Chinlon hydrophilic softening finishing agent and preparation method thereof

A softening agent and hydrophilic technology, which is applied in the field of nylon hydrophilic softening agent and its preparation, can solve the problems of severe electrostatic phenomenon of nylon fiber materials, poor water absorption of fiber materials, and few hydrophilic groups, etc., and achieve easy-to-obtain raw materials , Overcoming poor water absorption and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

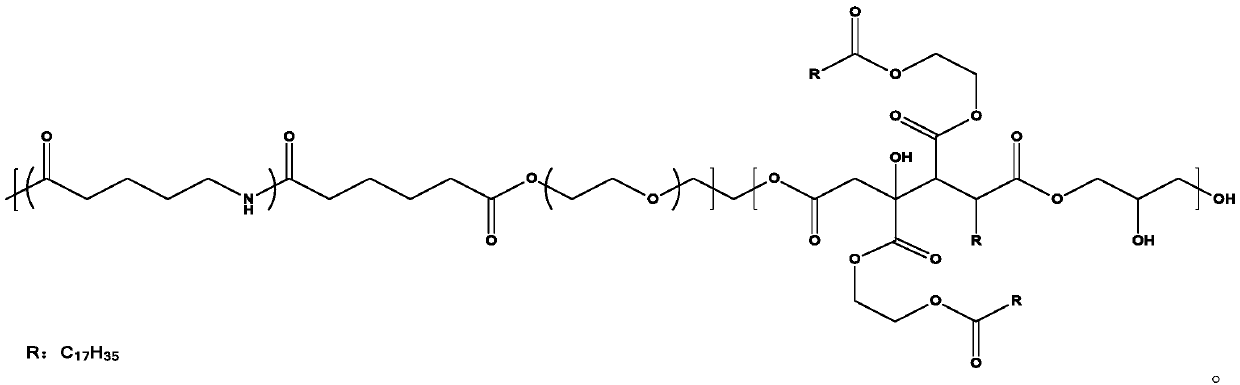

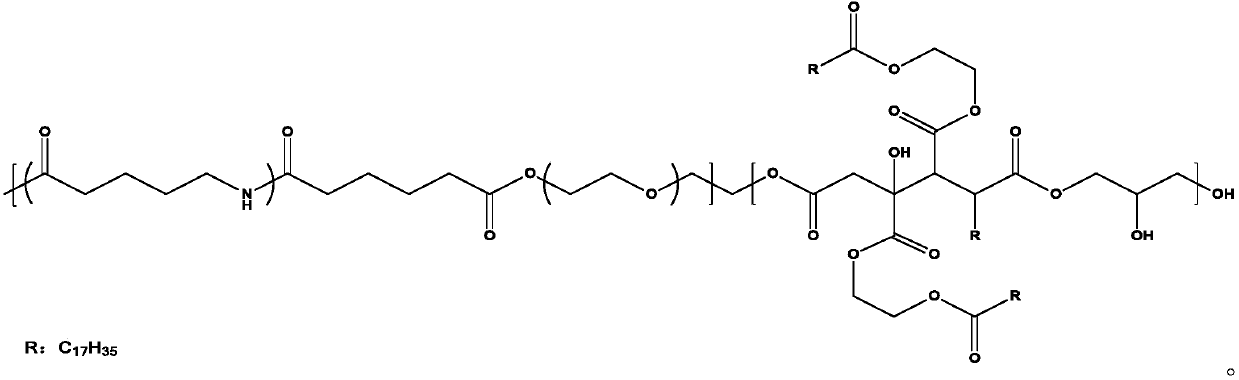

Image

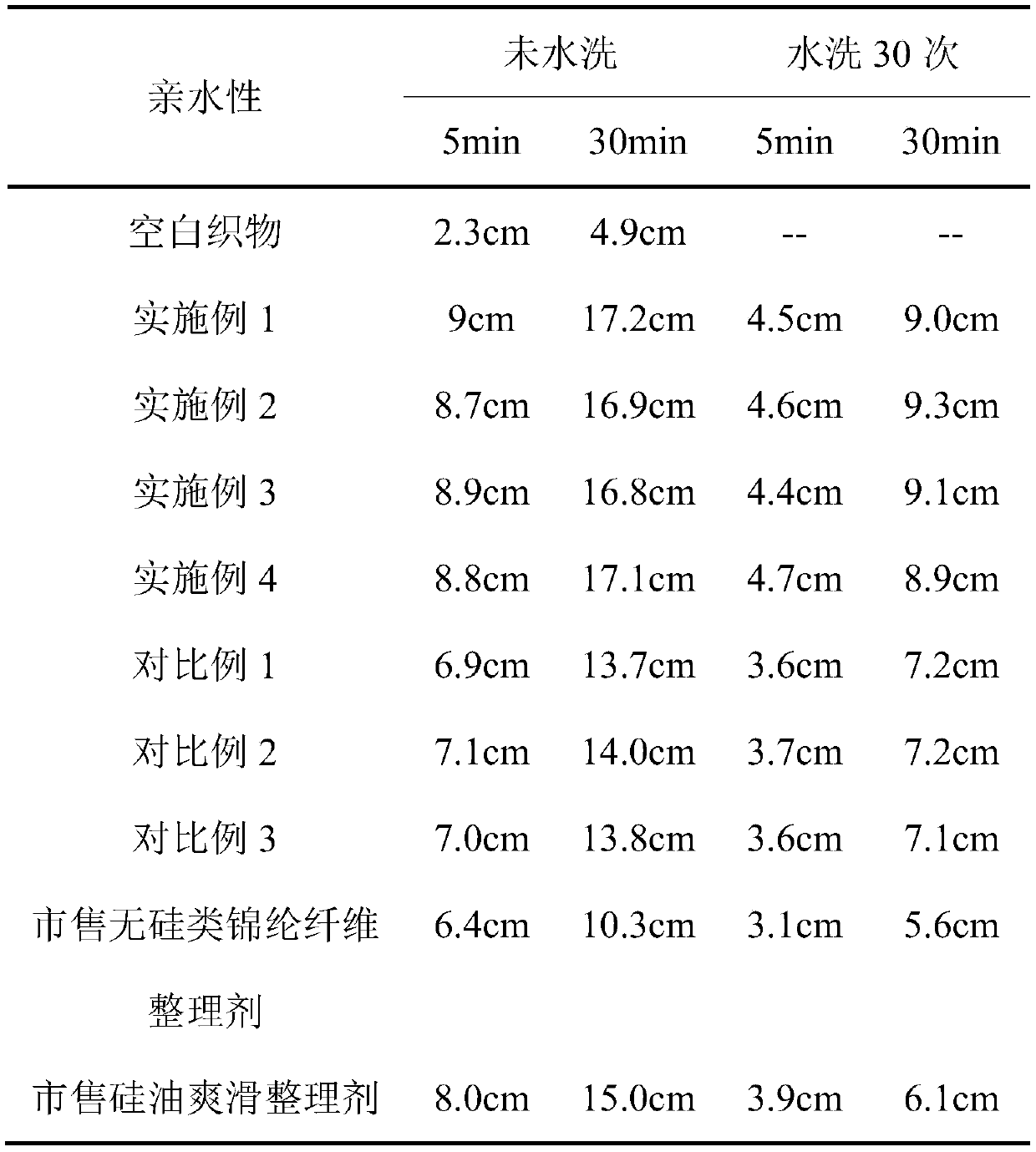

Examples

Embodiment 1

[0016] This embodiment provides a kind of nylon hydrophilic softening finishing agent, and this finishing agent adopts following method to prepare:

[0017] Put 50g polyethylene glycol (molecular weight 1000), 125g glyceryl stearate citrate, 25g adipic acid, 125g ethylene glycol monostearate, 5g caprolactam and 0.41g tert-butyl peroxyneodecanoate In a 250mL four-neck flask equipped with a thermometer, a stirring rod, nitrogen protection and reflux condensation, gradually raise the temperature to 240°C within three hours until no more distillate fractions are distilled, then start to raise the temperature to 250°C and apply vacuum for half an hour to obtain the finishing agent.

Embodiment 2

[0019] This embodiment provides a kind of nylon hydrophilic softening finishing agent, and this finishing agent adopts following method to prepare:

[0020] Put 50g polyethylene glycol (molecular weight 1500), 130g glycerol stearate citrate, 30g adipic acid, 130g ethylene glycol monostearate, 10g caprolactam and 0.66g tetra-n-propyl titanate into the In a 250mL four-necked flask with a thermometer, a stirring rod, nitrogen protection and reflux condensation, gradually raise the temperature to 240°C within three hours until no more distillate fractions are distilled, then start to raise the temperature to 250°C and apply vacuum for half an hour to obtain the finishing agent.

Embodiment 3

[0022] This embodiment provides a kind of nylon hydrophilic softening finishing agent, and this finishing agent adopts following method to prepare:

[0023] 50g polyethylene glycol (molecular weight 2000), 135g glyceryl stearate citrate, 35g adipic acid, 135g ethylene glycol monostearate, 15g caprolactam and 0.92g dimethyl carbonate drop into a thermometer, In a 250mL four-necked flask with a stirring rod, nitrogen protection and reflux condensation, the temperature was gradually raised to 240°C within three hours until no more fractions were distilled, and then the temperature was raised to 250°C and vacuumed for half an hour to obtain the finishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com