Spin dryer

A technology of a drying machine and a drying barrel, which is applied in the field of drying machines, can solve the problems such as the inability of the brushes 17 to be gathered into a docile one, the small size of the nail polish brush 13, the difficulty of precise clamping, etc., so as to save investment costs and labor. The effect of cost, small footprint and high plant utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

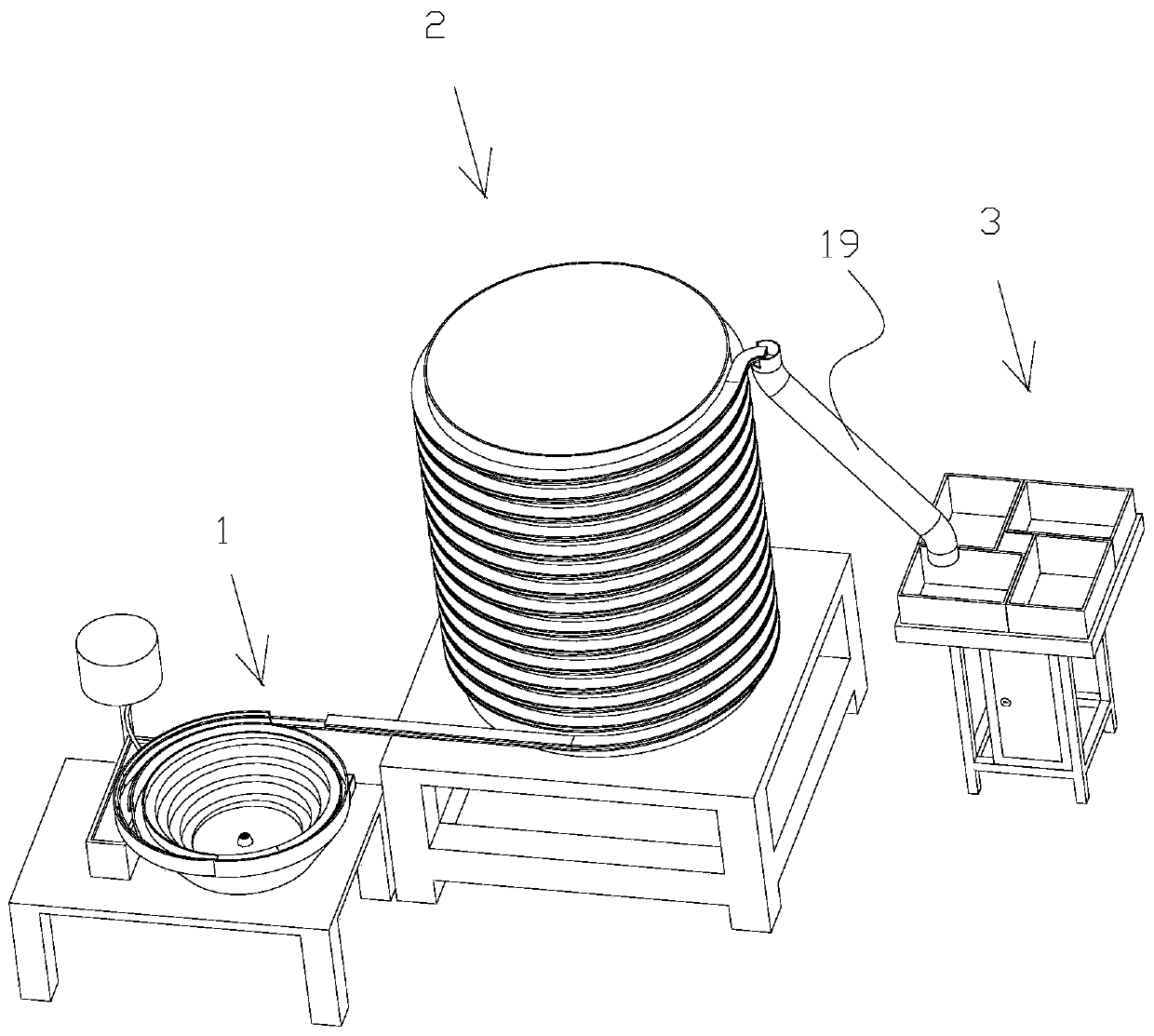

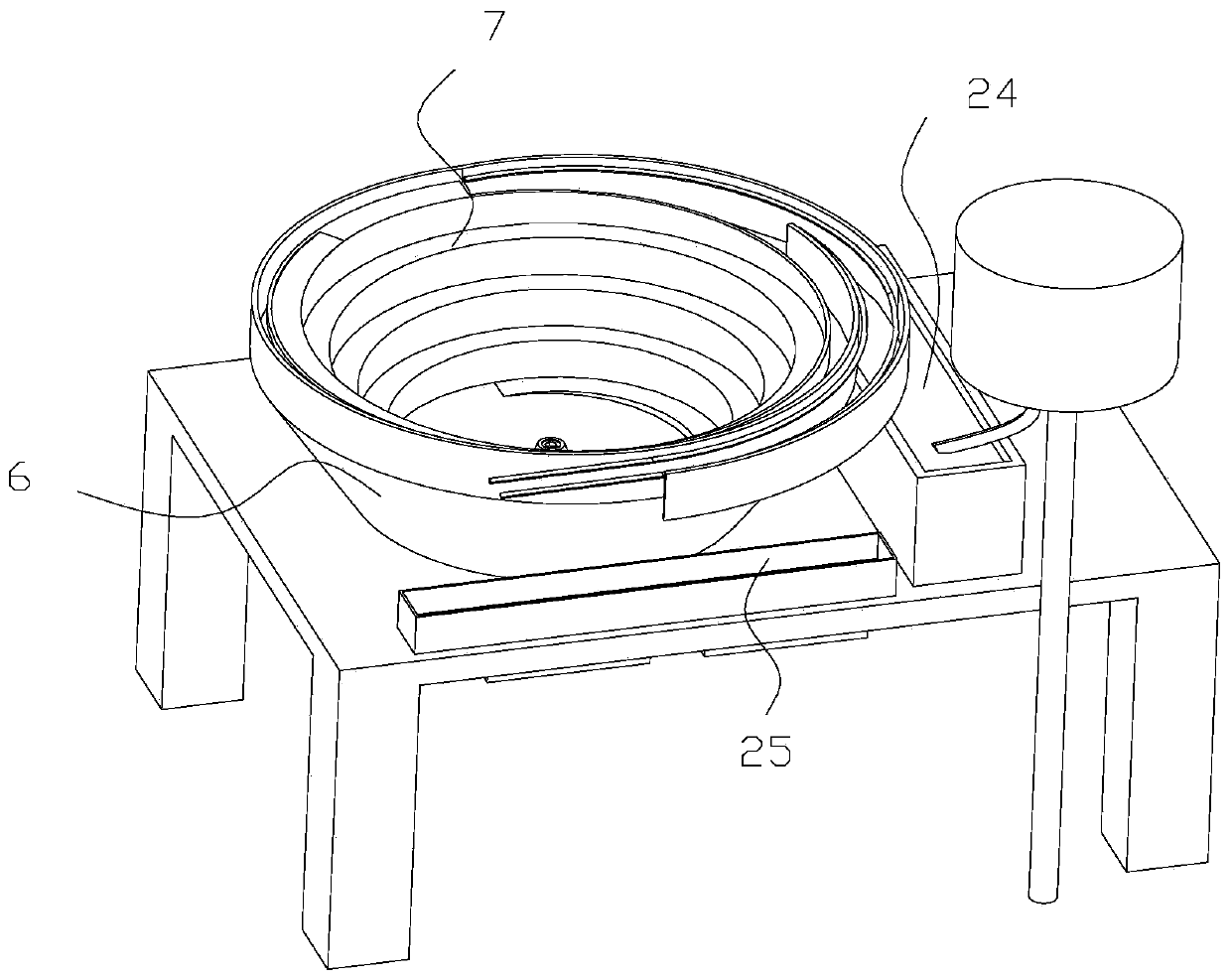

[0031] As shown in the figure, a drying machine includes a feeding device 1, a drying device 2 and an unloading device 3 connected in sequence, and the drying device 2 includes a frame and a drying barrel 8 and a vibration Device 9, the outer wall of spin-drying bucket 8 is provided with the feeding track 10 of spiral rise, and the lower end of feeding track 10 is provided with the feeding opening 11 that is used to dock the feeding device 1, and the upper end of feeding track 10 is provided with for docking. The feeding port 12 of the feeding device 3, the middle part of the feeding track 10 is provided with a transport channel 18 along the length direction, the nail polish brush holder 14 is mounted on the feeding track 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com