Multifunctional mineral ceramic hot compress material and preparation method and application thereof

A functional material and multi-functional technology, applied in the field of multi-functional mineral ceramic hot compress material and its preparation, can solve the problems of lack of dehumidification and antibacterial, single function, and relatively expensive price, so as to avoid secondary infection, relieve body pain, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

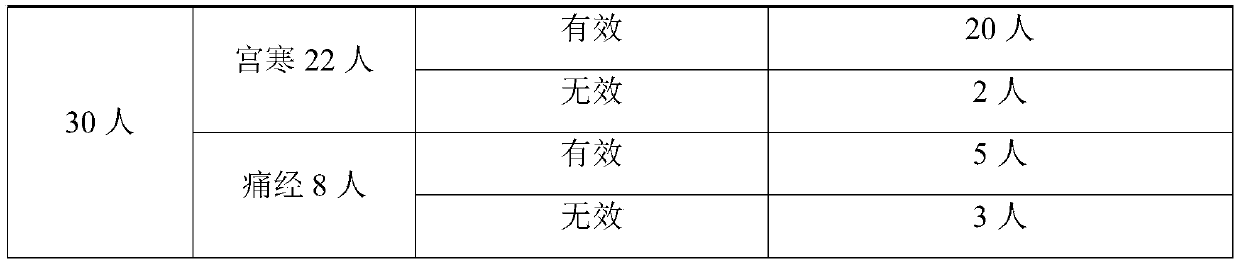

Examples

Embodiment 1

[0044] A multifunctional mineral ceramic hot compress material is made of the following raw materials in weight percentage: 56% of hygroscopic material, 3% of antibacterial material, 30% of functional material, 10% of inorganic binder and 1% of graphene.

[0045] in:

[0046] The hygroscopic material is made of raw materials with the following weight percentages: sepiolite 40%, attapulgite 20%, bentonite 10% and zeolite 30%.

[0047] The antibacterial material is made of the following raw materials in percentage by weight: 95% of nano-zinc oxide, 1% of silver powder and 4% of copper-zinc alloy, and the particle size of nano-zinc oxide is 20-100 nanometers.

[0048] The functional material is made of the following raw materials in weight percentage: 30% of terahertz powder, 50% of meteorite powder, 10% of far-infrared powder and 10% of germanium powder.

[0049] The inorganic binder is a mixture of water glass and sodium metasilicate, and the mass ratio of water glass and sodi...

Embodiment 2

[0055] A multifunctional mineral ceramic hot compress material is made of the following raw materials in weight percentage: 60% of hygroscopic material, 2% of antibacterial material, 28% of functional material, 9% of inorganic binder and 1% of graphene.

[0056] in:

[0057] The hygroscopic material is made of raw materials with the following weight percentages: sepiolite 45%, attapulgite 20%, bentonite 10% and zeolite 25%.

[0058] The antibacterial material is made of the following raw materials in percentage by weight: 94% of nano-zinc oxide, 1% of silver powder and 5% of copper-zinc alloy, and the particle size of nano-zinc oxide is 20-100 nanometers.

[0059] The functional material is made of the following raw materials in weight percentage: 34% of terahertz powder, 46% of meteorite powder, 8% of far-infrared powder and 12% of germanium powder.

[0060] The inorganic binder is a mixture of water glass and sodium metasilicate, and the mass ratio of water glass and sodium...

Embodiment 3

[0066] A multifunctional mineral ceramic hot compress material is made of the following raw materials in weight percentage: 65% of hygroscopic material, 1% of antibacterial material, 25% of functional material, 8% of inorganic binder and 1% of graphene.

[0067] in:

[0068] The hygroscopic material is made of raw materials with the following weight percentages: sepiolite 35%, attapulgite 25%, bentonite 8% and zeolite 32%.

[0069] The antibacterial material is made of the following raw materials in percentage by weight: 96% of nano-zinc oxide, 1% of silver powder and 3% of copper-zinc alloy, and the particle size of nano-zinc oxide is 20-100 nanometers.

[0070] The functional material is made of the following raw materials in weight percentage: 25% of terahertz powder, 55% of meteorite powder, 12% of far-infrared powder and 8% of germanium powder.

[0071] The inorganic binder is a mixture of water glass and sodium metasilicate, and the mass ratio of water glass and sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com