Preparation method of carbon nanotube composite lithium iron phosphate anode material

A technology of carbon nanotube composite and lithium iron phosphate, which is applied in the direction of nanotechnology, battery electrodes, electrical components, etc., can solve the problems of poor high-rate charge and discharge performance, unstable structure, decomposition, etc., and achieve good rate and low-temperature performance, Favorable effect of wetting, improvement of electronic conductivity and ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

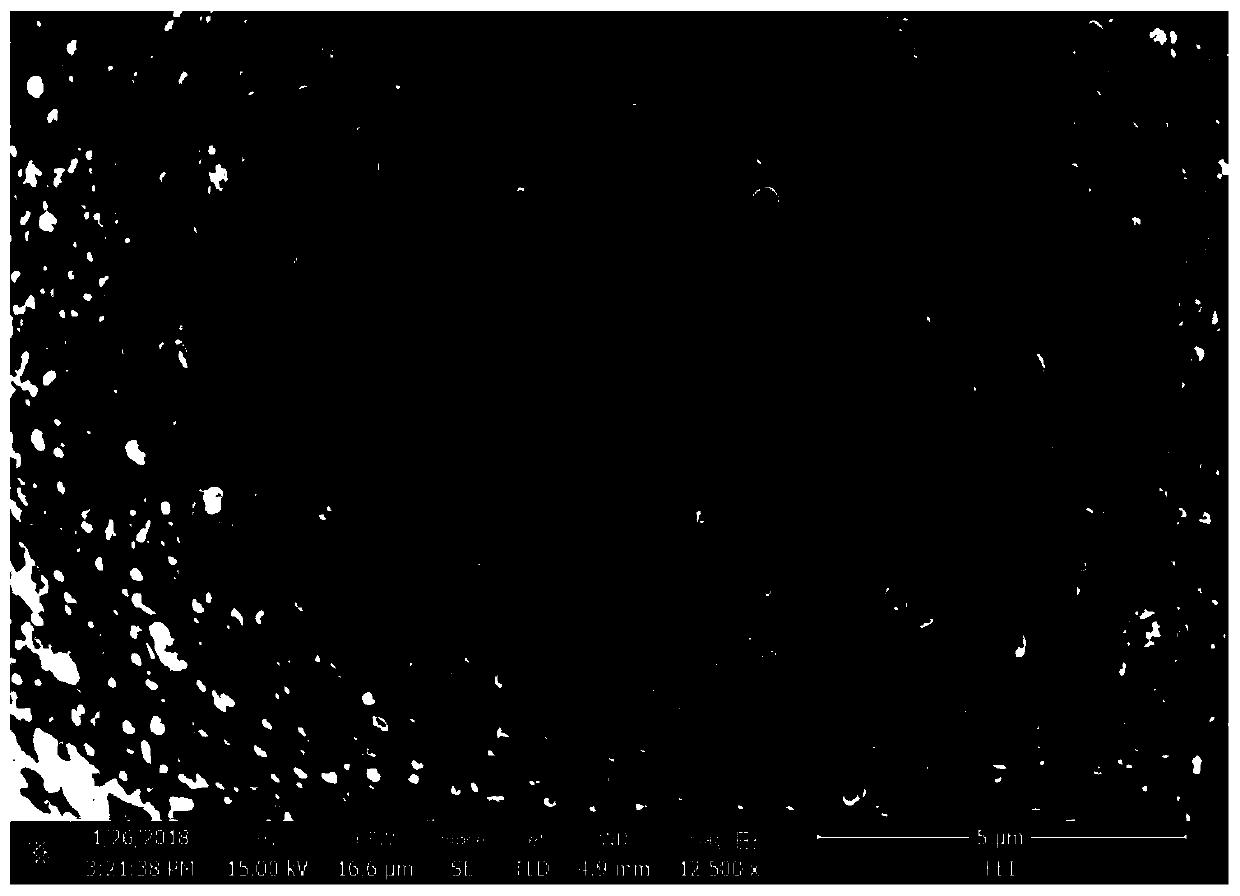

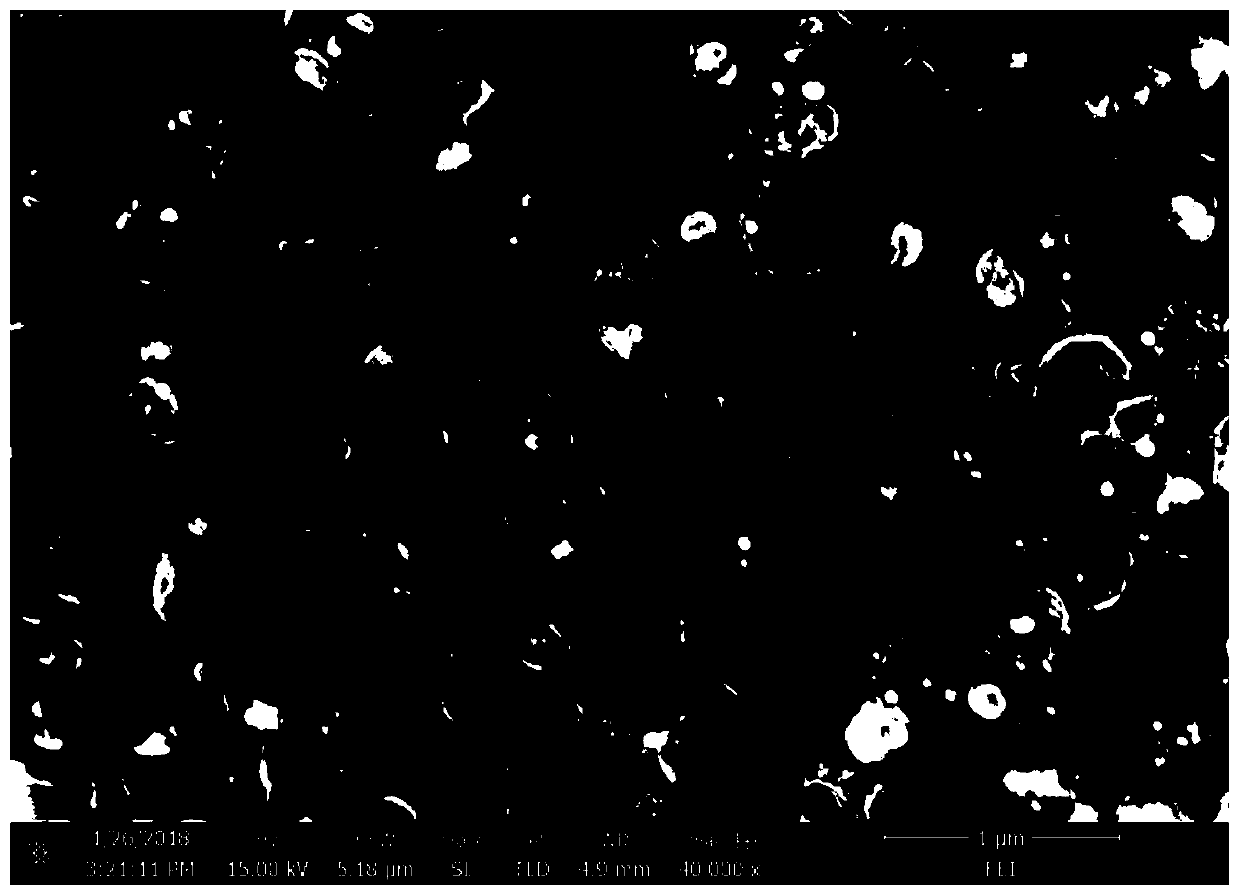

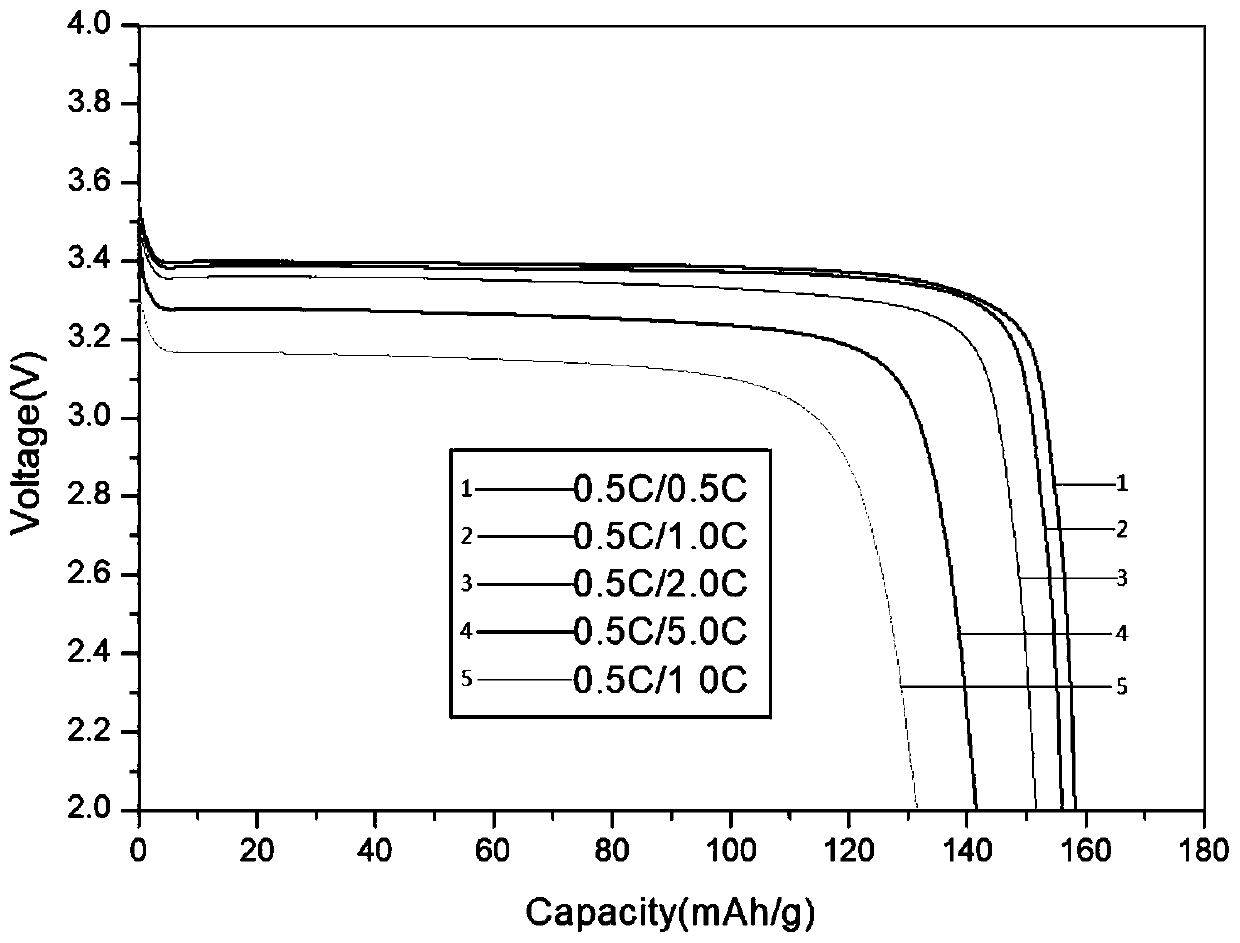

[0037] In the present embodiment, weigh 7200g anhydrous ferric phosphate (FePO 4 ), 1818g lithium carbonate (Li 2 CO 3 ), 720g glucose, 36g carbon nanotube dry powder and 180g polyvinylpyrrolidone (PVP). Add 20,000g of deionized water to the stainless steel kettle, and slowly pour in all the FePO while stirring 4 and Li 2 CO 3 Disperse for 30min. Continue to slowly add glucose, carbon nanotube dry powder and PVP and stir for 30 minutes to obtain a light yellow slurry. All the above-mentioned slurry was transferred to a stirring ball mill for ball milling, and then ground by a pin-type sand mill to obtain a slurry with an average particle size of 350 nm, that is, a precursor slurry. The precursor slurry is transported to the spray dryer under constant stirring, the inlet temperature is set to 240° C., the outlet temperature is set to 100° C., and a pale yellow precursor powder can be obtained from the powder collector. Put the precursor powder into a sagger, place it in ...

Embodiment 2

[0042] In the present embodiment, weigh 7200g anhydrous ferric phosphate (FePO 4 ), 1818g lithium carbonate (Li 2 CO 3 ), 600g sucrose, 57.6g carbon nanotube dry powder and 180g polyvinylpyrrolidone (PVP). Add 22000g deionized water to the stainless steel kettle, and slowly pour all the FePO 4 and Li 2 CO 3 Disperse for 30min. Continue to slowly add sucrose, carbon nanotube dry powder and PVP and stir for 30 minutes to obtain a light yellow slurry. All the above-mentioned slurry was transferred to a stirring ball mill for ball milling, and then ground by a pin-type sand mill to obtain a slurry with an average particle size of 300 nm, that is, a precursor slurry. The precursor slurry was transported to the spray dryer under constant stirring, the inlet temperature was set at 250° C., the outlet temperature was set at 105° C., and a light yellow precursor powder could be obtained from the powder collector. Put the precursor powder into a sagger, place it in a sintering fu...

Embodiment 3

[0046] In the present embodiment, weigh 7200g anhydrous ferric phosphate (FePO 4 ), 1818g lithium carbonate (Li 2 CO 3 ), 720g soluble starch, 720g carbon nanotube slurry (solid content 5%) and 160g polyethylene glycol (PEG). Add 21000g of deionized water to the stainless steel kettle, and slowly pour all the FePO 4 and Li 2 CO 3 Disperse for 30min. Continue to slowly add soluble starch, carbon nanotube slurry and PEG and stir for 30 minutes to obtain light yellow slurry. All the above-mentioned slurry was transferred to a stirring ball mill for ball milling, and then ground by a pin-type sand mill to obtain a slurry with an average particle size of 350 nm, that is, a precursor slurry. The precursor slurry is transported to the spray dryer under constant stirring, the inlet temperature is set to 250° C., and the outlet temperature is set to 110° C. A light yellow precursor powder can be obtained from the powder collector. Put the precursor powder into a sagger, place it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com