MoSe 2-CdS/CdSe composite photocatalyst and preparation method thereof

A mose2-cds, composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of fast photo-generated electron-hole recombination rate, easy photocorrosion, etc., and achieve cheap raw materials. , excellent performance, high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0024] Preparation Example 1 (comparative sample)

[0025] Add 4.5g cadmium chloride hydrate, 4.5g thiourea and 60g ethylenediamine solution (mass ratio of cadmium chloride hydrate: thiourea: ethylenediamine: 100:100:1333) into the beaker, and stir for 1 hour with magnetic force. Pour the above mixture into a 100ml corrosion-resistant stainless steel hydrothermal reactor at room temperature, raise the temperature to 160°C, and seal the reaction for 48h. The suspension was centrifuged, the solid was washed with distilled water, and finally dried at 60°C for 12 hours to obtain CdS powder. The CdS prepared by this method has a nanorod structure, and the photocatalytic water splitting hydrogen production activity was evaluated under AM 1.5, and the hydrogen production rate was 0.012 mmol / g / h.

preparation Embodiment 2

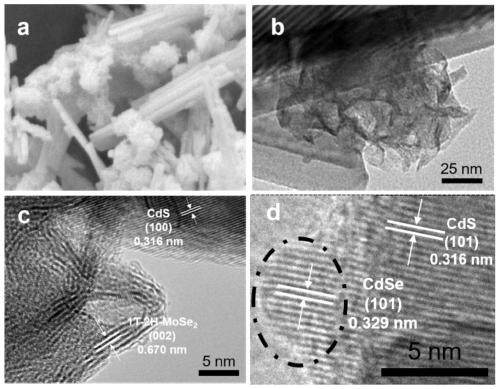

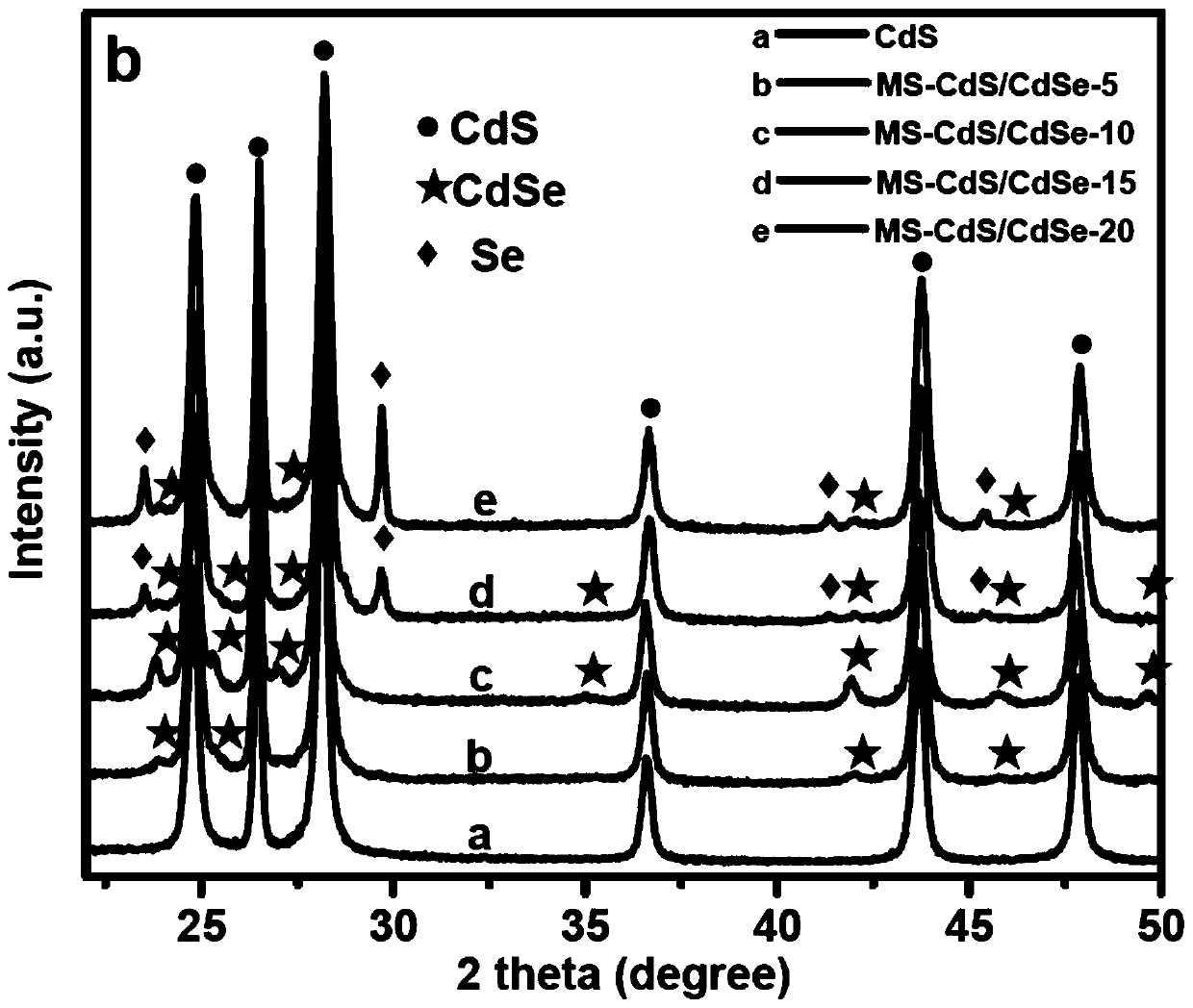

[0027]Add 4.5g of cadmium chloride hydrate, 4.5g of thiourea and 60g of ethylenediamine solution (mass ratio of cadmium chloride hydrate: thiourea: ethylenediamine: 100:100:1333) into the beaker, and magnetically stir for 1 hour. Pour the above mixture into a 100ml corrosion-resistant stainless steel hydrothermal reactor at room temperature, raise the temperature to 160°C, and seal the reaction for 48h. Centrifuge the suspension, wash the solid with distilled water, and finally dry it at 60°C for 12 hours to obtain cadmium sulfide powder. The obtained 0.50g cadmium sulfide powder, and 0.60g sodium molybdate, 0.40g selenium powder are joined in the middle of 5ml hydrazine hydrate and 55ml deionized water (cadmium sulfide: sodium molybdate: selenium powder: hydrazine hydrate: the mass ratio of water is :100:120:80:1000:11000), magnetic stirring for 0.5h. Pour the above mixture into a 100ml corrosion-resistant stainless steel hydrothermal reactor at room temperature, raise the t...

preparation Embodiment 3

[0029] Add 4.5g of cadmium chloride hydrate, 4.5g of thiourea and 60g of ethylenediamine solution (mass ratio of cadmium chloride hydrate: thiourea: ethylenediamine: 100:100:1333) into the beaker, and magnetically stir for 1 hour. Pour the above mixture into a 100ml corrosion-resistant stainless steel hydrothermal reactor at room temperature, raise the temperature to 160°C, and seal the reaction for 48h. Centrifuge the suspension, wash the solid with distilled water, and finally dry it at 60°C for 12 hours to obtain cadmium sulfide powder. The obtained 0.5g cadmium sulfide powder, and 0.60g sodium molybdate, 0.40g selenium powder are joined in the middle of 10ml hydrazine hydrate and 50ml deionized water) cadmium sulfide: sodium molybdate: selenium powder: hydrazine hydrate: the mass ratio of water is :100:120:80:2000:10000), magnetic stirring for 1h. Pour the above mixture into a 100ml corrosion-resistant stainless steel hydrothermal reactor at room temperature, raise the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com