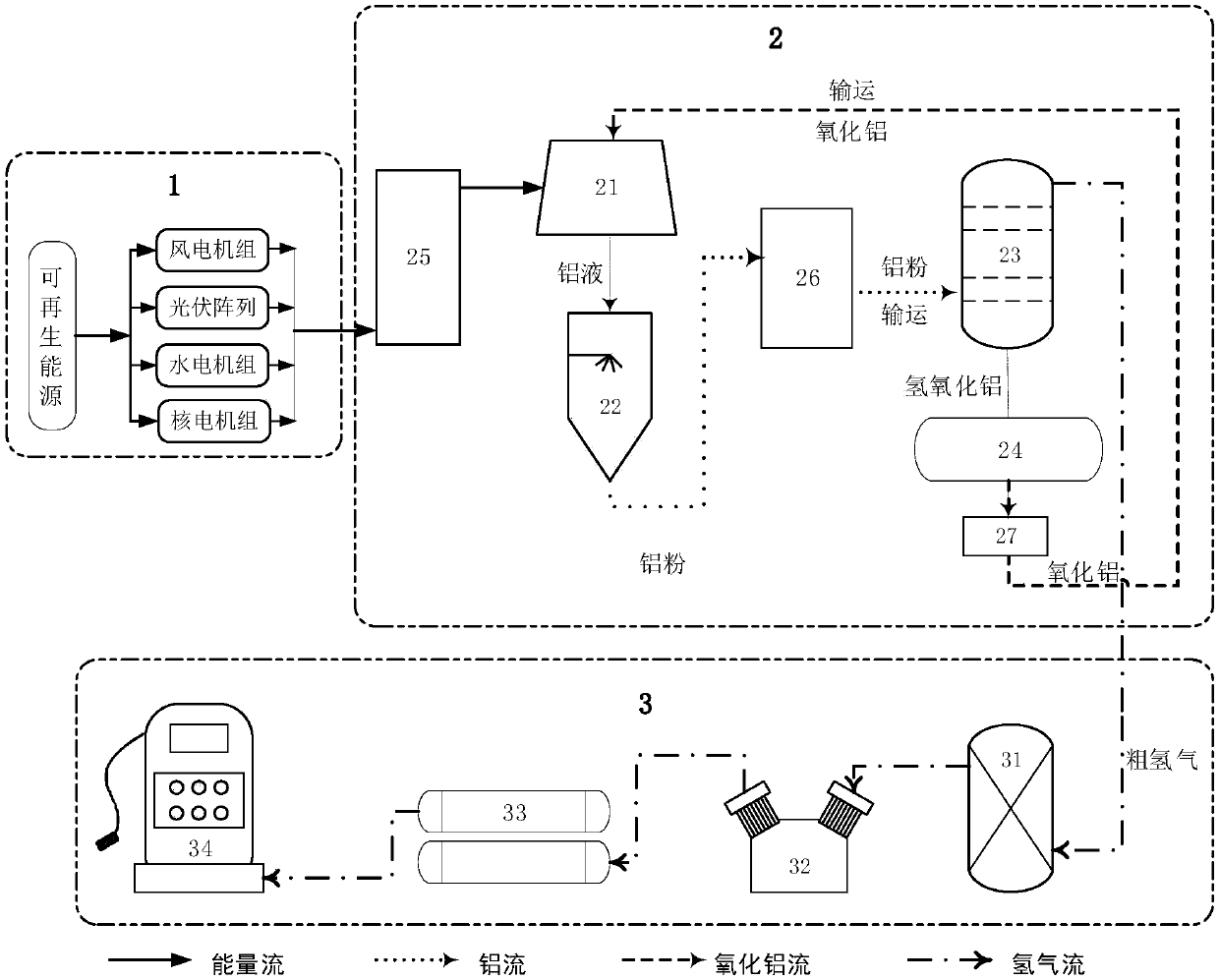

Circulating renewable energy source hydrolysis hydrogen production system and method based on aluminum energy storage

A renewable energy, hydrolysis hydrogen production technology, applied in the direction of hydrogen production, energy input, etc., can solve the problems of serious energy consumption, transportation cost and safety and transportation distance, occupation of fixed asset investment, etc., to reduce Reduce the pressure of peak shaving, enhance transportation safety, and achieve efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

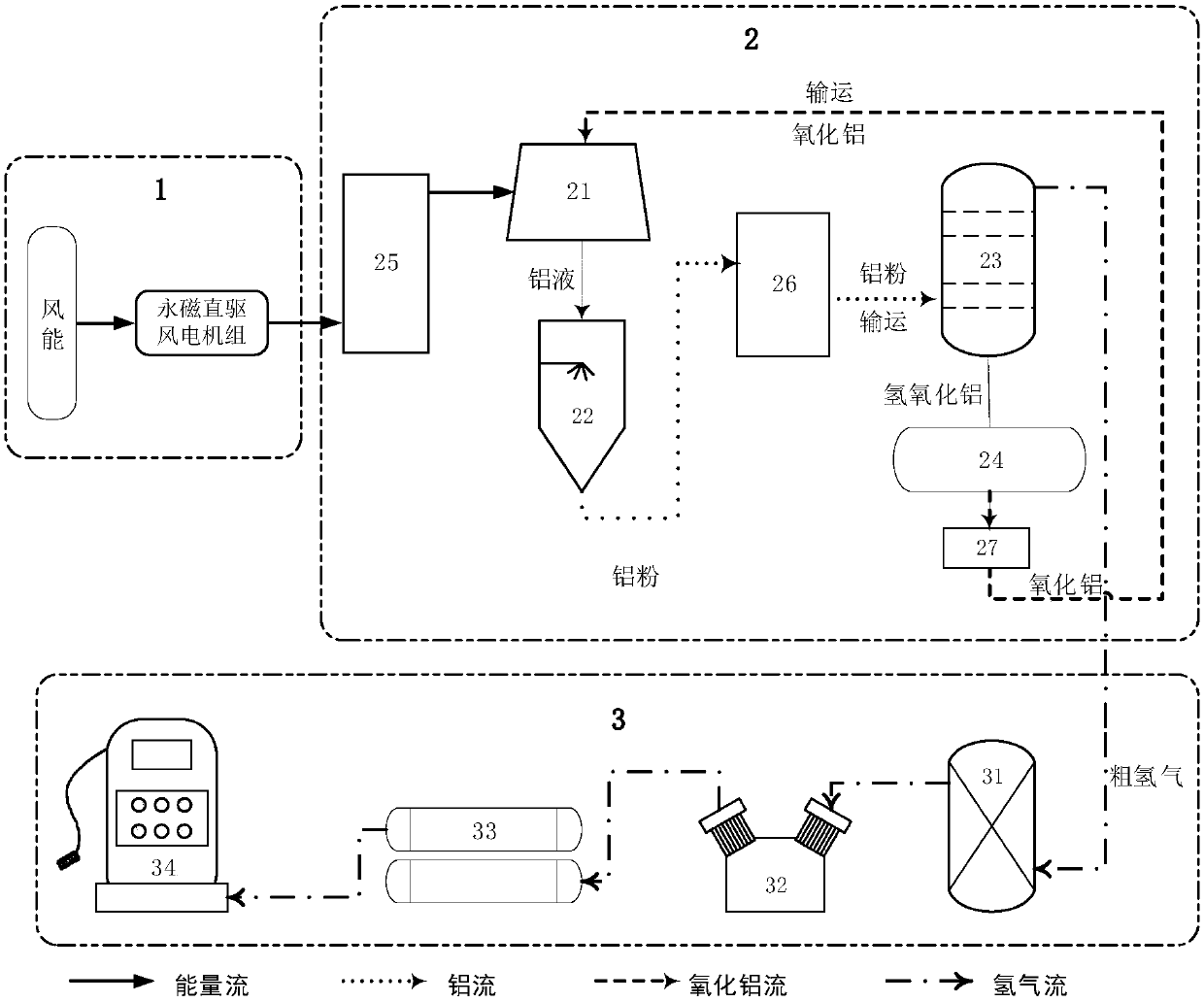

Embodiment 1

[0079] Embodiment 1 of the present invention provides a method for hydrogen production by hydrolysis of circulating wind power based on aluminum energy storage, such as figure 2 As shown, in a certain place in Northeast China, the wind power generated by the wind field equipped with permanent magnet direct drive wind turbines is used as the power supply, and aluminum oxide is added to the aluminum electrolytic tank 21 to be electrolyzed into aluminum liquid, and then directly sent to the nitrogen mist through the liquid guide tank. Aluminum powder is formed in the chemical device 22 and vacuum-packed; then the aluminum powder is transported to the hydrogenation station and enters the aluminum-water reactor 23 to react with pure water for on-site hydrogen production, and the produced crude hydrogen gas containing water vapor enters the hydrogen drying tower 31 After drying, pure hydrogen with a purity of 99.9% is obtained, and then pressed into a 45MPa long-tube gas cylinder 33...

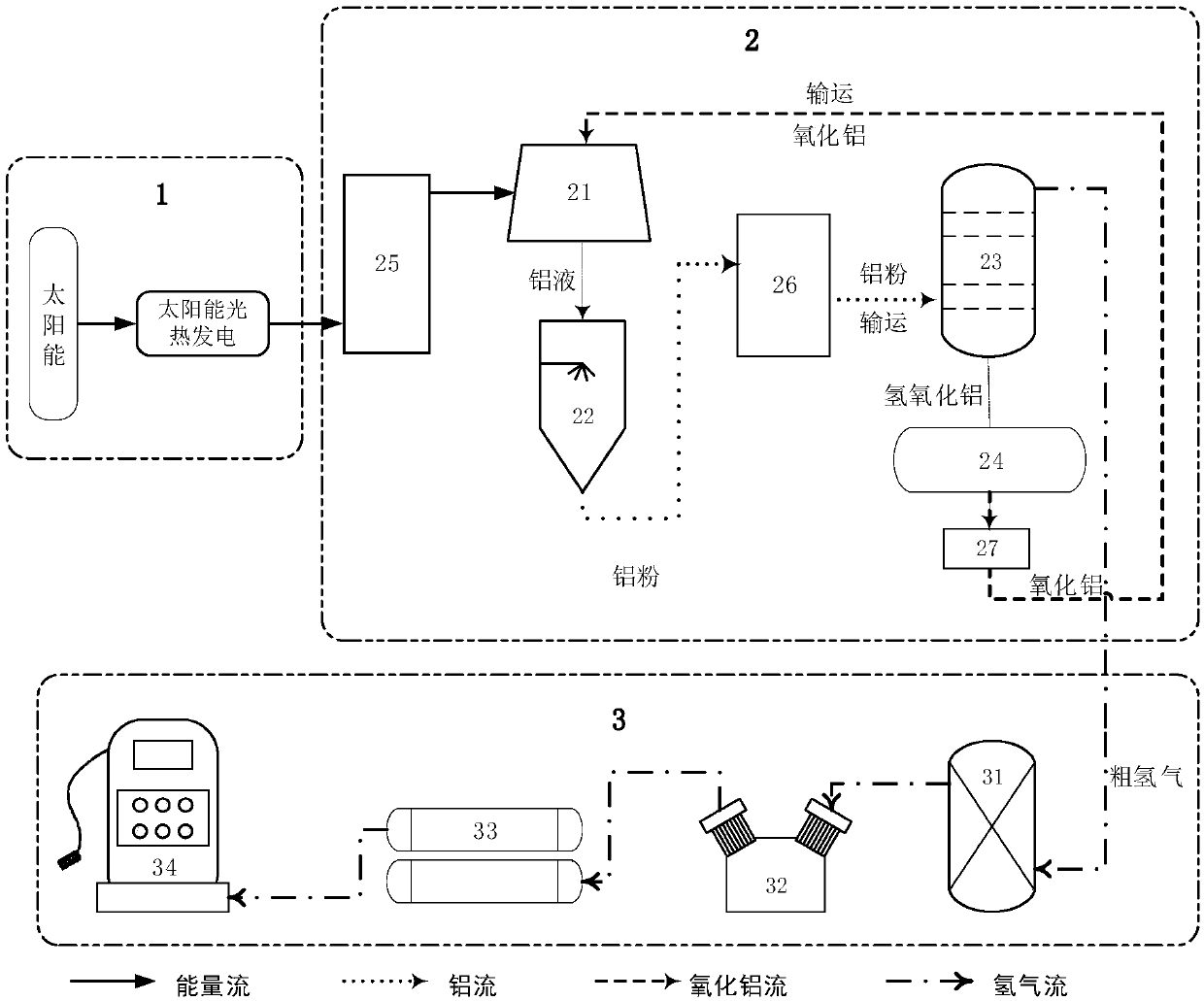

Embodiment 2

[0081] Embodiment 2 of the present invention provides a circulating solar hydrolysis hydrogen production method based on aluminum energy storage, such as image 3 As shown, in a certain place in Xinjiang, the electric energy generated by the electric field equipped with a solar thermal power generation system is used as the power supply, and aluminum oxide is added to the aluminum electrolytic cell 21 to be electrolyzed into aluminum liquid, and then directly sent to the nitrogen mist through the liquid guide tank. Aluminum powder is formed in the chemical device 22 and vacuum-packed; then the aluminum powder is transported to the hydrogenation station and enters the aluminum water reactor 23 to react with an aqueous solution of sodium hydroxide with a mass ratio of 5% to 50% for on-site hydrogen production. Crude hydrogen containing alkali vapor enters the hydrogen drying tower 31 for drying and purification to obtain pure hydrogen with a purity of 99.9%, and then presses it i...

Embodiment 3

[0083] Embodiment 3 of the present invention provides a combined hydrolysis hydrogen production method based on aluminum energy storage of circulating wind energy (double-fed fan) and solar energy (monocrystalline silicon photovoltaic), such as Figure 4 As shown, in Inner Mongolia, the wind power generated by the local doubly-fed asynchronous wind turbine wind farm and the electric energy generated by the monocrystalline silicon photovoltaic panel array are used as combined power supply, and aluminum oxide is added to the aluminum electrolytic cell 21 to be electrolyzed into aluminum After the liquid is directly sent to the nitrogen atomization device 22 through the liquid guide tank to form aluminum powder and vacuum packaged; then the aluminum powder is transported to the hydrogenation station and enters the aluminum-water reactor 23 with a mass ratio of 5% to 50% of hydrogen oxidized Sodium aqueous solution reacts to produce hydrogen on site, and the produced crude hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com