Composition for preparing transparent polyurethane, workpiece and forming method thereof, automobile appearance part and forming method

A technology of composition and polyurethane, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, household components, etc., can solve the problems of poor heat resistance, low high temperature hardness, and slow curing speed of parts, and achieve short molding cycle, The effect of fast curing speed and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] (2) Inject the composition for preparing transparent polyurethane of the present invention onto the carbon fiber cloth in the mold through a high-pressure injection machine, and then solidify to obtain an injection part;

[0061] (3) Machining and optional surface treatment are performed on the injection part to obtain a carbon fiber-polyurethane composite part.

[0062] Specifically, including:

[0063] (1) Lay the carbon fiber cloth in the mould, and close the mold to evacuate to a degree of vacuum below 500Pa, preferably below 300Pa;

[0064] (2) The composition for preparing transparent polyurethane of the present invention with a material temperature of 30-60° C. is injected into the carbon fiber cloth in the mold with an injection pressure of 10-20 MPa, preferably 12-15 MPa, through a high-pressure injection machine, and then After curing at a mold temperature of 70-90°C for 2-3 minutes, an injection part is obtained;

[0065] (3) Machining and optional surface ...

Embodiment 1-4 and comparative example 1

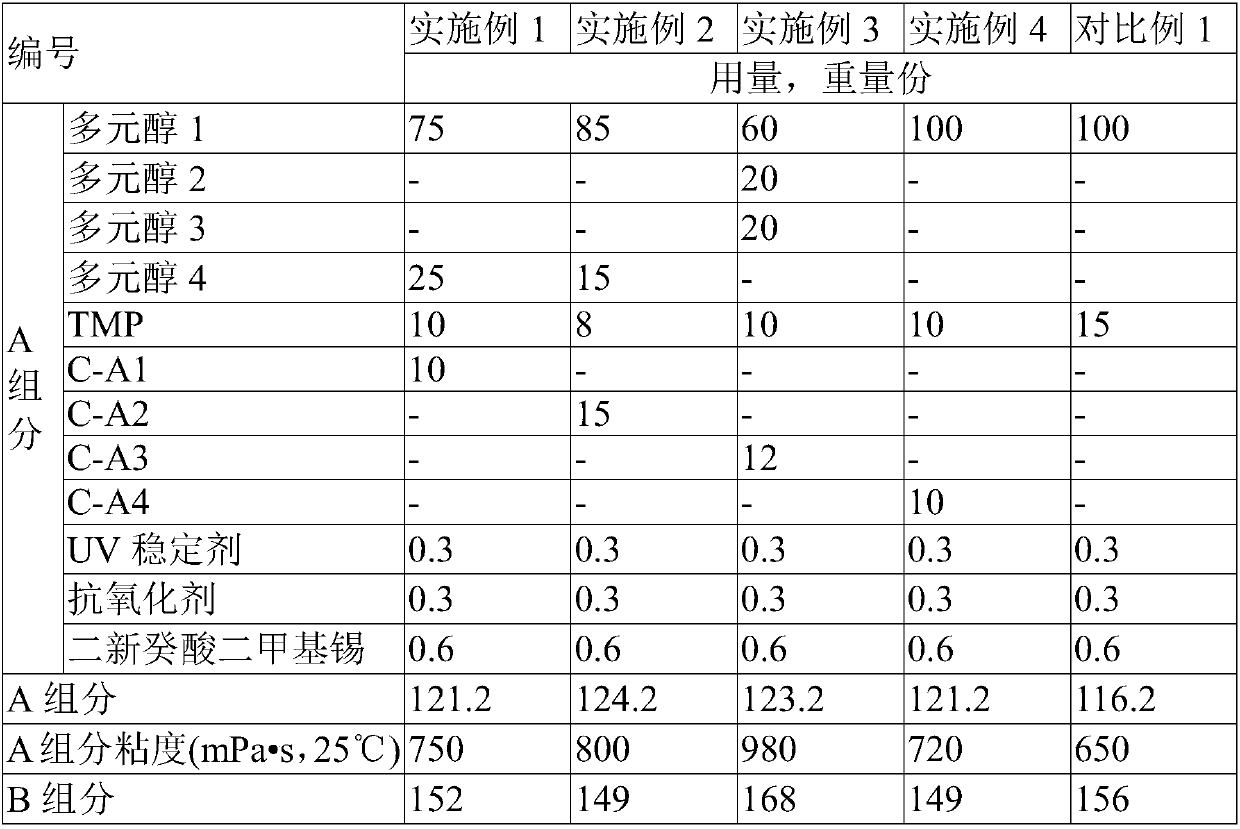

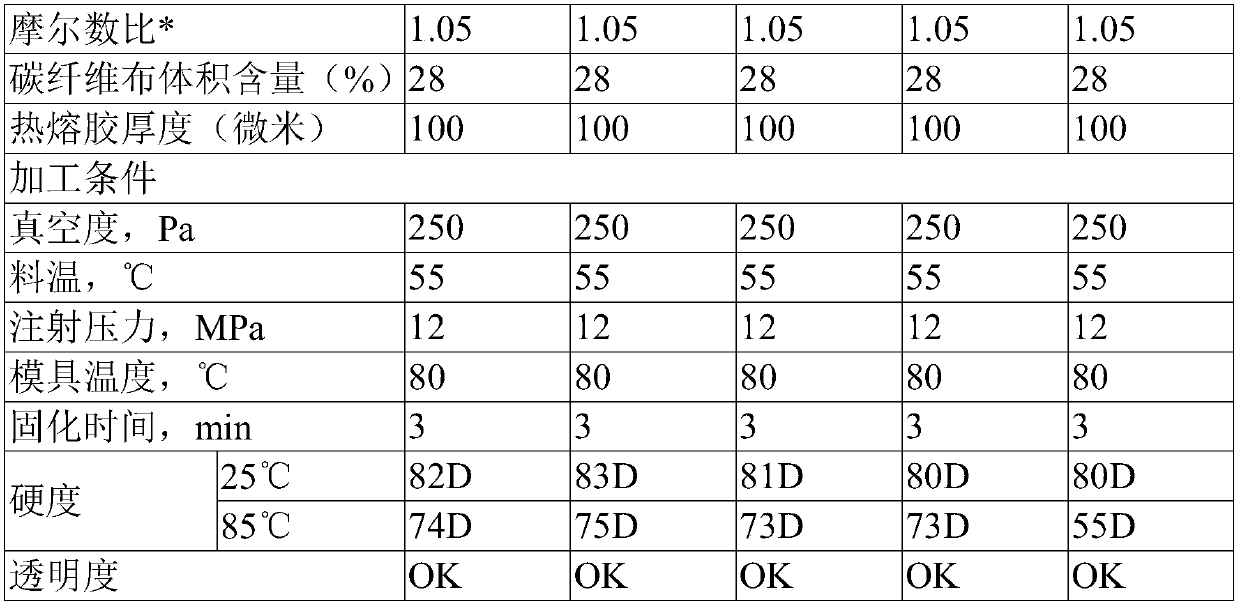

[0103] Prepare A and B components according to the ingredients listed in Table 1.

[0104] Lay the hot-melt adhesive film and 3K carbon fiber cloth in the mold, and close the mold to evacuate; the composition for preparing transparent polyurethane resin composed of component A and component B with material temperature is injected through a high-pressure injection machine. Vacuumized mold, then solidified and molded at a certain mold temperature to obtain injection parts, and then processed to obtain carbon fiber-polyurethane composite parts. The processing conditions and the hardness and transparency of the obtained parts are shown in Table 1.

[0105] Table 1

[0106]

[0107]

[0108] *The molar ratio of the sum of active groups contained in component A to the isocyanate groups contained in component B

[0109] Can find out by the data of above-mentioned embodiment, comparative example and table 1, adopt the technical scheme that the present invention provides can im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com