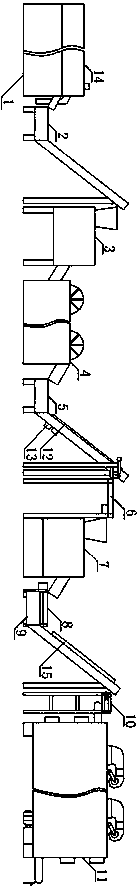

Production system for dewatered chives and production method of system

A production system, technology of dehydrating chives, applied in the direction of preservation of fruits/vegetables through dehydration, application, food processing, etc., can solve the problems of low degree of automation, poor quality, need to wait, etc., to achieve improved cleaning effect and large processing capacity , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

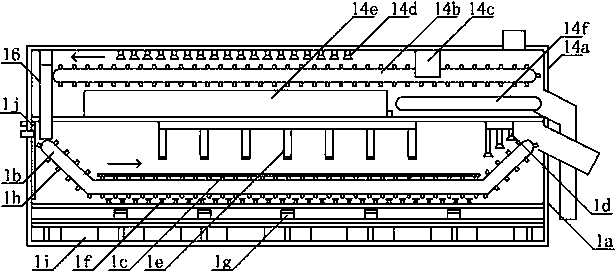

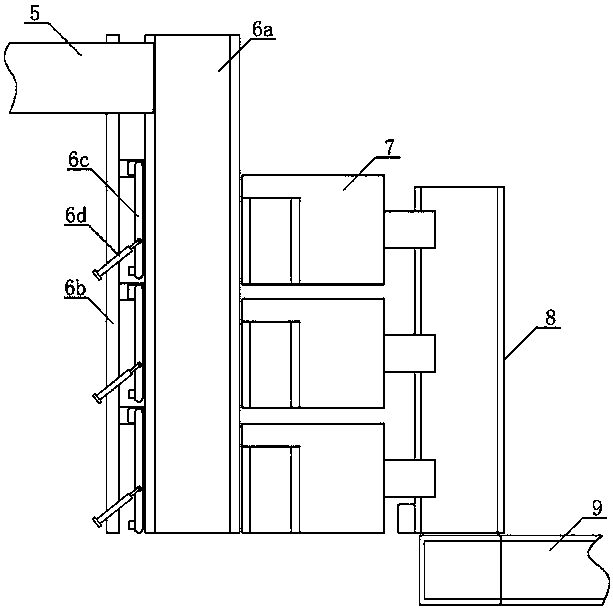

Method used

Image

Examples

Embodiment 1

[0047] Dehydrated shallots use the production method of the production system. First clean the shallots, then cut them into scallions, and then put the scallions into sodium hypochlorite solution for disinfection and rinsing. The disinfection and rinsing time is 0.5min, and the sterilized shallots are pre-dehydrated by blowing air. treatment, then carry out centrifugal dehydration, and then preheat the onion grains after centrifugal dehydration. The preheating temperature is 50°C, and the preheating time is 0.5min. The temperature is 70°C, and the drying time is 10 minutes.

Embodiment 2

[0049] Dehydrated shallots use the production method of the production system. First clean the shallots, then cut them into scallions, and then put the scallions into sodium hypochlorite solution for disinfection and rinsing. The disinfection and rinsing time is 2 minutes, and the sterilized shallots are blown for pre-dehydration. , and then carry out centrifugal dehydration, and then preheat the onion grains after centrifugal dehydration. The preheating temperature is 60°C, and the preheating time is 2min. The temperature is 90°C, and the drying time is 30 minutes.

Embodiment 3

[0051]Dehydrated shallots use the production method of the production system. First clean the shallots, then cut them into scallions, and then put the scallions into sodium hypochlorite solution for disinfection and rinsing. The disinfection and rinsing time is 1.3 minutes, and the sterilized shallots are pre-dehydrated by blowing air. treatment, then carry out centrifugal dehydration, and then preheat the onion grains after centrifugal dehydration. The preheating temperature is 55°C, and the preheating time is 1.3min. The temperature is 80°C, and the drying time is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com