Preparation method of porous carbon skeleton tin-coated composite electrode material

A composite electrode and porous carbon technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of time and energy consumption, poor specific capacity and rate characteristics, complicated preparation operations, etc., to increase chemical reaction sites, The effect of reducing charge transfer impedance and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

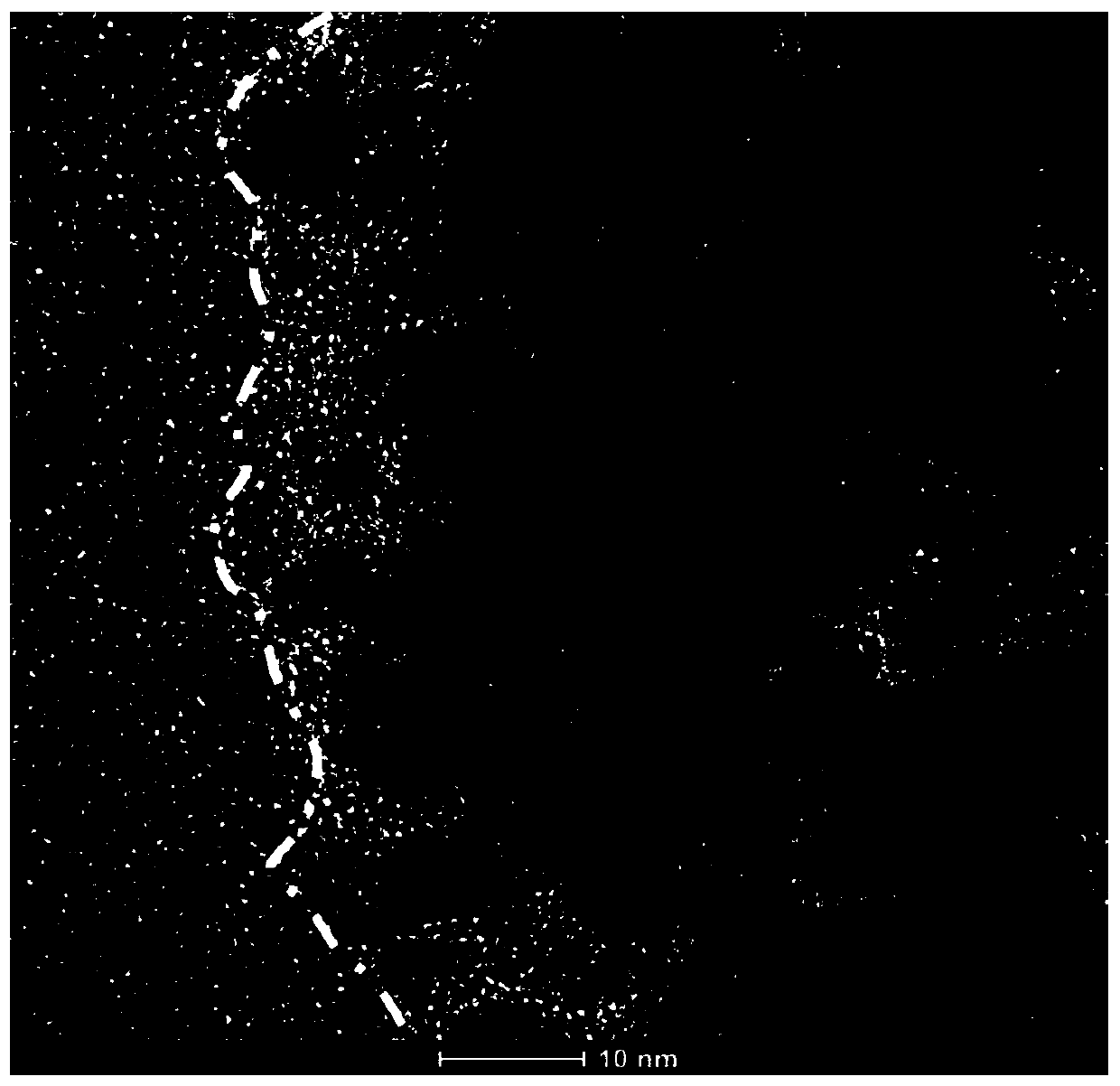

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing an N-doped porous tin-carbon anode material for lithium ion batteries. The method takes into account the performance of the material and the synthesis process and its cost. The raw materials include anhydrous tin tetrachloride, acrylamide, N,N'-methylenebisacrylamide, ammonium persulfate; specifically including the following steps:

[0033] (1) Using anhydrous tin tetrachloride as the tin source, measure an appropriate amount of anhydrous tin tetrachloride and dissolve it in deionized water, form a uniform transparent solution under stirring conditions, and prepare a 2.8mol / L tin chloride aqueous solution. Place to cool;

[0034] (2) Add acrylamide, N,N'-methylenebisacrylamide and ammonium persulfate to 20ml of tin tetrachloride aqueous solution, wherein the mass ratio of acrylamide to anhydrous tin tetrachloride is 1:15, The amount of ammonium persulfate used is 2.5% of the mass of acrylamide, and the mass ratio of N,N'-methy...

Embodiment 2

[0038] This embodiment provides a method for preparing an N-doped porous tin-carbon anode material for lithium ion batteries. The method takes into account the performance of the material and the synthesis process and its cost. The raw materials include anhydrous tin tetrachloride, acrylamide, N,N'-methylenebisacrylamide, sodium persulfate; specifically including the following steps:

[0039] (1) Using anhydrous tin tetrachloride as the tin source, measure an appropriate amount of anhydrous tin tetrachloride and dissolve it in deionized water, form a uniform transparent solution under stirring conditions, and prepare a 4.2mol / L tin chloride aqueous solution. Place to cool;

[0040] (2) Add acrylamide, N,N'-methylenebisacrylamide and sodium persulfate to 20ml of tin tetrachloride aqueous solution, where the mass ratio of acrylamide to anhydrous tin tetrachloride is 1:12, The amount of sodium persulfate used is 4% of the mass of acrylamide, and the mass ratio of N,N'-methylenebisyla...

Embodiment 3

[0048] This embodiment provides a method for preparing an N-doped porous tin-carbon anode material for lithium ion batteries. The method takes into account the performance of the material and the synthesis process and its cost. The raw materials include anhydrous tin tetrachloride, acrylamide, N,N'-methylenebisacrylamide, sodium persulfate; specifically including the following steps:

[0049] (1) Using crystalline tin tetrachloride as the tin source, weigh an appropriate amount of crystalline tin tetrachloride and dissolve it in deionized water, form a uniform transparent solution under stirring conditions, prepare a 1.5mol / L tin chloride aqueous solution, and place it to cool ;

[0050] (2) Add acrylamide, N,N'-methylenebisacrylamide and sodium persulfate to 20ml of tin tetrachloride aqueous solution, where the mass ratio of acrylamide to crystalline tin tetrachloride is 1:8. Potassium sulfate and sodium bisulfite (K 2 S 2 O 8 / NaHSO 3 The use amount of) is 1% of the mass of acry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com