High-performance metal reflecting type heat preservation layer

A metal reflective, high-performance technology, applied in thermal insulation, reactors, nuclear power generation, etc., can solve the problems of endangering the health of construction personnel, easy generation of dust, radiation, adverse effects of the surrounding environment, etc., to reduce the hazards of operators and maintenance personnel , good shock resistance and impact resistance, and shorten the time for maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

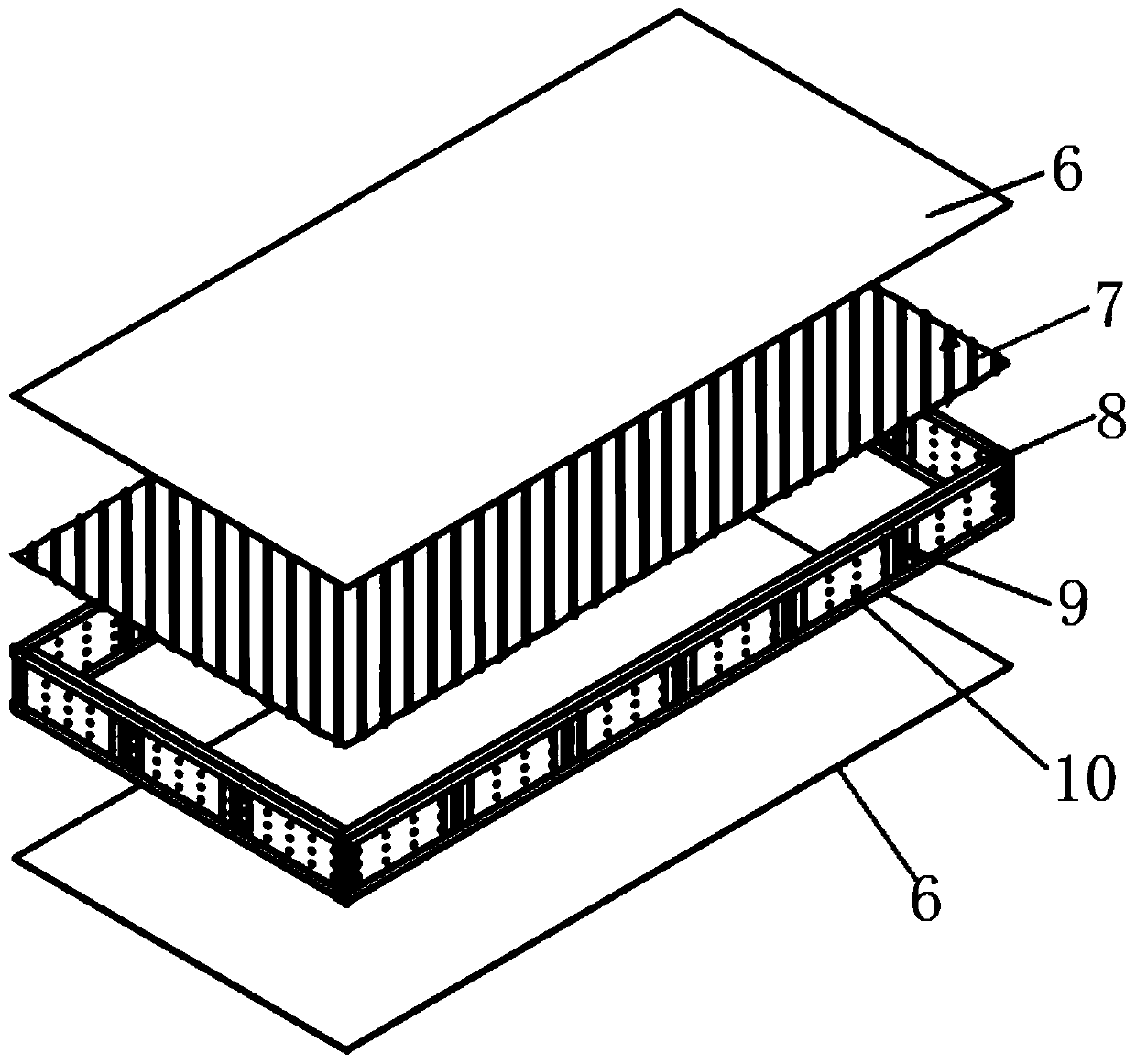

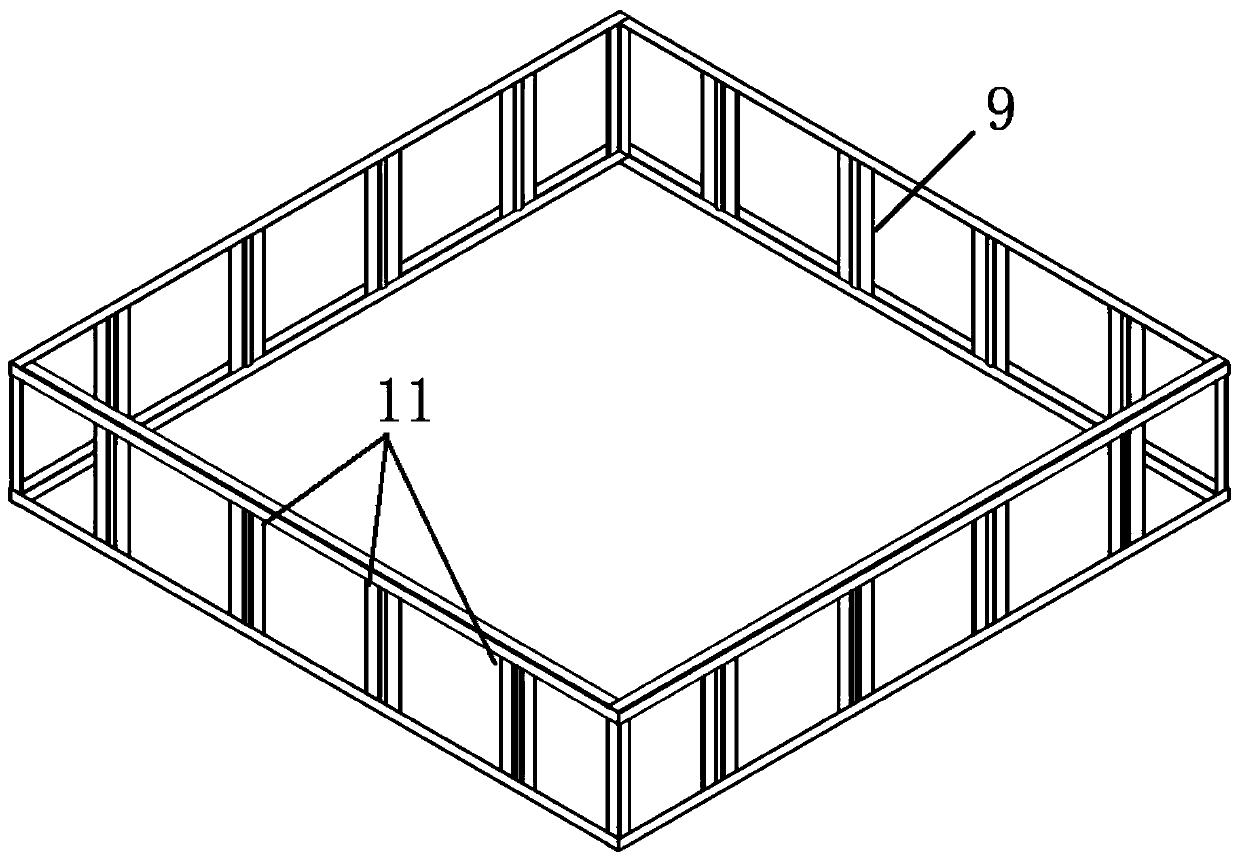

[0036] Such as figure 1 As shown, a high-performance metal reflective insulation layer is composed of three high-performance metal reflective insulation blocks 1, and the connection seams of each high-performance metal reflective insulation block 1 are covered with lap joints 5 to play a role of resistance. Thermal effect; the splicing is a direct splicing, and each high-performance metal reflective insulation block 1 is provided with a corresponding handle 2 and a nameplate 3, the handle 2 is used to install and carry the high-performance metal reflective insulation block 1, and the nameplate 3 is used for Identify the position information of the high-performance metal reflective type insulation block 1.

[0037] The connecting joint connecting the seam is a detachable connection, and the detachable connection adopts the lock buckle 4 to connect, and the lock buckle 4 is a quick-release lock; further, the quick-release lock has a quick-open function and a self-locking functio...

Embodiment 2

[0046] Such as figure 1 As shown, a high-performance metal reflective insulation layer is composed of three high-performance metal reflective insulation blocks 1, and the connection seams of each high-performance metal reflective insulation block 1 are covered with lap joints 5 to play a role of resistance. Thermal effect; the splicing part is a step surface splicing, and each high-performance metal reflective insulation block 1 is provided with a corresponding handle 2 and nameplate 3, and the handle 2 is used for installing and carrying the high-performance metal reflective insulation block 1 and the nameplate 3 It is used to identify the position information of the high-performance metal reflective insulation block 1.

[0047] The connecting joints connecting the seams are non-detachable connections, and the non-detachable connections are connected by spot welding joints 13 .

[0048] Further, the handle 2 can be held by hand, and can be automatically folded when not in us...

Embodiment 3

[0056] Such as figure 1 As shown, a high-performance metal reflective insulation layer is composed of three high-performance metal reflective insulation blocks 1, and the connection seams of each high-performance metal reflective insulation block 1 are covered with lap joints 5 to play a role of resistance. Thermal effect; the splicing is a direct splicing, and each high-performance metal reflective insulation block 1 is provided with a corresponding handle 2 and a nameplate 3, the handle 2 is used to install and carry the high-performance metal reflective insulation block 1, and the nameplate 3 is used for Identify the position information of the high-performance metal reflective type insulation block 1.

[0057] The connecting joint connecting the seam is a non-detachable connection, and the non-detachable connection adopts a fixed joint 12 to connect, and the fixed joint 12 is a blind rivet joint.

[0058] Further, the handle 2 can be held by hand, and can be automatically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com