Assembling method of square winding type lithium ion battery and lithium ion battery

A lithium-ion battery and assembly method technology, which is applied to secondary batteries, secondary battery manufacturing, battery pack components, etc., can solve the problems of high proportion of blank space, low production efficiency, and high process loss, etc., and achieve improved battery performance. Increased energy density, effective use of space, and improved battery energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] Embodiment 1 (single winding core lithium-ion battery assembly process)

[0121] A method for assembling a square wound lithium-ion battery, comprising the following steps:

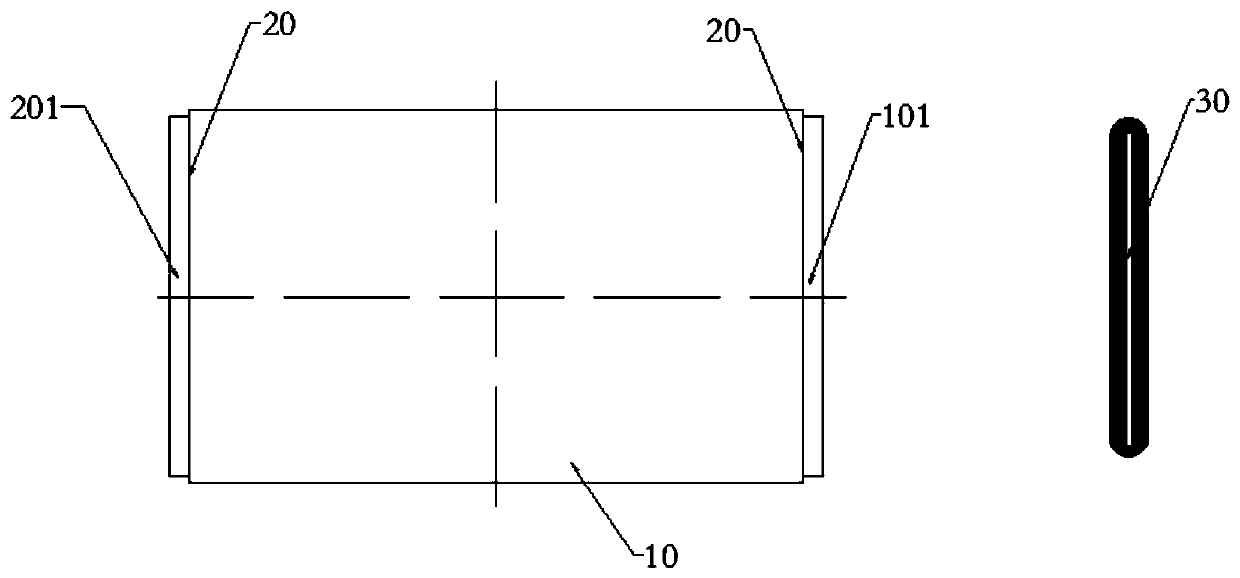

[0122] (1) Core shaping: The rolled core is first heat-pressed by a hot press, the temperature is controlled at 80°C, the time is controlled at 60s, and the pressure of the core is 5MPa; then it is cold-pressed with a cold press, and the temperature is controlled at 20°C, the time is controlled at 60s, and the core pressure is 0.5MPa; the core after shaping is as follows figure 1 shown;

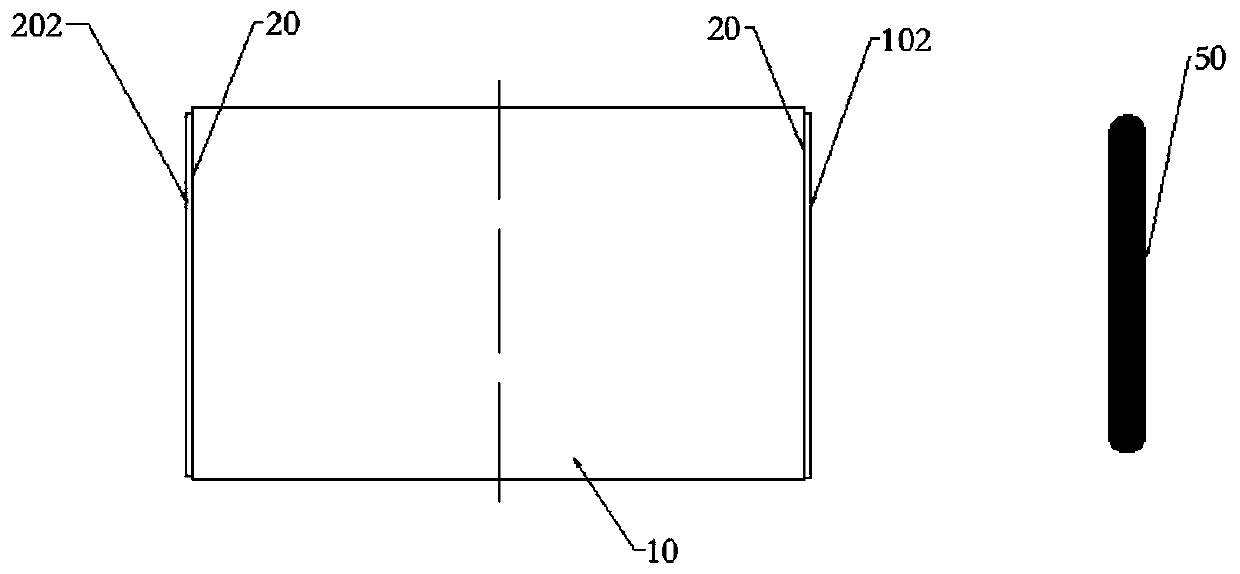

[0123] (2) Knead flat: Use a super-smooth kneading machine to knead the positive and negative blank areas of the winding core flat, kneading is to knead all the blank areas flat, and the kneading depth is 2mm; the effect after kneading like figure 2 shown;

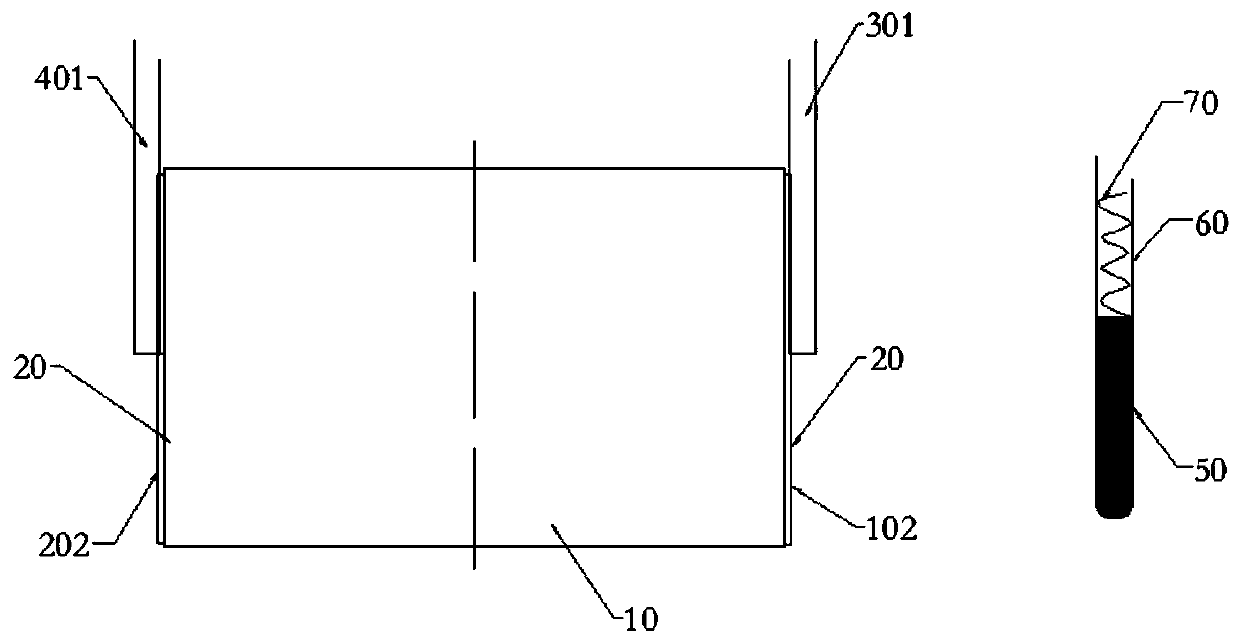

[0124] (3) Welding: Weld the positive bus bar and the positive cover plate together, weld the negative bus bar and the negative cover plate together, and...

Embodiment 2

[0127] Embodiment 2 (assembly process of single winding core lithium ion battery)

[0128] A method for assembling a square wound lithium-ion battery, the difference from Example 1 is:

[0129] (1) Core shaping: The rolled core is first heat-pressed by a hot press, the temperature is controlled at 100°C, the time is controlled at 120s, and the pressure of the core is 10MPa; then it is cold-pressed with a cold press, and the temperature is controlled at 30°C, the time is controlled at 100s, and the winding core pressure is 1MPa;

[0130](2) Flattening: use mechanical vibration and flattening equipment to flatten the positive and negative blank areas of the winding core. Kneading is to flatten part of the blank area. The white area, the kneading depth is 4mm; the effect after kneading is as follows Figure 4 shown;

[0131] (3) Welding: Weld the positive bus bar and the positive cover plate together, weld the negative bus bar and the negative cover plate together, and then la...

Embodiment 3

[0132] Embodiment 3 (single winding core lithium-ion battery assembly process)

[0133] A method for assembling a square wound lithium-ion battery, the difference from Example 1 is:

[0134] (1) Core shaping: The rolled core is first heat-pressed by a hot press, the temperature is controlled at 70°C, the time is controlled at 30s, and the pressure of the core is 0.2MPa; then it is cold-pressed with a cold press and the temperature is controlled. At 25°C, the time is controlled at 30s, and the winding core pressure is 0.1MPa;

[0135] (2) Kneading: use an ultrasonic kneading machine to knead the positive and negative blank areas of the winding core. Kneading is to knead part of the blank area, and the kneading area and the blank area are set alternately. The kneading depth is 1mm; the effect after kneading is as follows Image 6 shown;

[0136] (3) Welding: Weld the positive bus bar and the positive cover plate together, weld the negative bus bar and the negative cover plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com