Cultivation method for decreasing tobacco incidence rate and improving tobacco quality

A cultivation method and morbidity technology, applied in the fields of tobacco cultivation, land preparation, preparation of organic fertilizers, etc., can solve the problems of low quality and high morbidity, and achieve the effects of high organic matter content, improvement of soil structure, and improvement of soil compaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

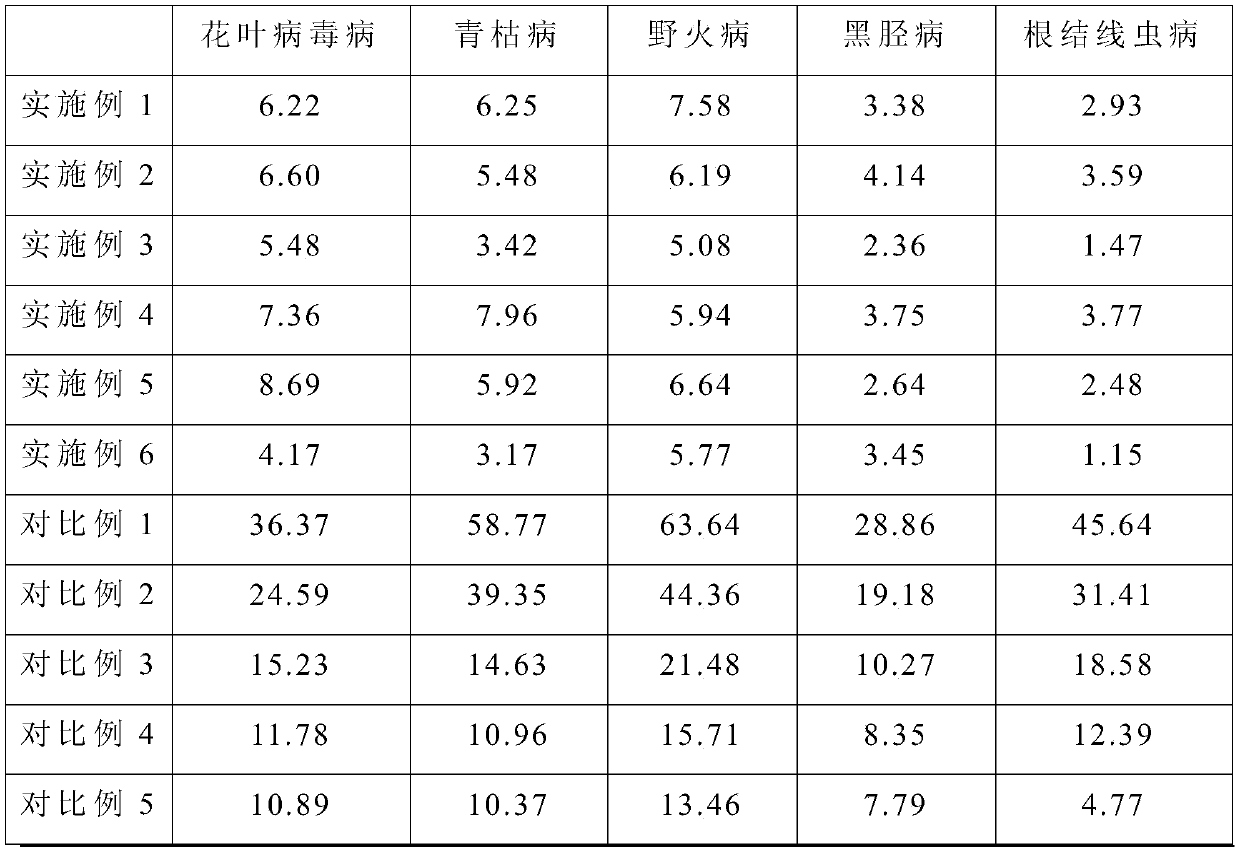

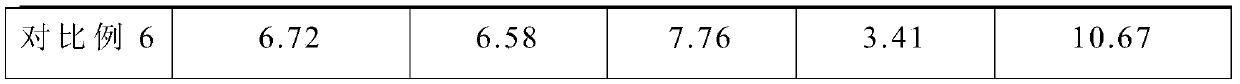

Examples

Embodiment 1

[0026] A cultivation method for reducing tobacco incidence and improving tobacco quality, comprising the following steps:

[0027] (1) Tobacco field finishing: clean up the tobacco stumps, carry out deep plowing and loosening of the soil with a powder ridge machine, and remove the soil from the soil surface to the soil depth of 40 cm;

[0028] (2) Prepare and apply organic materials: the organic materials include the following components in parts by weight: 40 parts of tobacco stalks, 40 parts of waste tobacco leaves, 10 parts of biochar, 30 parts of vermicompost, 10 parts of decomposed cow dung, onion 20 parts of skin, 10 parts of mustard leaves, 15 parts of leek residue, 5 parts of biogas residue and 20 parts of potassium humate, respectively apply the above-mentioned organic materials in three soil layers of 40cm, 20cm and soil surface. The ratio of organic material application rate is 1:1:1, and the total application rate of organic material is 750kg / mu. After the lower tw...

Embodiment 2

[0034] A cultivation method for reducing tobacco incidence and improving tobacco quality, comprising the following steps:

[0035] (1) Tobacco field finishing: clean up the tobacco stumps, carry out deep plowing and loose plowing of the soil with a powder ridge machine, and remove the soil from the soil surface to the soil depth of 50 cm;

[0036] (2) Prepare and apply organic materials: the organic materials include the following components in parts by weight: 60 parts of tobacco stalks, 30 parts of waste tobacco leaves, 20 parts of biochar, 20 parts of vermicompost, 15 parts of decomposed cow dung, onion 15 parts of bark, 15 parts of mustard leaves, 10 parts of leek residue, 10 parts of biogas residue and 15 parts of potassium humate. Apply the above-mentioned organic materials in the three soil layers of 50cm, 25cm and soil surface respectively. The application rate of organic materials is 1:2:1, and the total application rate of organic materials is 500kg / mu. After the lower...

Embodiment 3

[0042] A cultivation method for reducing tobacco incidence and improving tobacco quality, comprising the following steps:

[0043] (1) Tobacco field finishing: clean up the tobacco stumps, carry out deep plowing and loosening of the soil with a powder ridge machine, and remove the soil from the soil surface to the soil depth of 60 cm;

[0044] (2) Prepare and apply organic materials: the organic materials include the following components in parts by weight: 80 parts of tobacco stalks, 20 parts of waste tobacco leaves, 30 parts of biochar, 10 parts of vermicompost, 20 parts of decomposed cow dung, onion 10 parts of skin, 20 parts of mustard leaves, 5 parts of leek residue, 15 parts of biogas residue and 10 parts of potassium humate, respectively apply the above-mentioned organic materials in the three soil layers of 60cm, 30cm and soil surface. The ratio of organic material application rate is 1:2:1, and the total application rate of organic material is 1000kg / mu. After the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com