Motion planning model for automobile welding robot

A welding robot, robot movement technology, applied in the direction of manipulators, program control manipulators, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

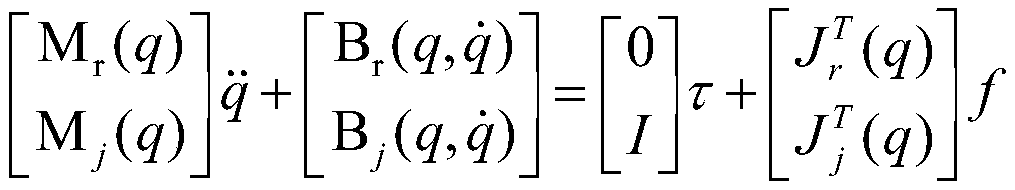

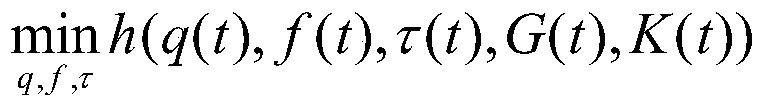

[0039] In the motion planning model of the present invention, the automobile welding robot is defined as a tree-shaped automobile welding robot assembled by joints with some rigid bodies, that is, the main body is a node and the joint is an edge; the motion planning model includes a displacement control variable q (t), which is called configuration, the parameter vector of the joint is the control variable of the motion planning model, q(t) is abbreviated as q, and the admissible function q needs to satisfy the following physical meaning of the motion equation EoM :

[0040]

[0041] = where the subscript r represents the automobile welding robot, the subscript j represents the joint, and M r Indicates the inertia of the automobile welding robot, B r Indicates the influence factor brought by the gravity and speed of the automobile welding robot, M j Indicates the inertia of the joint, B j Indicates the influence factor brought by the gravity and speed of the joint, τ is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com