Closed planar three-electrode switch chip based on LTCC process

A switch chip and three-electrode technology, which is applied in the field of closed planar three-electrode switch chips, can solve the problems of high dimensional accuracy and surface finish, unimproved volume, and high manufacturing costs, so as to realize mass production and improve The effect of repeated trigger frequency and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

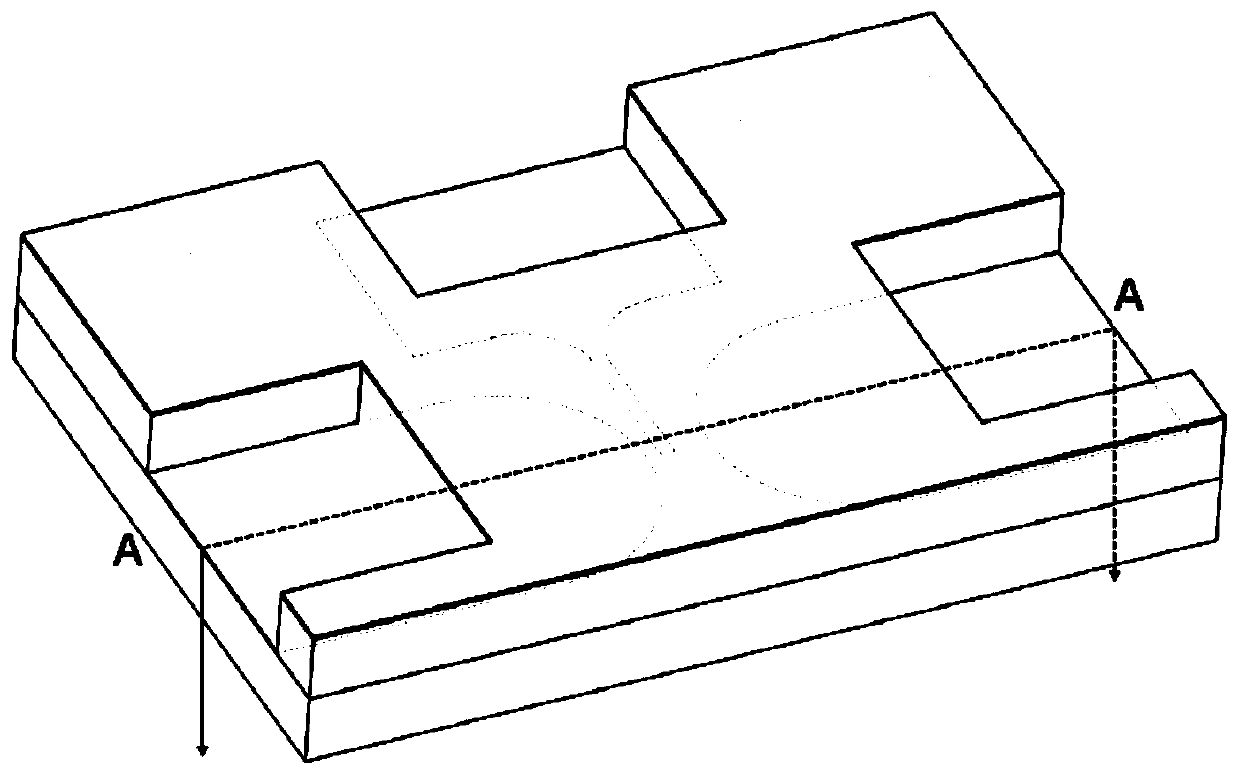

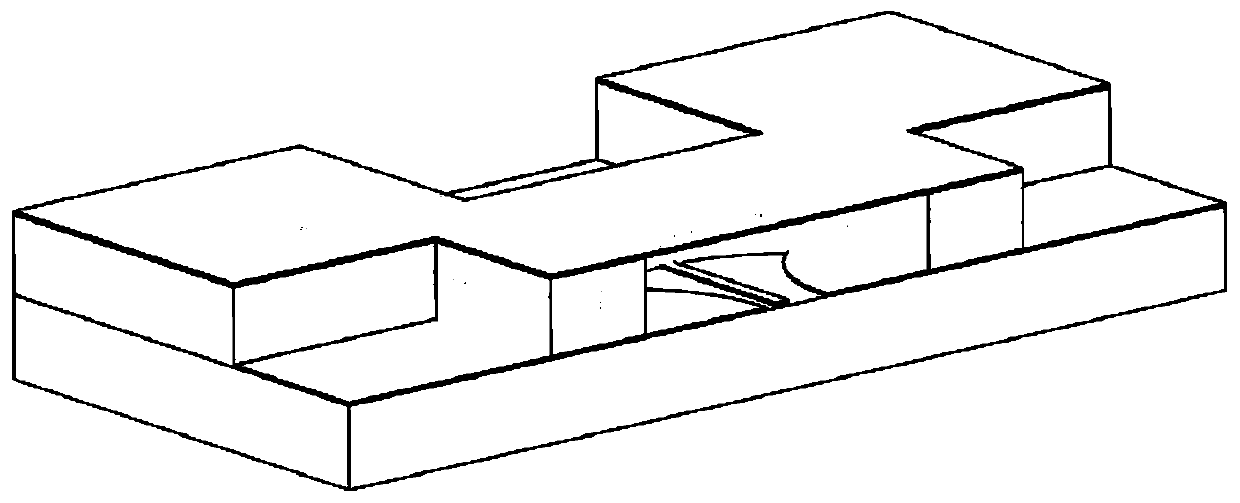

[0053] In this implementation case, a closed planar three-electrode switch chip based on LTCC technology is designed. According to the integrated sintering characteristics of the LTCC process, combined with its processing steps, the switch chip can be divided into four parts: the base layer 1, the metal layer 2, the structure layer A3 and the structure layer B4.

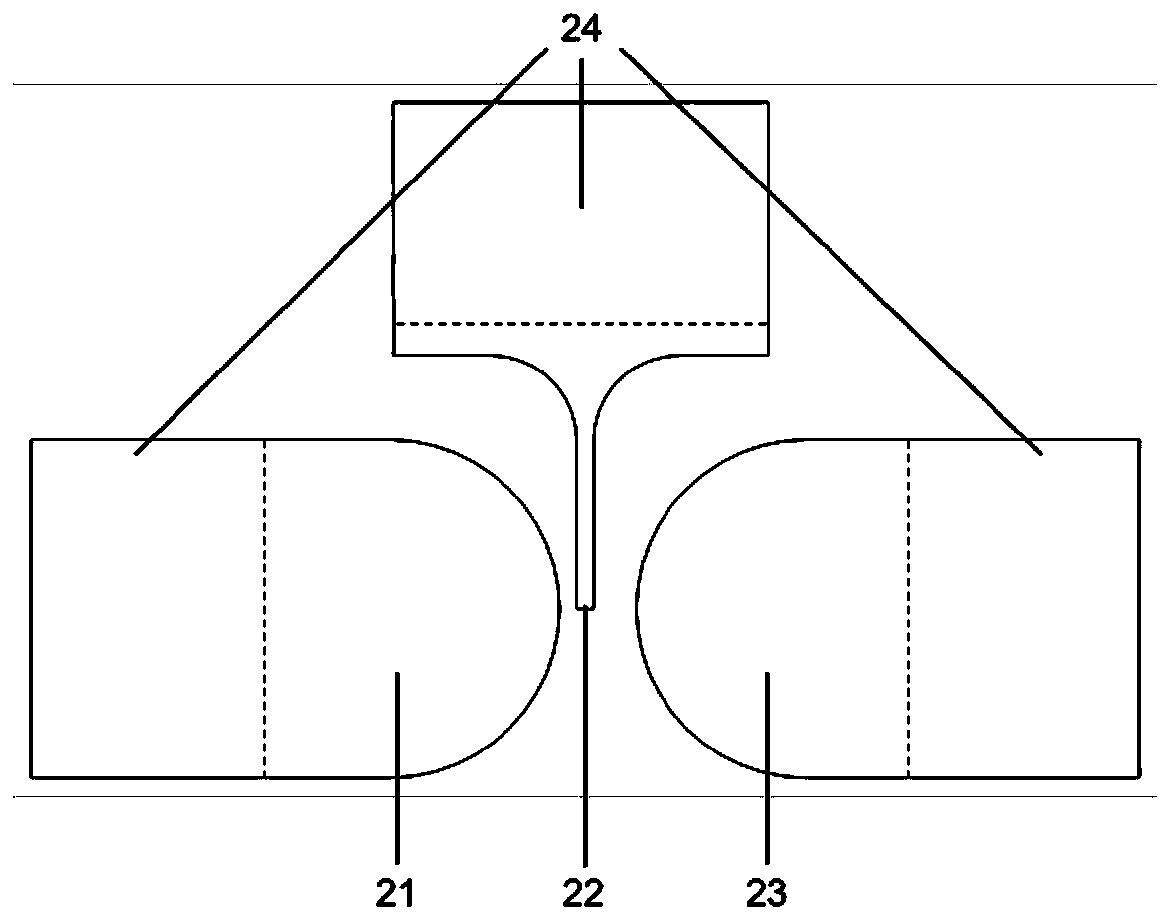

[0054] The base layer 1 is composed of 6-9 layers of green ceramic sheets with a thickness of 110 μm to 114 μm, and serves as a switch carrier in the entire chip. The metal layer 2 adopts the gap screen printing process, uses Au paste as the conductive material, and prints the pattern uniformly on the uppermost green ceramic sheet of the base layer. The thickness of the Au paste is controlled by the thickness of the screen, generally 8 μm to 12 μm; the metal layer 2 may include three electrodes of a planar three-electrode switch, a cathode 21 , a trigger electrode 22 , an anode 23 and a pad 24 for connecting to an ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com