Reciprocating type crusher for recycling treatment of construction waste

A construction waste and recycling technology, which is applied in mechanical equipment, sugarcane machining, wood processing equipment, etc., can solve the problems that restrict the scope of recycling and trouble developers, etc., and achieve the effect of ingenious structure and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

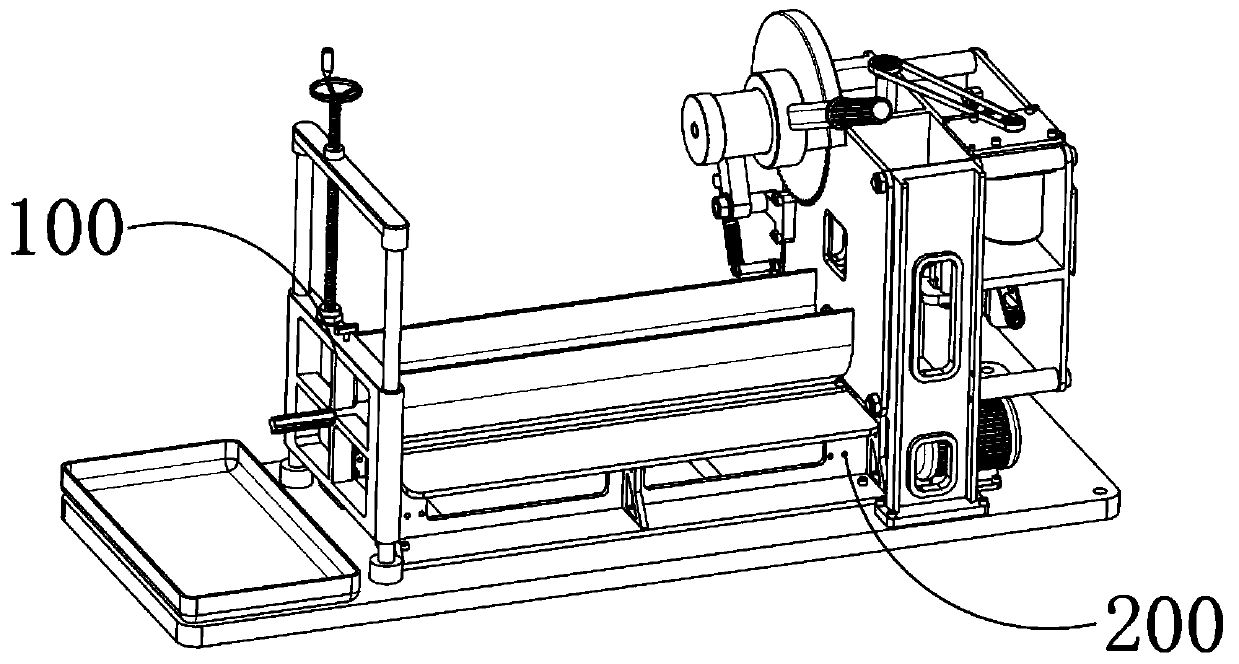

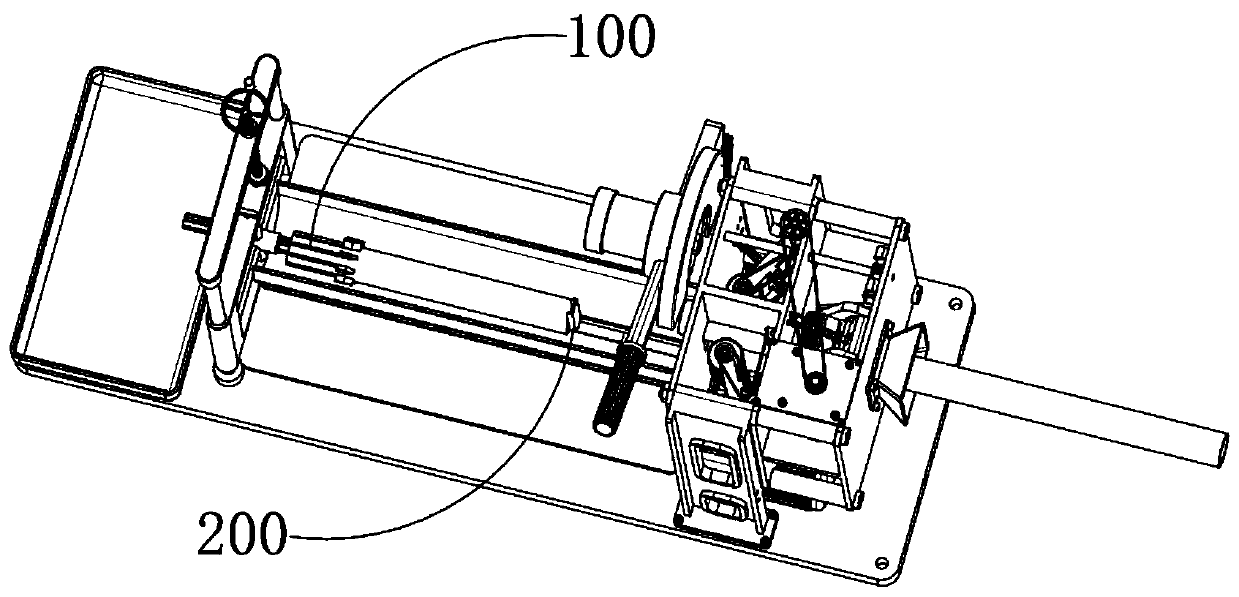

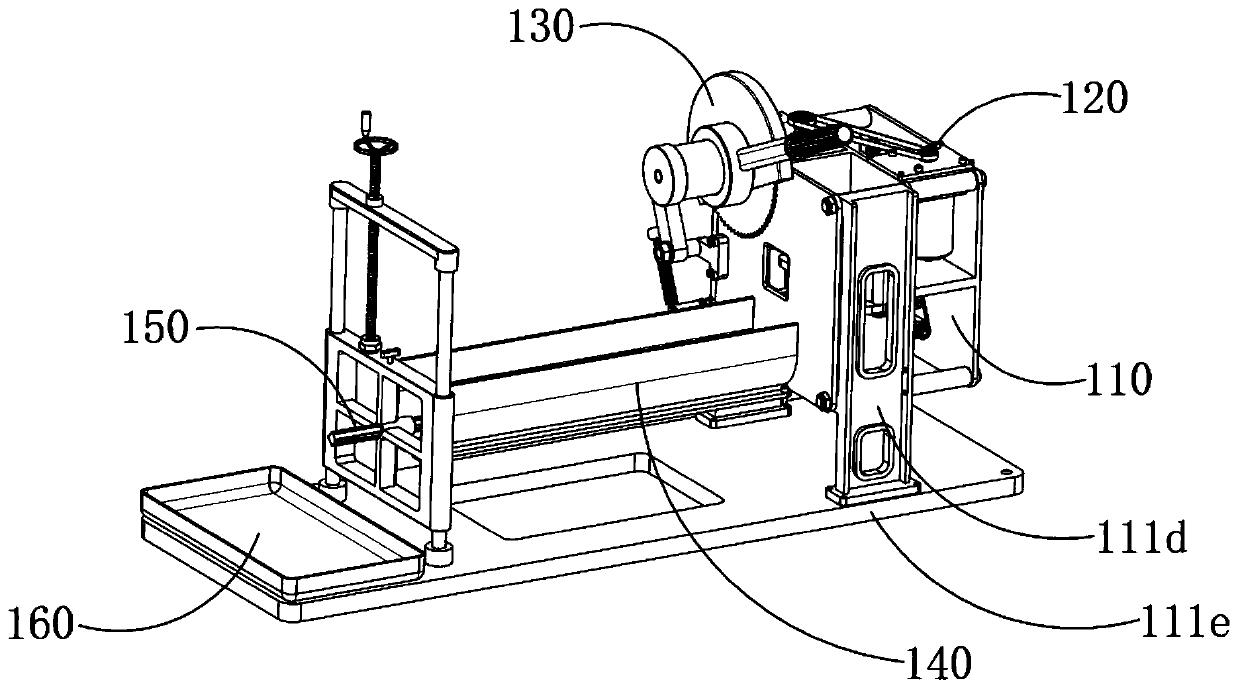

[0065] A reciprocating crusher for recycling construction waste, which includes a crushing device 100 for cutting and crushing wood bars such as bamboo, a traveling drive device 200, and an automatic retraction device 300. The crushing device 100 includes a collection cabin 140, a set The feeding mechanism 110 at one end of the collection cabin 140, the lifting and crushing cutter 150 arranged at the other end of the storage cabin 140, and the cutting mechanism 130 arranged at the discharge port of the feeding mechanism 110 and above the collection cabin 140, the feeding mechanism 110 is used to hold bamboo Such as wood bars and sent to the top of the collection cabin 140, the cutting mechanism 130 is used to cut the bamboo and other wood bars sent to the top of the collection cabin 140, and the collection cabin 140 is used to accept the bamboo cut by the cutting mechanism 130 Such as wood bars, the traveling driving device 200 is used to push the cut bamboo and other wood bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com