Method for preparing polyethersulfone hollow fiber gas separation membrane

A technology of gas separation membrane and polyethersulfone, which is applied in the field of membrane separation, can solve the problems of limited application range and high selectivity of hollow fiber membranes, and achieve the effects of high gas selective separation performance, easy operation, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

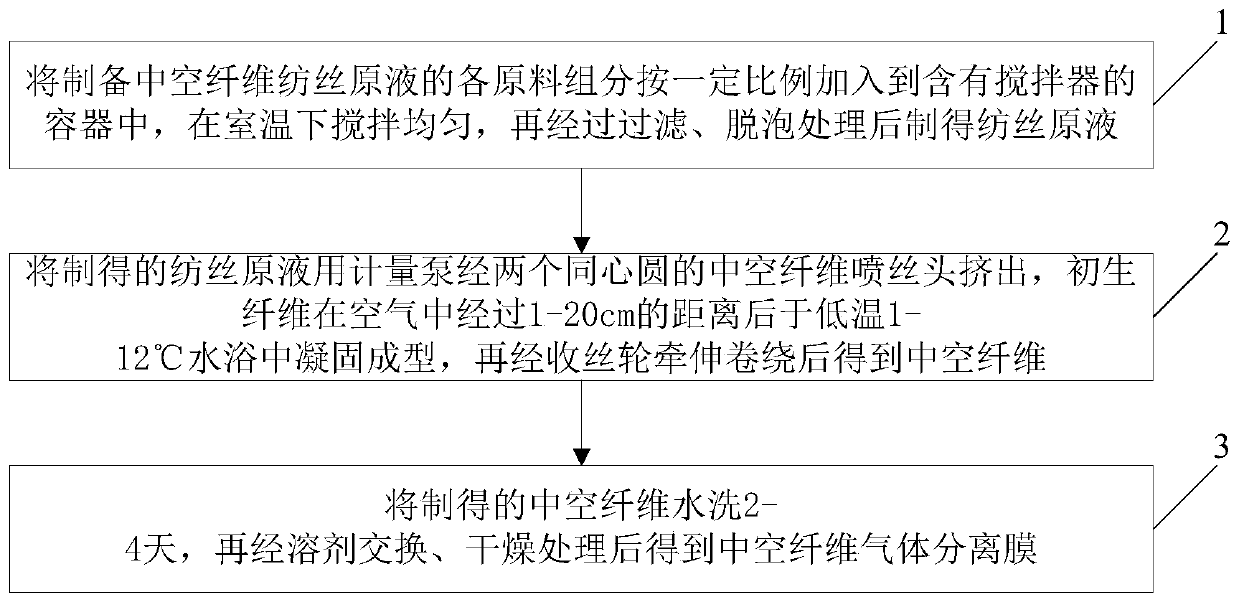

Method used

Image

Examples

Embodiment 1

[0033] Example 1. Add 28 grams of polyethersulfone, 57 grams of N-methylpyrrolidone, and 15 g of diethylene glycol into a container with a stirrer, stir at room temperature to make it fully dissolve, and filter and defoam to form a spinning stock solution .

[0034] Two concentric hollow fiber spinnerets are used to filter the raw spinning fluid and extrude through the spinnerets with a metering pump; the extrusion speed of the spinning solution is 3ml / min; the as-spun fibers pass through a distance of 3cm in the air Solidified and formed in a water bath at a temperature of 7°C; the winding speed of the winding wheel was 8m / min to obtain a polyethersulfone hollow fiber gas separation membrane.

[0035] The outer diameter of the fiber is 570 μm and the inner diameter is 280 μm. The membrane module made of post-treated polyethersulfone hollow fiber has a selectivity of 7 for oxygen and nitrogen, 47 for carbon dioxide and nitrogen, and 40 for carbon dioxide and methane.

Embodiment 2

[0036] Example 2. Add 28 grams of polyethersulfone, 55 grams of N-methylpyrrolidone, and 17 g of diethylene glycol into a container with a stirrer, stir at room temperature to make it fully dissolve, and filter and defoam to form a spinning stock solution .

[0037] Two concentric hollow fiber spinnerets are used to filter the raw spinning fluid and extrude through the spinnerets with a metering pump; the extrusion speed of the spinning solution is 3ml / min; the as-spun fibers pass through a distance of 3cm in the air Solidified and formed in a water bath at a temperature of 6°C; the winding speed of the winding wheel was 8m / min to obtain a polyethersulfone hollow fiber gas separation membrane.

[0038] The outer diameter of the fiber is 670 μm and the inner diameter is 300 μm. The membrane module made of post-treated polyethersulfone hollow fiber has a selectivity of 5 for oxygen and nitrogen, 40 for carbon dioxide and nitrogen, and 30 for carbon dioxide and methane.

Embodiment 3

[0039] Example 3: Add 30 grams of polyethersulfone, 55 grams of N-methylpyrrolidone, and 15 grams of diethylene glycol into a container with a stirrer, stir at room temperature to fully dissolve, and filter and defoam into a spinning stock solution .

[0040] Two concentric hollow fiber spinnerets are used to filter the raw spinning fluid and extrude through the spinnerets with a metering pump; the extrusion speed of the spinning solution is 3ml / min; the as-spun fibers pass through a distance of 3cm in the air, Solidified and formed in a water bath at a temperature of 6°C; the winding speed of the winding wheel was 8m / min to obtain a polyethersulfone hollow fiber gas separation membrane.

[0041] The outer diameter of the fiber is 660 μm and the inner diameter is 240 μm. The membrane module made of post-treated polyethersulfone hollow fiber has a selectivity of 6 for oxygen and nitrogen, 34 for carbon dioxide and nitrogen, and 22 for carbon dioxide and methane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com