Power plant waste water evaporation treatment method and waste water evaporation treatment system thereof

A treatment method and technology for power plant wastewater, applied in the field of water treatment, can solve the problems of intractable wastewater treatment, large energy consumption, large operation, treatment and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

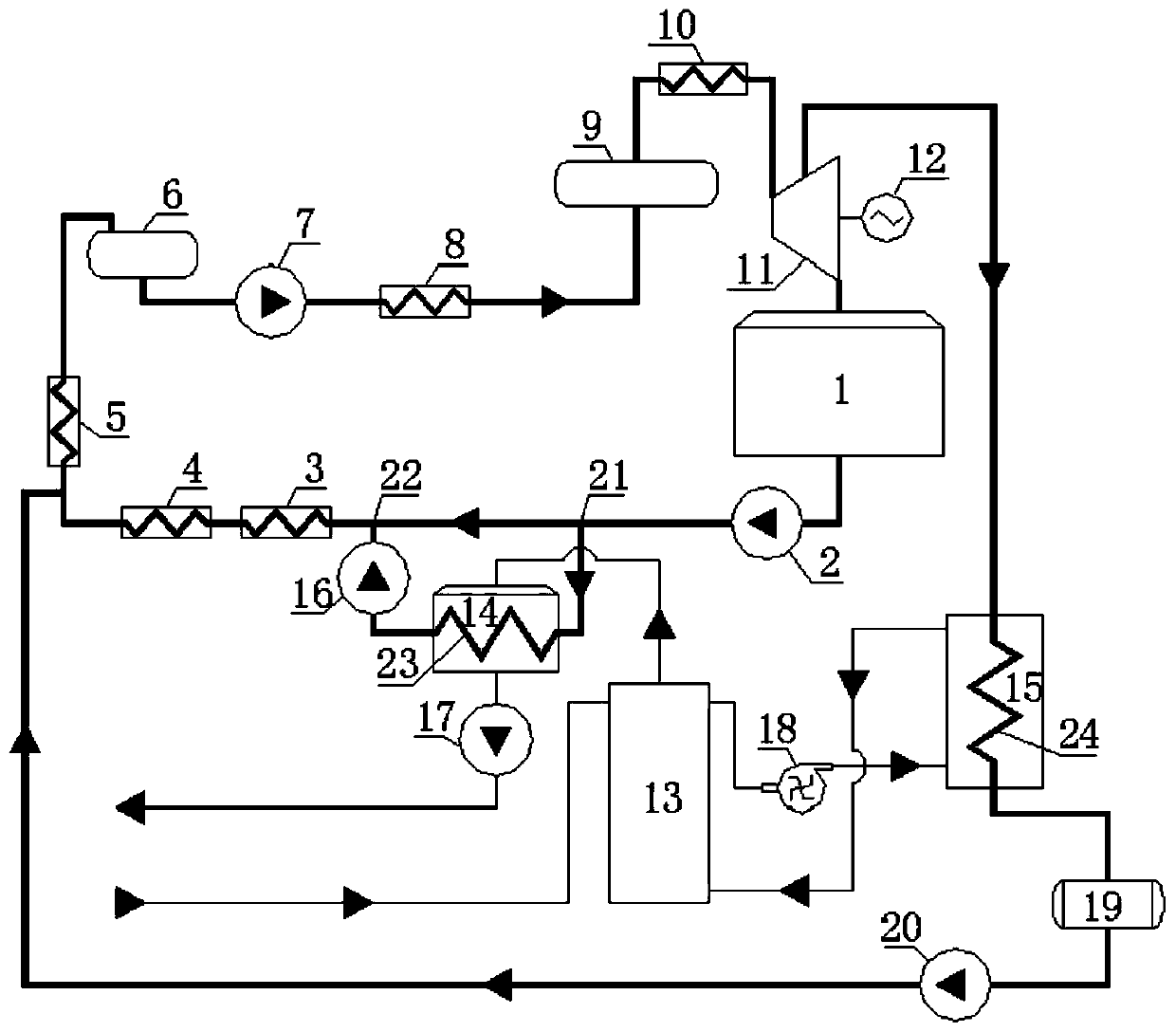

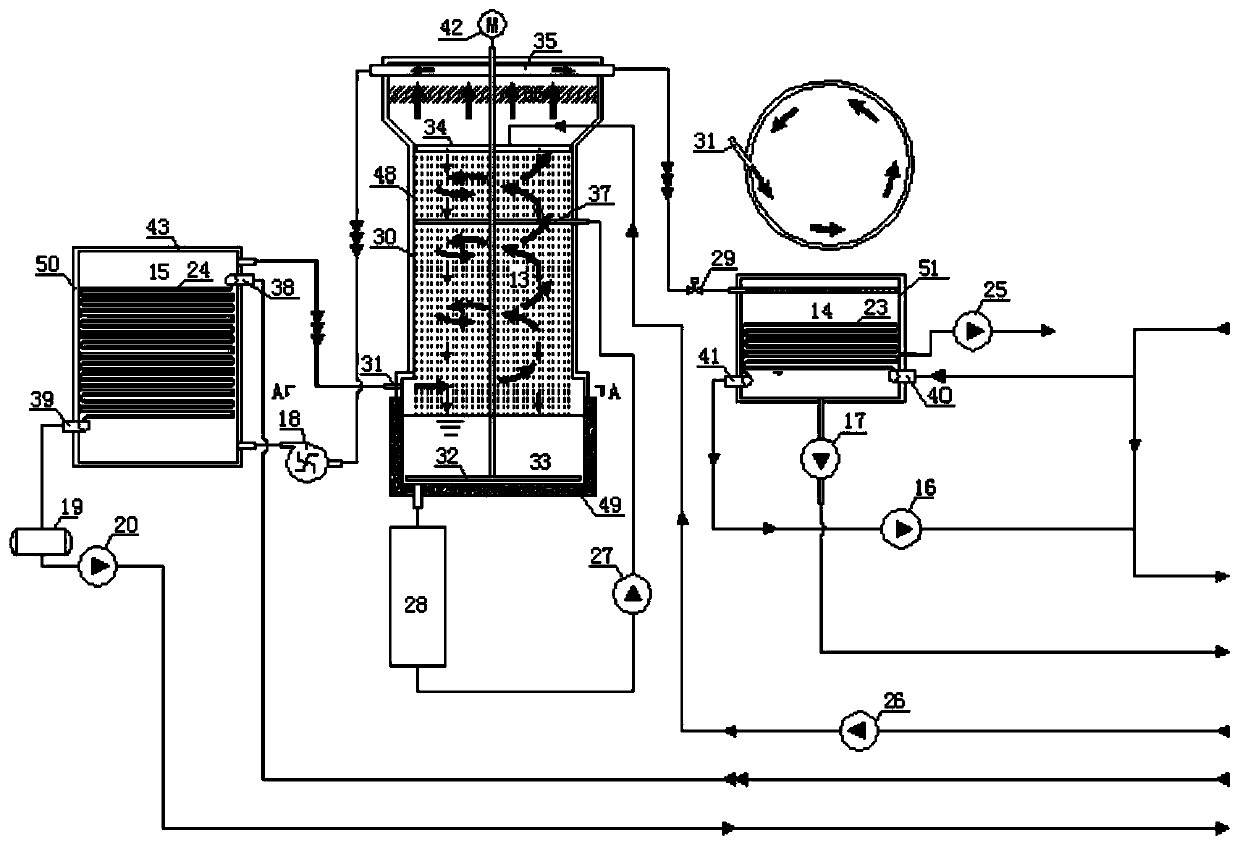

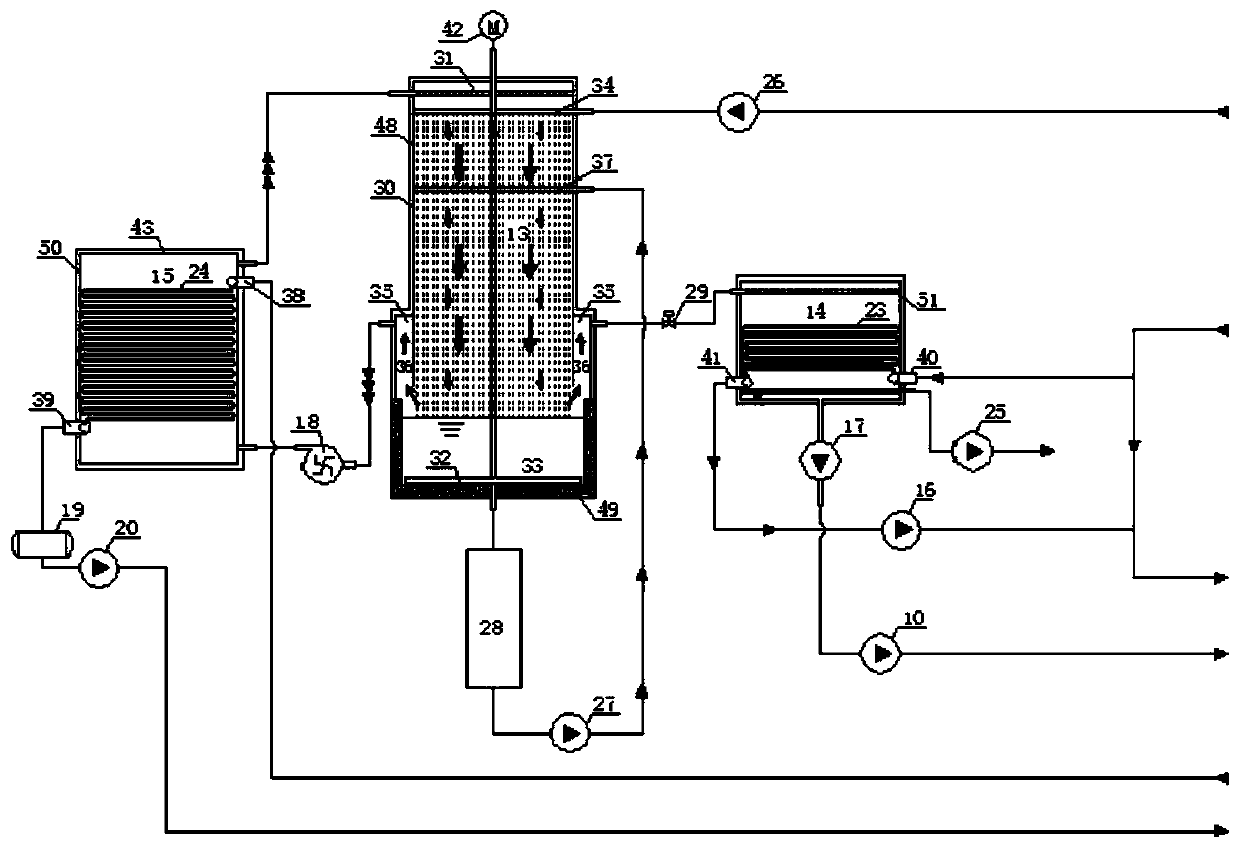

[0033] A method for evaporating power plant wastewater, including a wastewater evaporator, a condenser, and a heat transfer medium heater. Part of the water vapor from the wastewater evaporator is sent to the condenser to condense into water, and the other part of the water vapor is collected and sent to the heat transfer medium. After the medium heater is heated, it returns to the waste water evaporator to heat and evaporate the waste water; the heat source of the heat transfer medium heater comes from the main steam of the steam turbine or the high-temperature steam extracted from the heat recovery system; the cold source of the condenser comes from the condensed water of the steam turbine Condensate at lower system temperatures.

[0034]The process of the heat source is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com