ESD smart spot check system and application thereof

A point inspection system, intelligent technology, applied in the direction of instruments, measuring devices, measuring electricity, etc., can solve the problems of operator point inspection errors and omissions, cumbersome, no anti-static wristband protection resistance detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings.

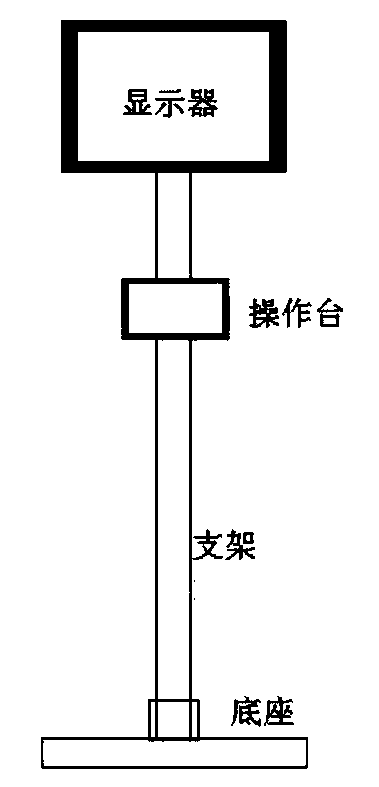

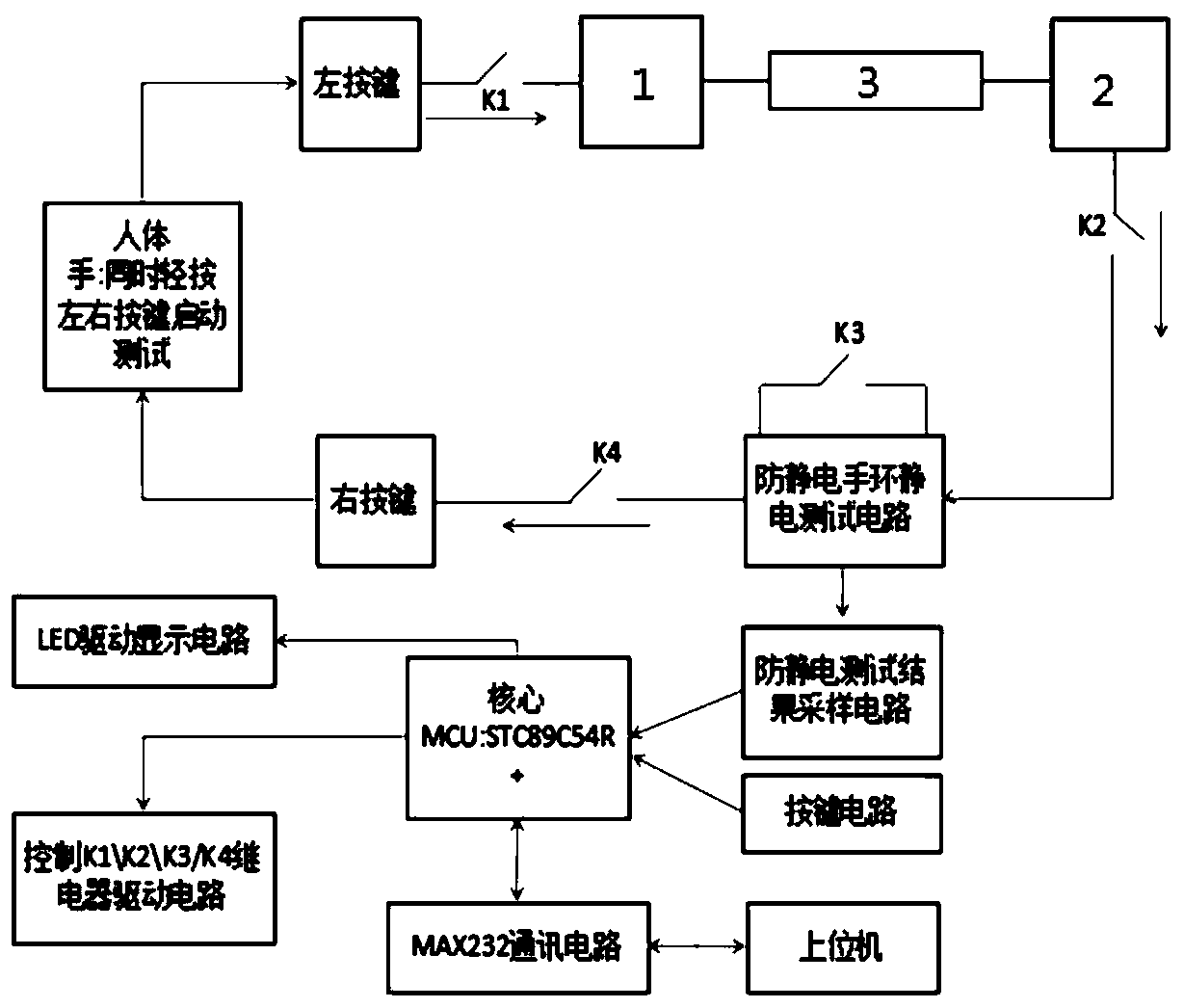

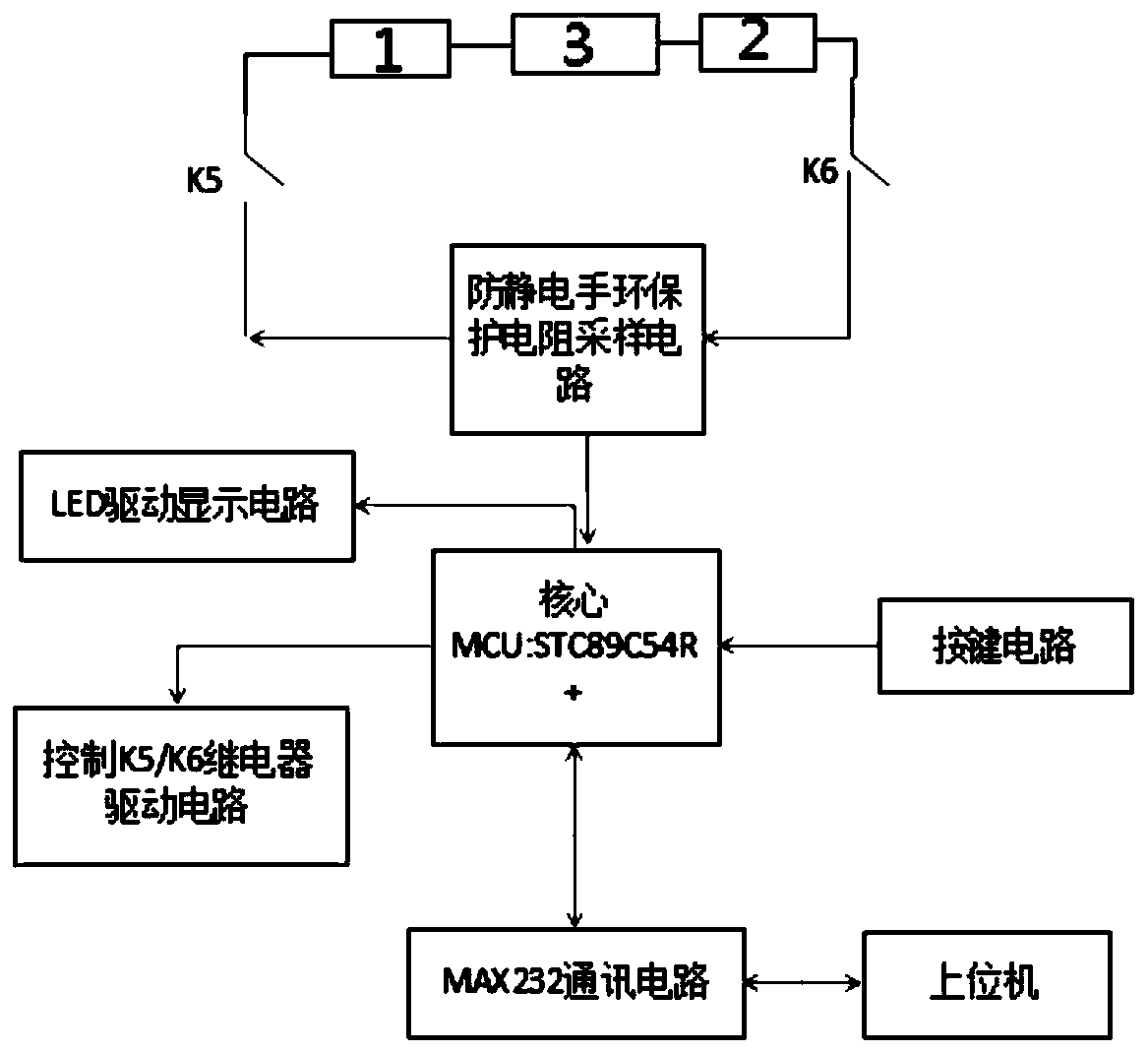

[0073] as attached figure 1 As shown, the hardware part of the present invention consists of a base, a bracket, an operating table, and a display to form an overall spot inspection structure. Compared with traditional equipment, the structure is simpler, and at the same time, it is incorporated into the "fingerprint collection area" to match the associated operators in the system to prevent operator Omission of personnel inspection; easy operation, the operator only needs to stand on the base metal pedal, attach one end of the anti-static wristband to the "wrist strap magnetic attraction", and insert the other end into the "grounding rubber jack". Simply click the left and right buttons in the sensing area, which greatly reduces unnecessary personnel operations until the end of the test; the "system test selection area" is compatible with both stand-alone and system t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com