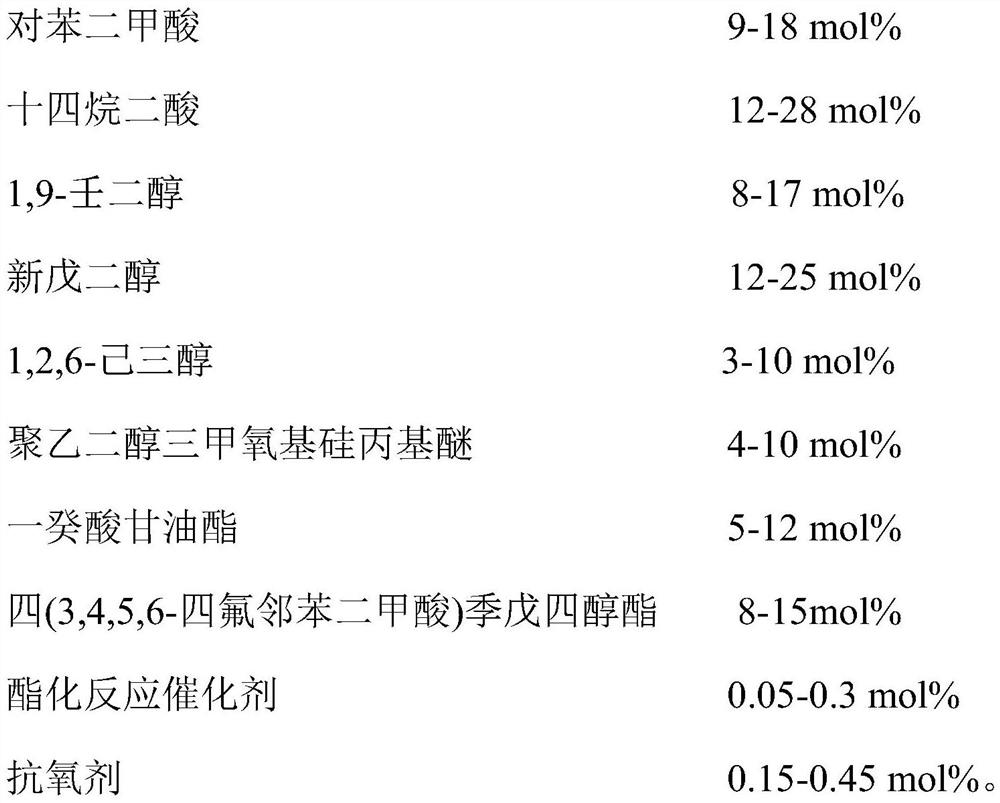

[0032] An epoxy-cured 70:30 polyester resin with excellent leveling properties and solvent resistance, its raw material composition and molar ratio are:

[0033]

[0034]

[0035] A method for preparing the excellent epoxy curing 70:30 polyester resin of above-mentioned leveling property and solvent resistance, comprising the following steps:

[0036] A. Add the formulated amount of 1,9-nonanediol, neopentyl glycol and 1,2,6-hexanetriol into the reaction kettle, heat and melt below 125°C, stir and mix evenly;

[0037]B. Add the formulated amount of terephthalic acid and catalyst to the above mixture, slowly raise the temperature to 170°C at a heating rate of 5°C / h and keep it warm for 2 hours. When the esterification water is not obvious, start the vacuum and keep the vacuum degree at React for 2 hours under the condition of 70mmHg, then remove the vacuum, add the formulated amount of tetradecanedioic acid, polyethylene glycol trimethoxysilyl propyl ether and glyceryl mo...

Embodiment 2

[0042] An epoxy-cured 70:30 polyester resin with excellent leveling properties and solvent resistance and a preparation method thereof, the raw material composition and molar ratio are:

[0043]

[0044] Its preparation method etc. are the same as embodiment 1.

[0045] The acid value of the prepared polyester resin is: 31 mgKOH / g, and the melt viscosity (200° C.): 4075 mPa·s.

Embodiment 3

[0047] An epoxy-cured 70:30 polyester resin with excellent leveling properties and solvent resistance and a preparation method thereof, the raw material composition and molar ratio are:

[0048]

[0049]

[0050] Its preparation method etc. are the same as embodiment 1.

[0051] The acid value of the prepared polyester resin is: 38 mgKOH / g, and the melt viscosity (200° C.): 3820 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com