Preparation method of supercapacitor

A supercapacitor, gel electrolyte technology, applied in the direction of hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, nanotechnology for materials and surface science, etc., can solve unsatisfactory charge storage capacity, specific capacitance and Problems such as low energy density and unsatisfactory charge-discharge stability have achieved the effects of facilitating large-scale development and application, excellent rate performance, excellent rate performance and repeated charge-discharge stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

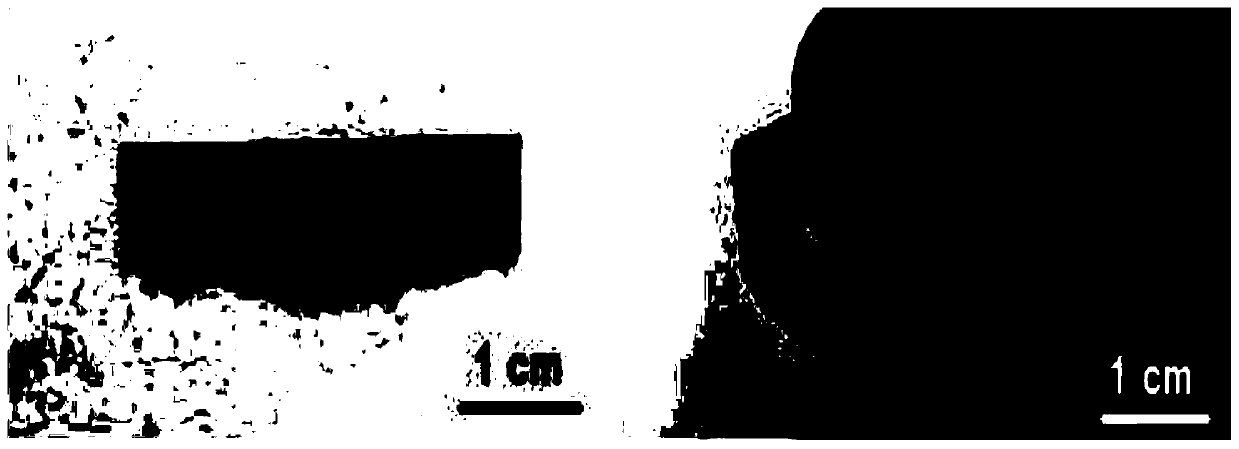

[0028] A preparation method for a flexible composite film for supercapacitors, as follows:

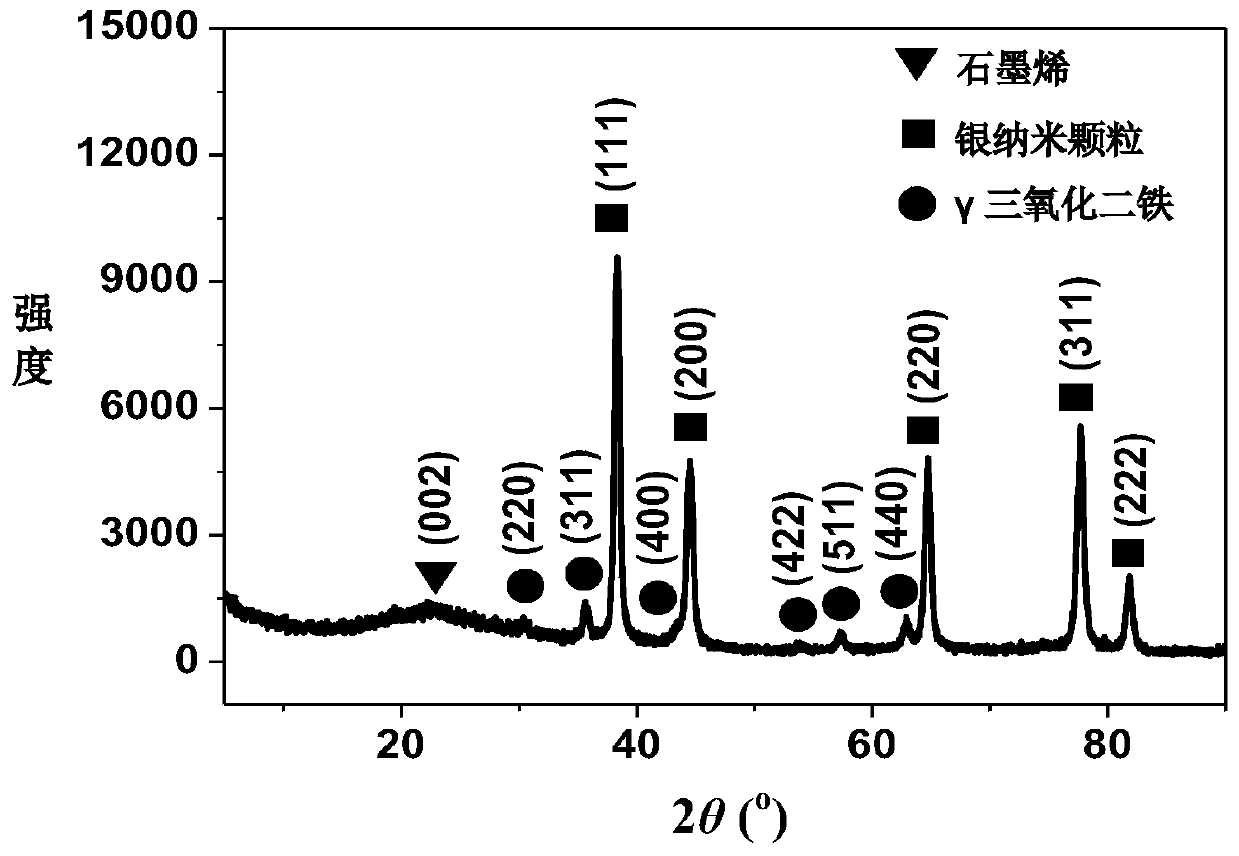

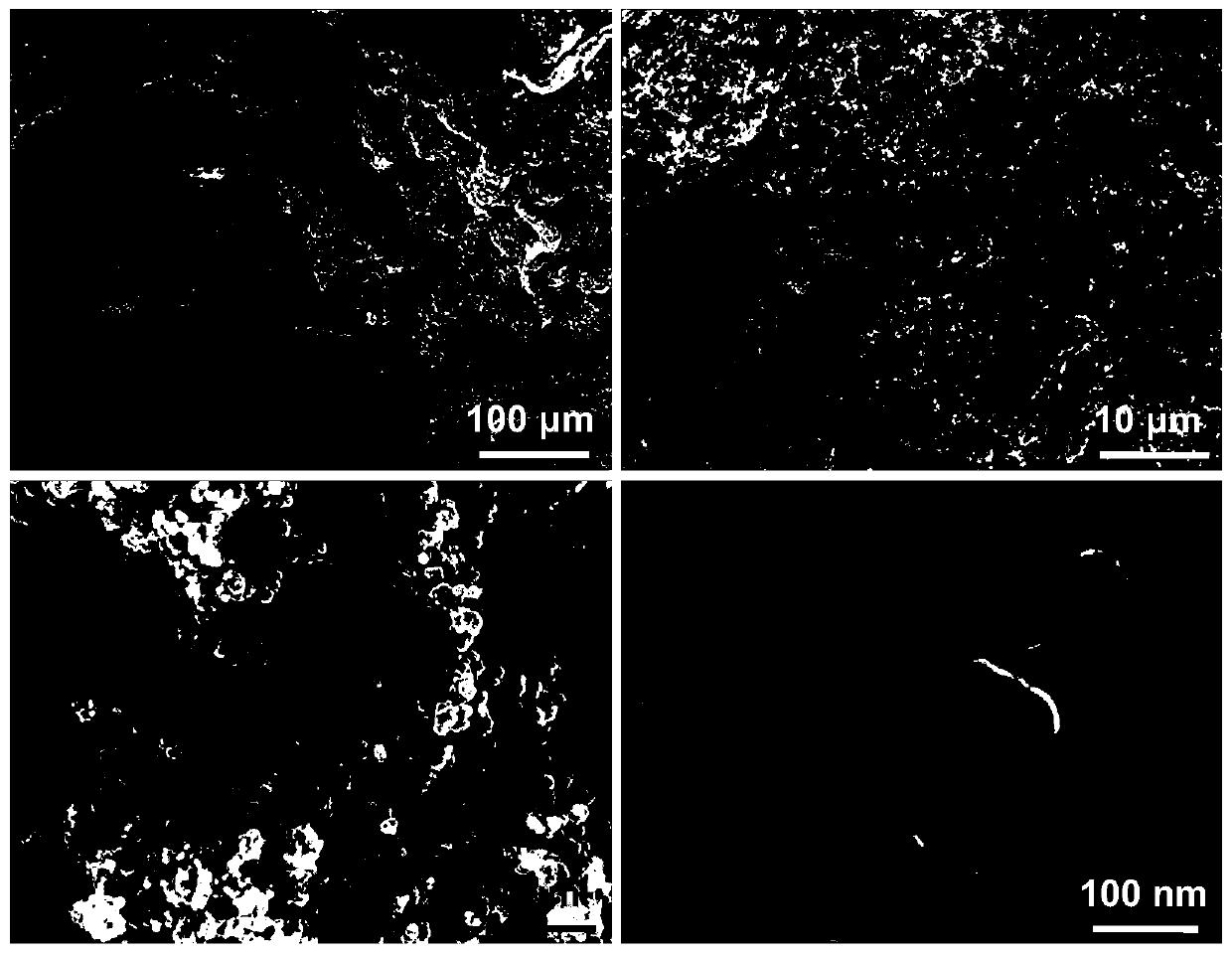

[0029] The previously developed cellulose / graphene / silver nanoparticle film was cut into 0.5 cm × 3 cm rectangular strips, and then immersed in a temperature of 60 o C at a concentration of 10 mM FeSO 4 in the aqueous solution for 30 s, then quickly removed and placed at a temperature of 60 o The concentration of C is 20 mM KOH aqueous solution for 30 s, which is 1 deposition cycle. According to this method, after we repeatedly and alternately deposit 60 cycles, we can deposit γ-crystalline ferric oxide nanoparticles on the cellulose / graphene / silver nanoparticle film to obtain cellulose / graphene / silver nanoparticle film. Particle / Fe2O3 composite film.

[0030] Use it directly as a flexible electrode for electrochemical testing:

[0031] (1) The above-prepared cellulose / graphene / silver nanoparticles / ferric oxide composite film was taken out from the solution, then washed repeatedly ...

Embodiment 2

[0036] A kind of preparation of supercapacitor, make according to the following steps:

[0037] 1. Preparation of polyvinyl alcohol / potassium hydroxide gel electrolyte: Add 6 g of polyvinyl alcohol to 60 mL of water, raise the temperature to 90°C, stir for 30 minutes to dissolve it, and then cool naturally to 20°C. Next slowly add 3 mL of 2 gmL dropwise with stirring −1 The aqueous solution of potassium hydroxide is stirred evenly to obtain a clear and transparent polyvinyl alcohol / potassium hydroxide gel electrolyte;

[0038] 2. the preparation of the cellulose / graphene / silver nanoparticle / ferric oxide film that contains gel film: the cellulose / graphene / silver nanoparticle / ferric oxide composite film that make in embodiment 1 is cut A rectangular strip with a size of 0.5 cm × 3 cm was placed on a glass slide, and then the polyvinyl alcohol / potassium hydroxide gel electrolyte was poured on its surface, leaving a blank area of 0.5 cm × 1 cm for contact with the electrode cl...

Embodiment 3

[0041] A kind of preparation of supercapacitor, make according to the following steps:

[0042] 1. Preparation of polyvinyl alcohol / potassium hydroxide gel electrolyte: Add 6 g of polyvinyl alcohol to 60 mL of water, raise the temperature to 85°C, stir for 35 minutes to dissolve it, and then cool naturally to 25°C. Next slowly add 3 mL of 2 gmL dropwise with stirring −1 The aqueous solution of potassium hydroxide is stirred evenly to obtain a clear and transparent polyvinyl alcohol / potassium hydroxide gel electrolyte;

[0043] 2. the preparation of the cellulose / graphene / silver nanoparticle / ferric oxide film that contains gel film: the cellulose / graphene / silver nanoparticle / ferric oxide composite film that make in embodiment 1 is cut A rectangular strip with a size of 0.5 cm × 3 cm was placed on a glass slide, and then the polyvinyl alcohol / potassium hydroxide gel electrolyte was poured on its surface, leaving a blank area of 0.5 cm × 1 cm for contact with the electrode cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com