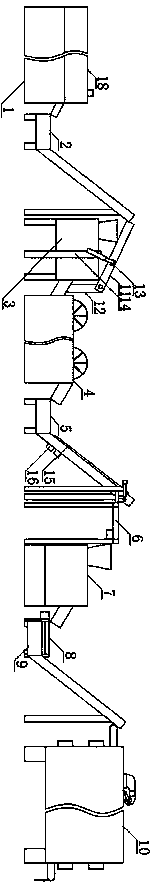

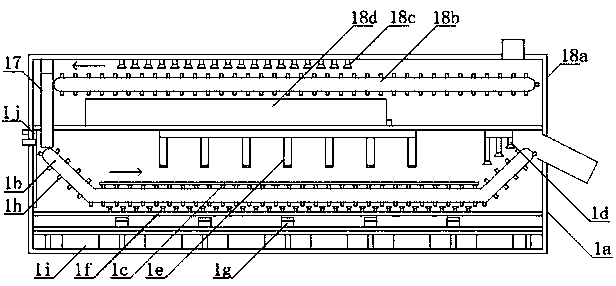

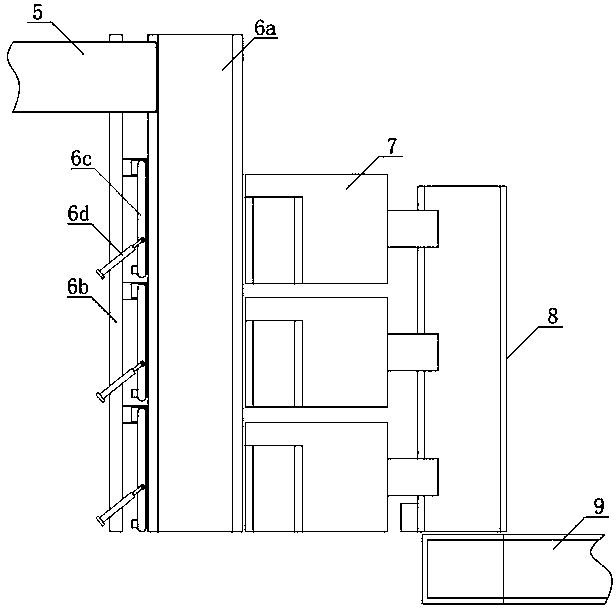

Production system of dehydrated edible fungi and production method of production system

A production system and edible fungus technology, applied in the field of dehydrated edible fungus production system, can solve the problems of uninterrupted processing, low degree of automation, troubles, etc., to improve the effect of centrifugal dehydration, large processing capacity, and improve cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The production method of the production system for dehydrating edible fungi is to clean the edible fungi first, then put the edible fungi into the sodium hypochlorite solution for disinfection and rinsing, the disinfection and rinsing time is 0.5min, blow the sterilized edible fungi for pre-dehydration treatment, and then carry out centrifugal dehydration , and then dry the edible mushrooms with hot air, the temperature of hot air drying is 70°C, and the drying time is 10 minutes.

Embodiment 2

[0057] The production method of the production system for dehydrating edible fungi is to first clean the edible fungi, then put the edible fungi into the sodium hypochlorite solution for disinfection and rinsing, the disinfection and rinsing time is 2 minutes, blow the sterilized edible fungi for pre-dehydration treatment, and then carry out centrifugal dehydration, Then dry the edible fungus with hot air, the temperature of hot air drying is 90°C, and the drying time is 60 minutes.

Embodiment 3

[0059] The production method of the production system for dehydrating edible fungi is to clean the edible fungi first, then put the edible fungi into the sodium hypochlorite solution for disinfection and rinsing, the disinfection and rinsing time is 1.3min, blow the sterilized edible fungi for pre-dehydration treatment, and then carry out centrifugal dehydration , and then dry the edible fungus with hot air, the temperature of hot air drying is 80°C, and the drying time is 35min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com